Environment-friendly noise-reduction energy-saving device for electromagnetic brake

An electromagnetic brake and energy-saving device technology, applied in the direction of brake type, brake components, brake disc, etc., can solve the problems of increasing impact force, affecting the braking performance of the brake disc, noise, etc., to reduce friction and resistance, Good for health and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

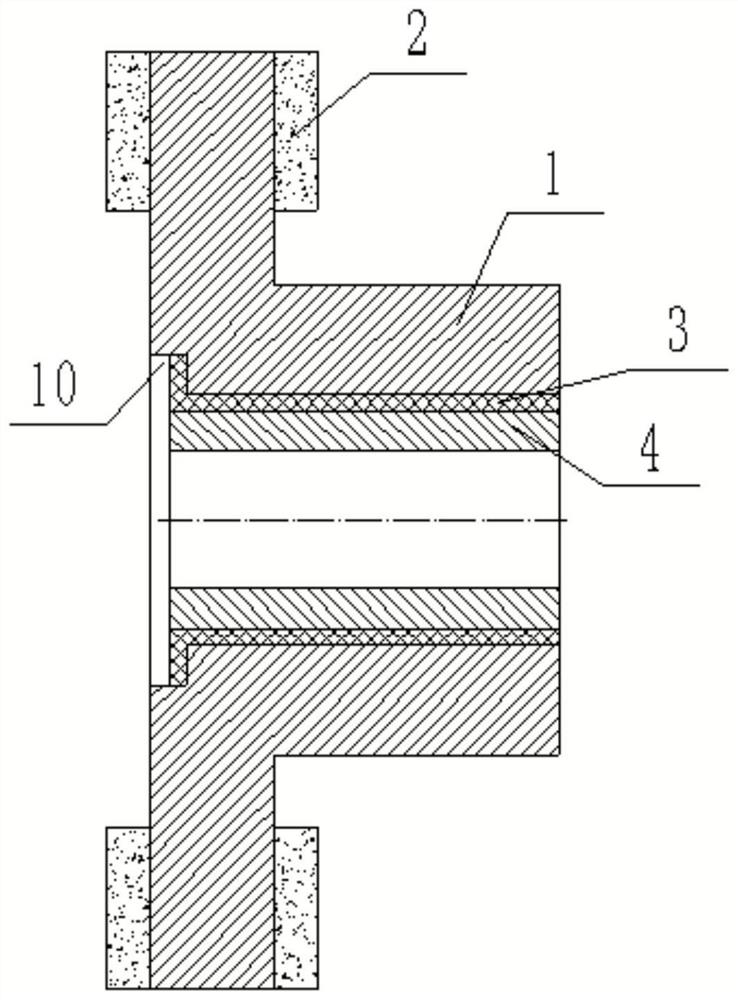

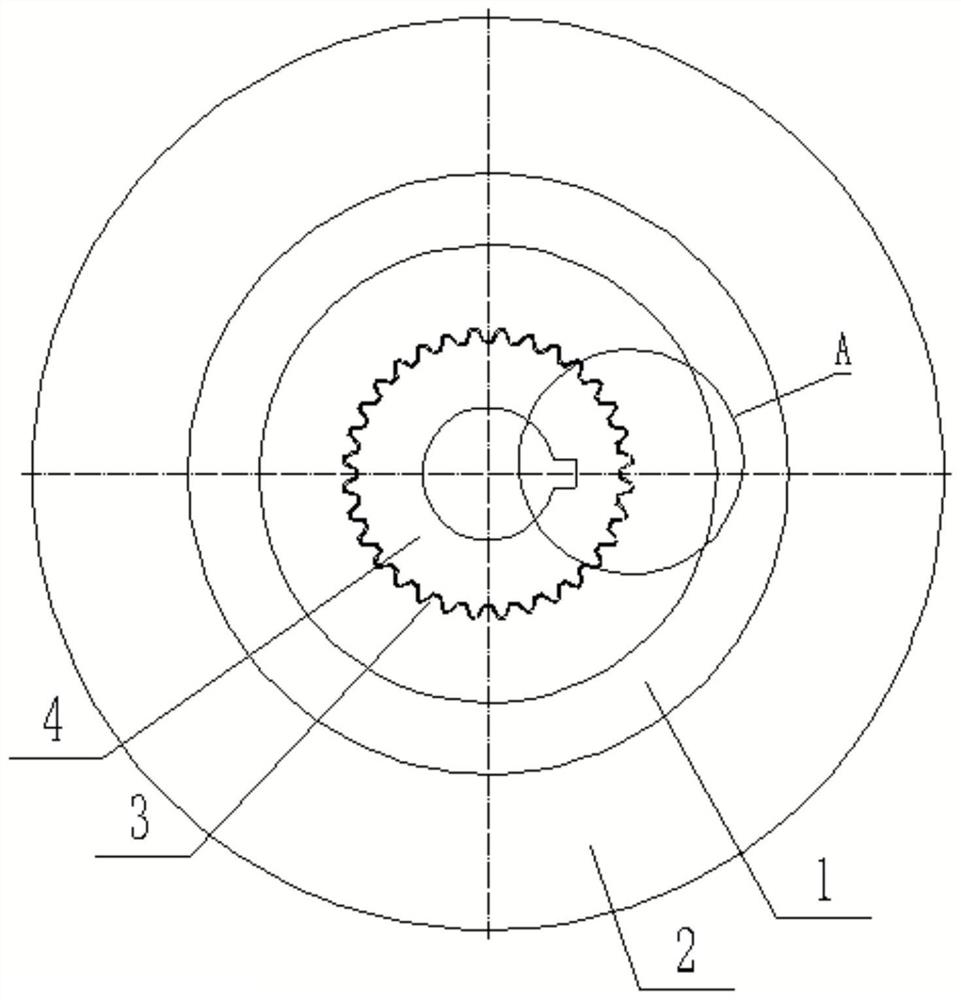

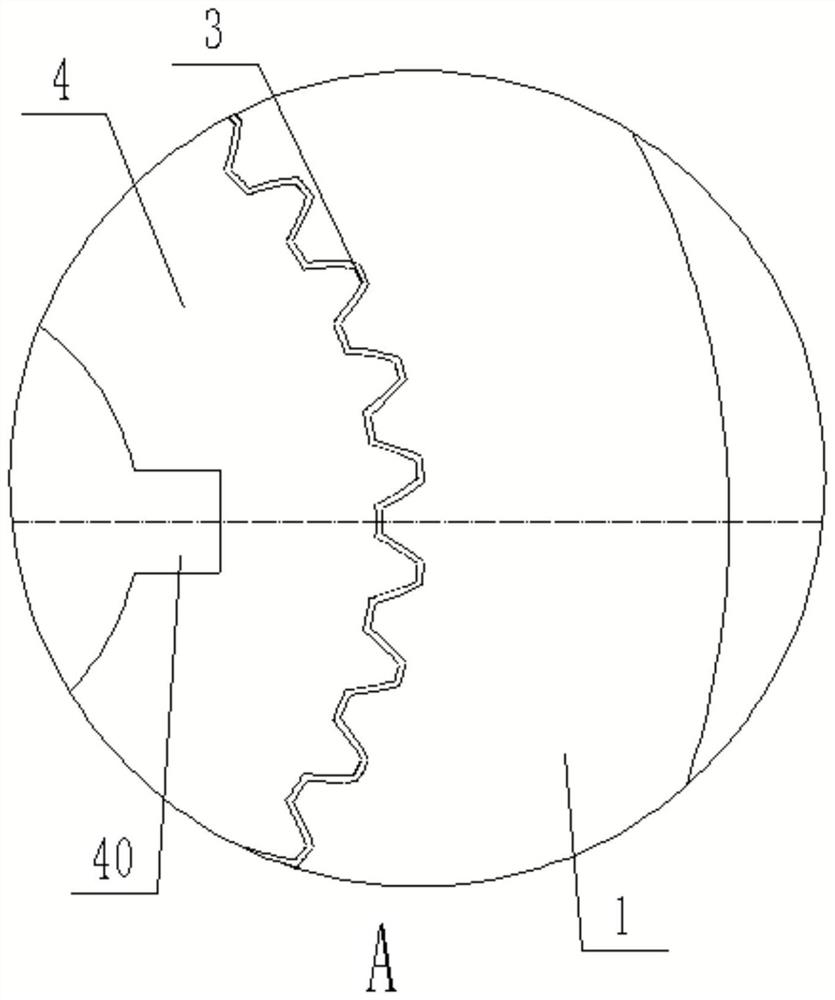

[0035] see Figure 1-Figure 6 shown,

[0036] This embodiment provides an environmentally friendly, noise-reducing and energy-saving device for an electromagnetic brake, including a brake disc base 1, a brake disc 2, a wear-resistant and noise-reducing spline sleeve 3, and a hollow spline shaft 4; the brake disc 2 and The brake disc base 1 is bonded or vulcanized together; the brake disc base 1 is disc-shaped with a boss, and the center of the brake disc base 1 is provided with a spline hole; inside the spline hole The wear-resistant and noise-reducing spline sleeve 3 is socketed; the wear-resistant and noise-reducing spline sleeve 3 is a hollow cylinder, and the inner and outer sides of the wear-resistant and noise-reduction spline sleeve 3 are provided with spline grooves. The number of spline grooves on the surface is equal, similar in shape, and forms a thin-walled structure; the outer spline groove of the wear-resistant and noise-reducing spline sleeve 3 is adapted to th...

Embodiment 2

[0050] Such as Figure 7-10 as shown,

[0051] The structure of this embodiment is basically the same as that of Embodiment 1, and the differences between this embodiment and Embodiment 1 are:

[0052] Such as Figure 7 As shown, when the size of the brake disc 2 is small, for example, the diameter of the brake disc 2 is less than or equal to 60mm, the size of the brake disc base 1 will also become smaller, and its spline hole will also become smaller, and the spline The size of the wear-resistant and noise-reducing spline sleeve 3 matched with the hole will also become smaller, and at this time, the hollow spline shaft 4 will also become smaller; in order to ensure the normal use of the brake disc 2, the shaft matched with the hollow spline shaft 4 cannot If it is too thin, the wall thickness of the flat keyway 40 on the hollow spline shaft 4 will be very thin, which will affect the rigidity of the hollow spline shaft 4 at the flat keyway 40;

[0053] For this, as Figure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com