Convective dryer for biodegradable plastic granules

A technology of biodegradable plastics and convective dryers, applied in drying chambers/containers, drying solid materials, drying gas arrangements, etc., can solve the problem of reducing the drying quality of dryers, reducing the purity of biodegradable plastic particles, and pollution of biodegradable plastic particles, etc. Problems, to reduce the probability of bonding dust and impurities, reduce the content of dust and impurities, improve the effect of intelligence and automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

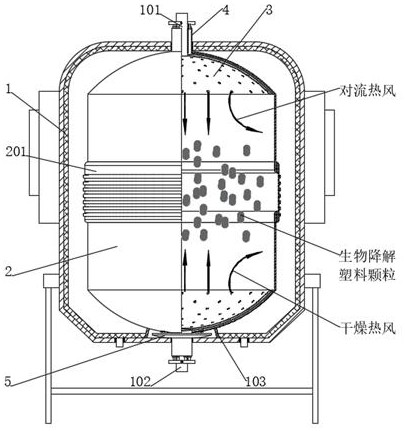

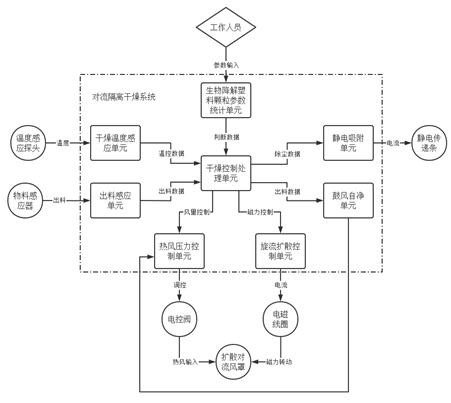

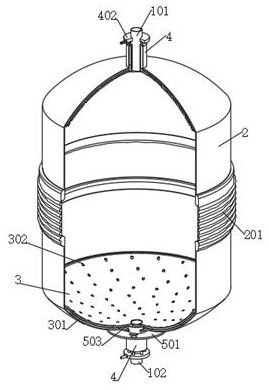

[0045] see Figure 1-11 , a convective dryer for biodegradable plastic particles, comprising a convective dryer body 1, a dust suction diffusion drying bag 2 is fixedly installed in the convection dryer body 1, and the upper and lower inner walls of the dust suction diffusion drying bag 2 are rotatably connected with diffusion The convection hood 3 and the diffusion convection hood 3 are rotatably connected to the end of the dust suction diffusion drying bag 2 with a hot air transmission hollow ring 4 connected to it, and the end of the hot air transmission hollow ring 4 is far away from the diffusion convection hood 3 and extends to the convection dryer On the outer side of the main body 1, the outer end of the hot air transmission hollow ring 4 on the lower side is connected with a magnetic swirl assembly 5 matched with the diffusion and convection wind cover 3, and the end of the diffusion and convection wind cover 3 close to the dust suction diffusion drying bag 2 is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com