Coal gangue raw material treatment device for coal gangue brick production

A technology for raw material processing and coal gangue, which is applied in grain processing, solid separation, filter screening, etc., can solve the problems of easy clogging of the filter screen, easy adhesion to the filter screen, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

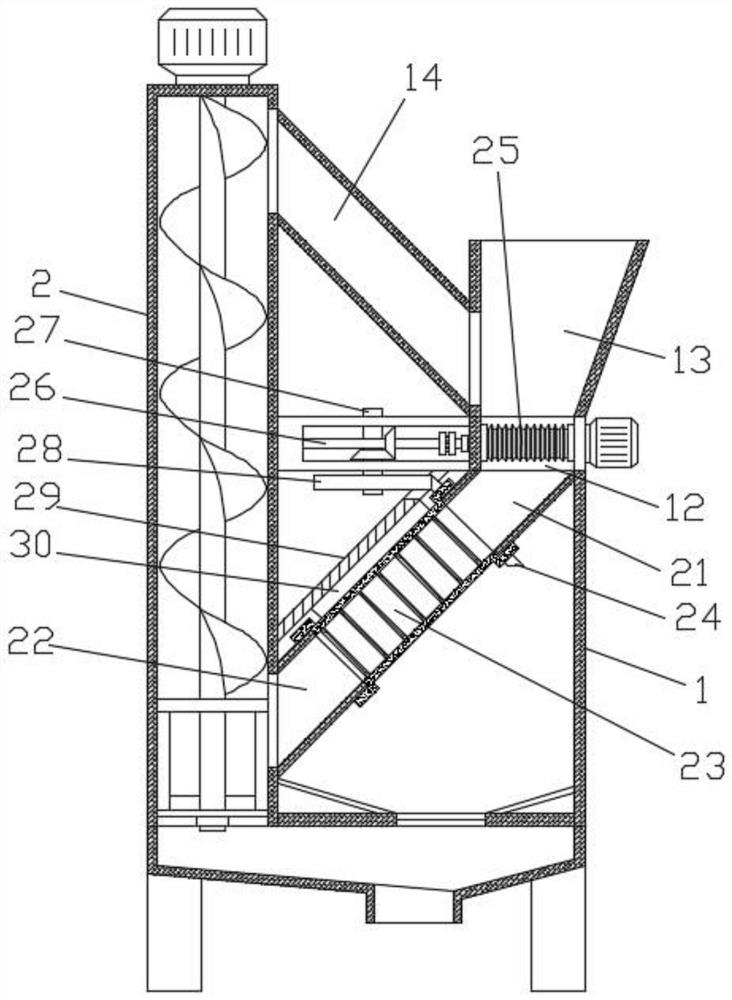

[0023] like figure 1 Shown; A coal gangue raw material processing device for coal gangue brick production, comprising:

[0024] Processing box 1, the upper part of the processing box 1 is provided with a crushing box 12, and the upper part of the crushing box 12 is provided with a feeding hopper 13;

[0025] The lifting cylinder 2, the upper end of the lifting cylinder 2 is connected with a return channel 14, and the return channel 14 communicates with the feed hopper 13;

[0026] The lower part of the crushing box 12 is provided with a first connecting sleeve 21, and the lower part of the lifting cylinder 2 is equipped with a second connecting sleeve 22. The first connecting sleeve 21 and the second connecting sleeve 22 are arranged coaxially. A filter cylinder 23 is rotated between the second connecting sleeves 22. A drive gear ring 24 is installed at one end of the filter cylinder 23. A crushing roller 25 is installed inside the crushing box 12. The crushing roller 25 is d...

Embodiment 2

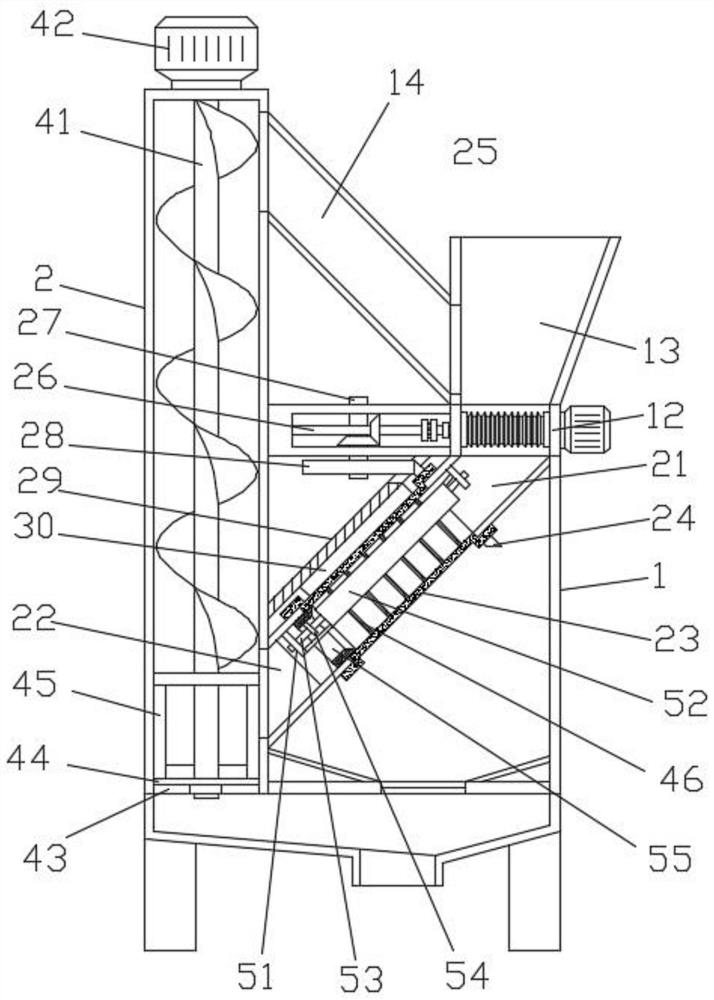

[0031] On the basis of Example 1, such as figure 2 As shown; the coal gangue material of unqualified particle size derived by the filter cylinder 23 flows into the lifting cylinder 2 through the second support sleeve, and the internal lifting screw 41 of the lifting cylinder 2 rotates to lift the coal gangue fragments. In this process, In the case of a large amount of broken materials, among the pulverized coal gangue passing through the filter cylinder 23, some of the crushed materials with qualified particle sizes cannot pass through the filter cartridge 23 in time, and this part of the crushed materials with qualified particle sizes will pass through the lifting cylinder again. 2 Lift it into the crusher for crushing again, this part of the crushed material is mixed into the crusher again, it is easy to fill the gap of the crushed material in the crusher and affect the crushing effect of the crusher, so by installing the lifting screw in the lifting cylinder 2 41, the lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com