A kind of biodegradable composite bead foam material and preparation method thereof for packaging field

A technology of biodegradation and bead foaming, applied in packaging, wrapping paper, biological packaging, etc., can solve the problems of low foaming ratio, toxic foaming agent, expensive nucleating agent, etc., and achieve foaming saturation time The effect of short length, improved production efficiency, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Take 70 ℃, after drying for 10h (80% by weight), low crystallinity PLA-LX175 (18% by weight), compatibilizer ADR-4468 (weight fraction 2%), extruded in a twin-screw underwater pelletizing extruder, which contains nine temperature zones, the temperatures from zone one to zone nine are 155°C, 180°C, 180°C, 185°C, 185°C, 190°C, 190°C, 185°C, 190°C, die temperature 230°C, screw speed 80 rpm; pelletizer speed 1500 rpm / min, cut into 5 mg particles.

[0036] (2) The obtained particles are placed in a supercritical molding foaming machine to ensure that the total volume of the particles does not exceed 1 / 3 (3000 cm) of the container volume. 3 ), at 20MPa supercritical CO2 As a foaming agent, it was saturated at 115 °C for 10 min, and the pressure was released at a rate of 20 MPa / s to obtain a biodegradable composite foamed material.

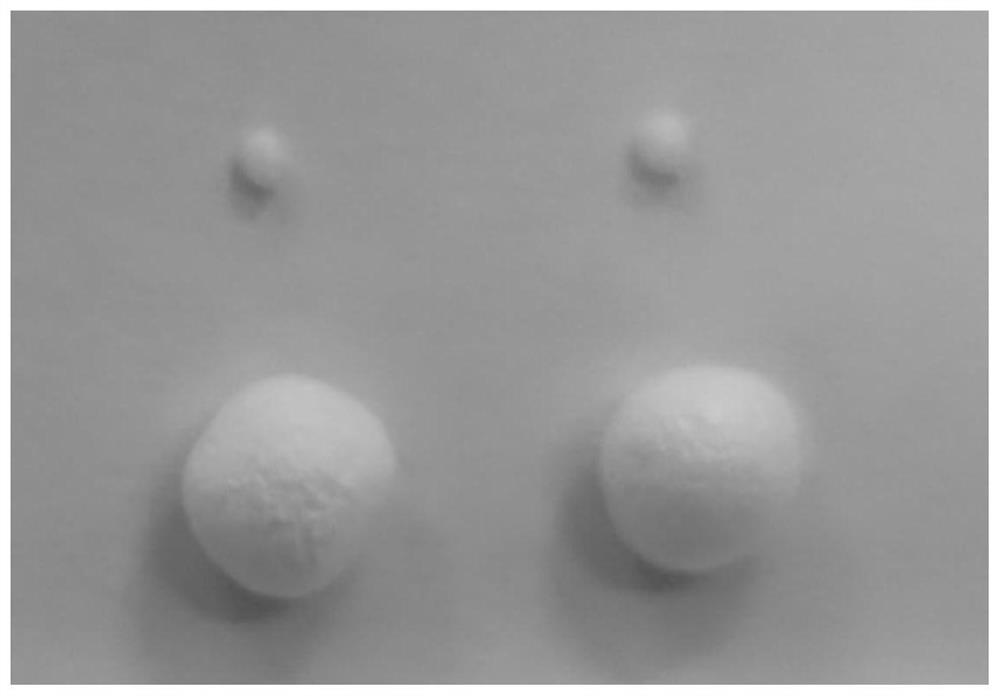

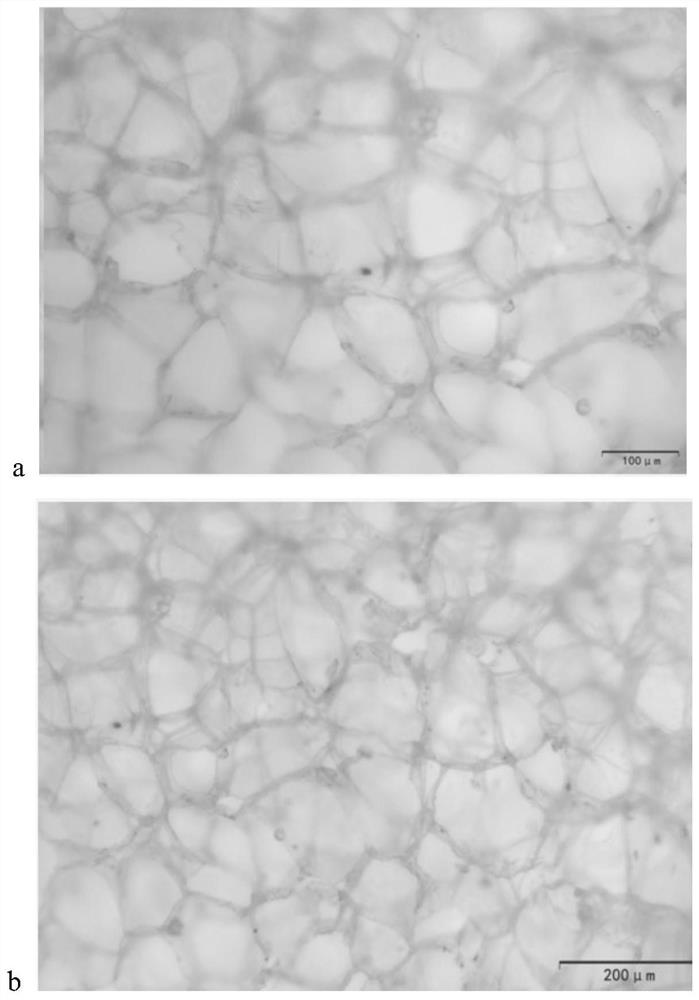

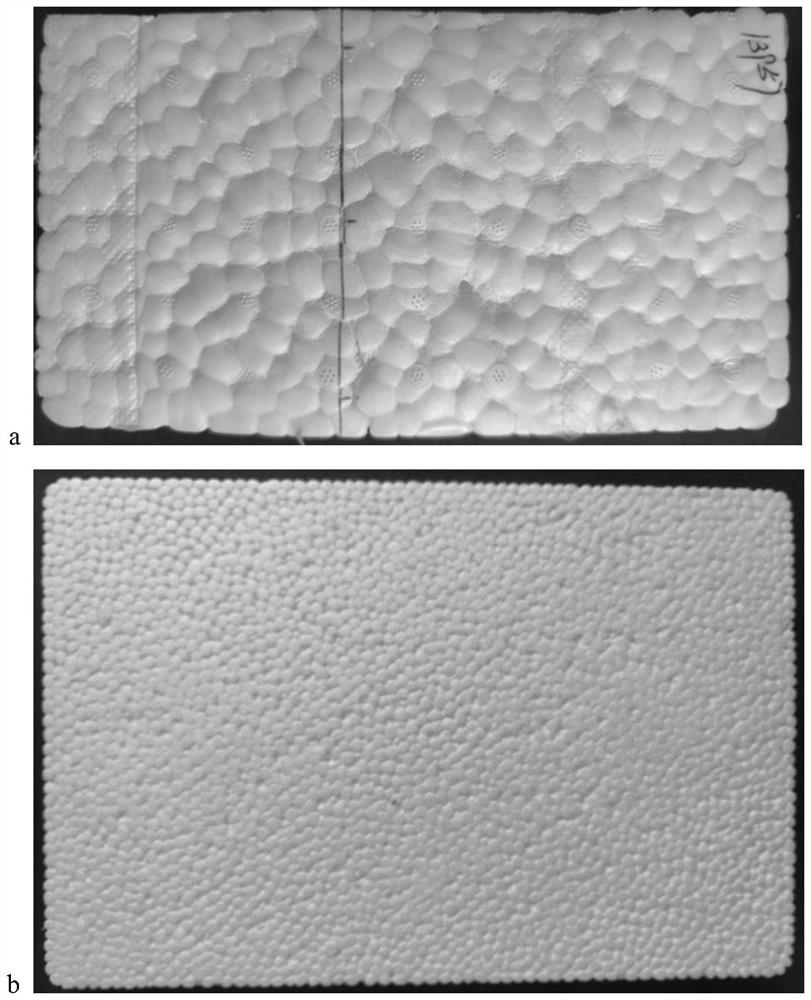

[0037] figure 1 It is a comparison diagram of the obtained particles before and after foaming in Example 1 (that is, the particles obtai...

Embodiment 2

