Preparation process of persistent antibacterial and antiviral additive

An antiviral additive and preparation technology, applied in the direction of disinfectants, bactericides, biocides, etc., can solve the problems of high cost of artificial material resources, no independent antibacterial and antiviral functions, etc., achieve long-lasting antivirus ability, avoid changes in chemical properties, The effect of long-lasting virucidal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

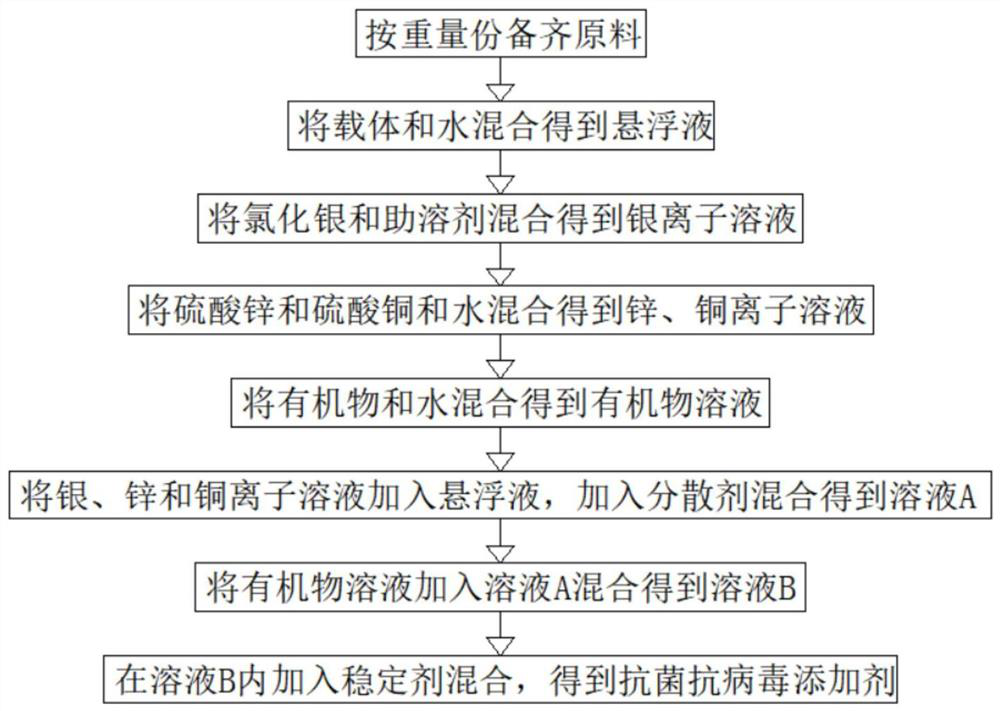

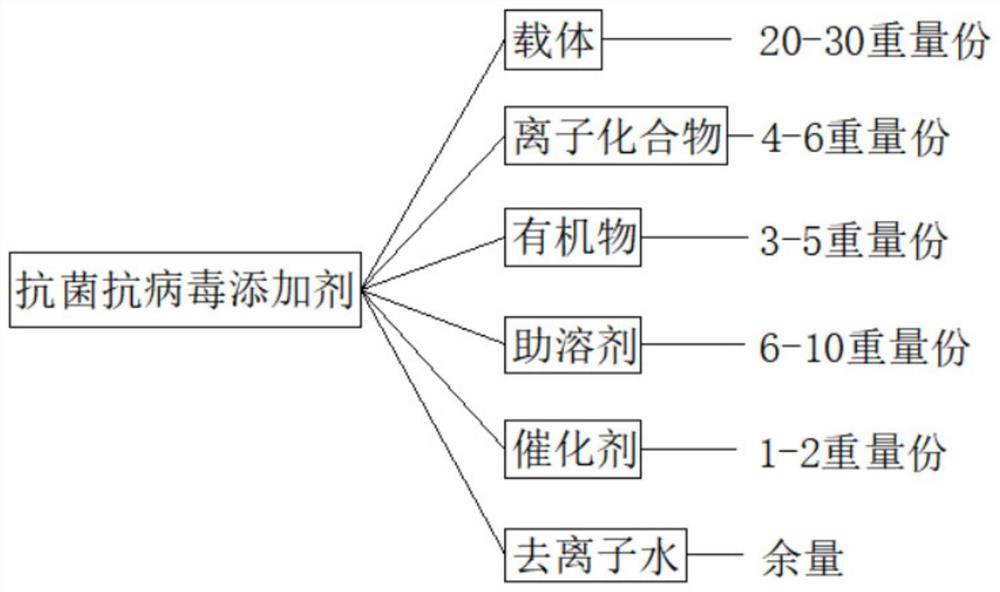

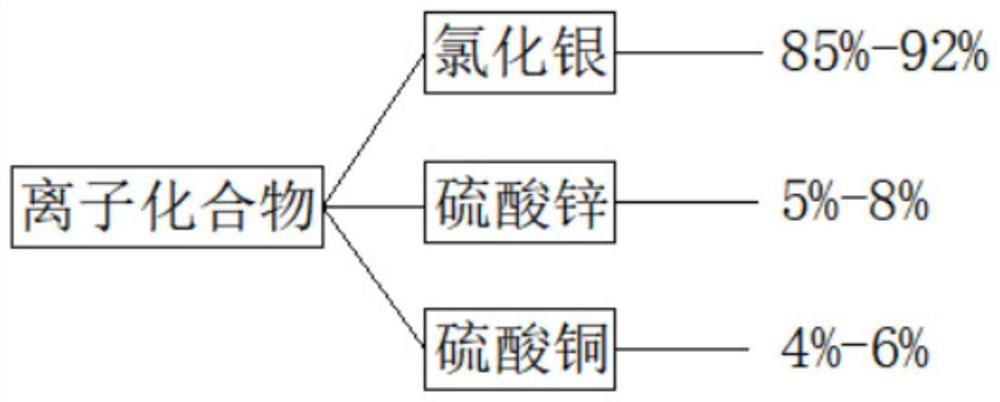

[0038] refer to Figure 1-5 , a preparation process for persistent antibacterial and antiviral additives, comprising the following raw materials in parts by weight: 20-30 parts by weight of carriers, 4-6 parts by weight of ionic compounds, 3-5 parts by weight of organic matter, 6-10 parts by weight of part of co-solvent, 1-2 parts by weight of catalyst and the balance of deionized water, the carrier is a polymer adsorption material, the ionic compound includes silver chloride, zinc sulfate and copper sulfate, and the organic matter includes di Sodium chloroisocyanurate and benzalkonium bromide, the cosolvent is a thiosulfuric acid solution, and the catalyst includes a dispersant, a defoamer and a stabilizer;

[0039] Concrete preparation process comprises the following steps:

[0040] S1: Prepare all required raw materials by weight;

[0041] S2: Take a certain amount of deionized water, mix the carrier and deionized water, and stir for a certain period of time to form a sus...

Embodiment 2

[0057] refer to Figure 1-5 , a preparation process for persistent antibacterial and antiviral additives, comprising the following raw materials in parts by weight: 25 parts by weight of carriers, 5 parts by weight of ionic compounds, 4 parts by weight of organic matter, 8 parts by weight of cosolvents, 1.5 parts by weight of Catalyst and the remaining deionized water, the carrier is a polymer adsorption material, the ionic compound includes silver chloride, zinc sulfate and copper sulfate, and the organic matter includes sodium dichloroisocyanurate and benzalkonium bromide, Described cosolvent is thiosulfuric acid solution, and described catalyst comprises dispersant, defoamer and stabilizer, and described dispersant is the composition of stearylamide and higher alcohol, and described defoamer is polydimethylsiloxane Oxygen, the stabilizer is a calcium-zinc composite metal soap stabilizer;

[0058] Concrete preparation process comprises the following steps:

[0059] S1: Pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com