Preparation method of Ectoine-based palladium-carbon catalyst

A technology of palladium carbon catalyst and ectoine, which is applied in the field of precious metals, can solve the problem of poor loading effect of palladium carbon catalyst and achieve the effect of reducing ammonia pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

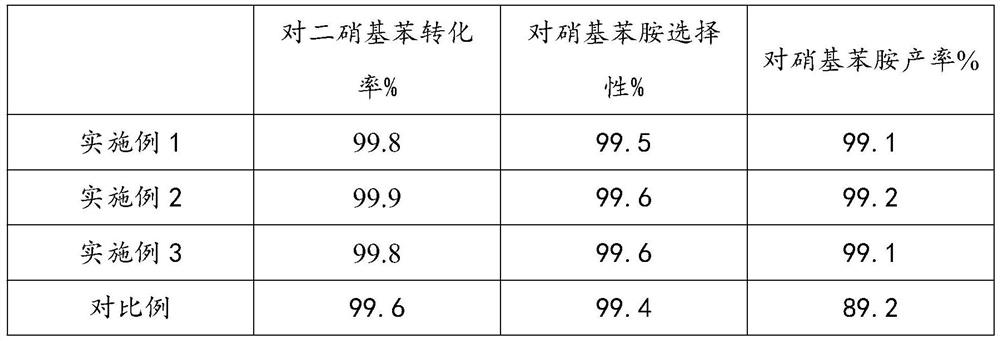

Examples

Embodiment 1

[0020] A method of preparing a catalyst by palladium carbon usually caused by gram-based, comprising the steps of:

[0021] Step one, the activated carbon support was pretreated to give a clean and dry activated carbon; said pretreatment comprises the steps of: a1 activated carbon was added to an aqueous solution of ethanol ultrasonic 10min, the volume concentration of ethanol is 50% aqueous ethanol solution. , the temperature of the ultrasound is 40 ℃, a2, ultrasound into the activated carbon impregnated with a solution of hydrochloric acid in 10min, 20min and then immersed in an alkaline solution is added to give the activated carbon, pH 3 to the hydrochloric acid solution, the alkaline solution aqueous ammonia solution, and a pH of 9;

[0022] Step 2, palladium acetate acetone solution was added to a stirred uniformly form a palladium - acetone solution, and then the activated carbon was added, and the low temperature water bath, a microwave reactor IH, remove the dry film obta...

Embodiment 2

[0028] A method of preparing a catalyst by palladium carbon usually caused by gram-based, comprising the steps of:

[0029]Step 1, the active carbon carrier is pre-treatment, and clean activated activated carbon; the pretreatment comprises the step of: A1. Add activated carbon to an ethanol 20min, the ethanol volume concentration of the ethanol solution is 70%. The ultrasonic temperature is 60 ° C, A2, and the ultrasound active carbon is placed in a hydrochloric acid solution for 20 min, then the alkaline solution is immersed in an alkaline solution to obtain activated activated carbon, the pH of the hydrochloric acid solution 4, the alkaline solution It is aqueous ammonia solution, and the pH is 10;

[0030] Step 2, the palladium acetate is added to the acetone solution to stir well, then the activated activated carbon is added, and the activated activated carbon is added, and the microwave reaction is 3 h, and the drying is dried to obtain a coated palladium-activated carbon, an...

Embodiment 3

[0036] A method of preparing a palladium carbon catalyst based on Ike, including the following steps:

[0037] Step 1, the active carbon carrier is pre-treatment, and clean activated activated carbon; the pretreatment includes the step of: A1. Add activated carbon to an ethanol solution of 15 min, the ethanol volume concentration of the ethanol aqueous solution is 60%. The ultrasonic temperature is 50 ° C, A2, and the ultrasound active carbon is placed in a hydrochloric acid solution for 15 min, then the alkaline solution is immersed in an alkaline solution to obtain activated activated carbon, the pH of the hydrochloric acid solution is 4, the base The sex solution is an aqueous solution, and the pH is 9;

[0038] Step 2, the palladium acetate is added to the acetone solution and stirred and uniformly forms a palladium-acetone liquid, and then activated activated carbon is added, and a low-temperature water bath microwave reaction is 2 h, and the drying is dried to obtain a coate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com