[0044] Take 70 ℃, after drying for 10h (70% by weight), low crystallinity PLA-LX175 (27% by weight), compatibilizer (3% by weight), extruded in a twin-screw underwater pelletizing extruder, which contains nine temperature zones, and the temperatures from zone one to zone nine are 155°C, 180°C, 180°C, 185°C, 185°C, 190°C, 190°C, 185°C, 190°C, die temperature 230°C, screw speed 80 rpm; pelletizer speed is 1500 rpm / min twin-screw underwater pelletizing extruder, cut into 5mg pellets .

[0045] The obtained particles are placed in a supercritical molding foaming machine to ensure that the total volume of the particles does not exceed 1 / 3 (3000cm) of the container volume. 3 ), with a total of 20MPa supercritical N 2 and supercritical CO 2 The composite gas is a blowing agent, and its supercritical N 2 and supercritical CO 2 The ratio is 1:3, and the biodegradable composite foam material is obtained by saturating for 10 min at 115 °C, and releasing the pressure at a rate of ...

Embodiment 3

[0051] Take 70 ℃, after drying for 10h (90% by weight), low crystallinity PLA-LX175 (8% by weight), compatibilizer ADR-4468 (weight fraction 2%), extruded in a twin-screw underwater pelletizing extruder, which contains nine temperature zones, the temperatures from zone one to zone nine are 155°C, 180°C, 180°C, 185°C, 185°C, 190°C, 190°C, 185°C, 190°C, die temperature 230°C, screw speed 80 rpm; pelletizer speed 1500 rpm / min twin-screw underwater pelletizing extruder, cut into 5mg of particles.

[0052] The obtained particles are placed in a supercritical molding foaming machine to ensure that the total volume of the particles does not exceed 1 / 3 (3000cm) of the container volume. 3 ), with a total of 15MPa of supercritical N 2 and supercritical CO 2 The composite gas is a blowing agent, and its supercritical N 2 and supercritical CO 2 The ratio is 1:3, and the biodegradable composite foam material is obtained by saturating for 30 min at 110 °C and releasing the pressure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com