High-end PMOS power tube driving circuit

A MOS tube and drive circuit technology, applied in the field of high-end PMOS power tube drive circuits, can solve the problems of difficult integration, power tube breakdown, and complex gate-source voltage clamping circuits of power tubes, so as to improve circuit integration and reduce conduction. The effect of reducing the transmission loss, reducing the cost of use and the area of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

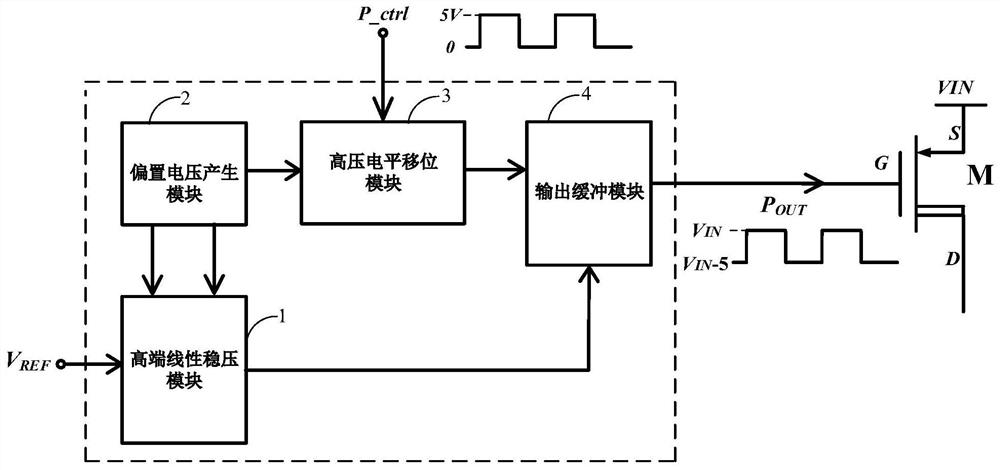

[0079] See figure 1 , figure 1 Is a block diagram of a high-end PMOS power transistor drive circuit according to an embodiment of the present invention, as shown in FIG high PMOS power transistor drive circuit of this embodiment includes: a high linear voltage regulator, the bias voltage generating module 2 , high voltage level shifting module 3 and the output buffer module 4. Wherein the output of the linear regulator-end module 1 is connected to the input of output buffer module 4, the bias voltage generator 2 is connected to the output of the module-end linear regulator module input terminal 1 and the high voltage level shift the input module 3, respectively, input terminal, a high voltage level shift module 3 is connected to the output terminal of output buffer module 4, the output terminal of the output buffer module of P 4 OUT End connected to the gate of the PMOS power transistor M.

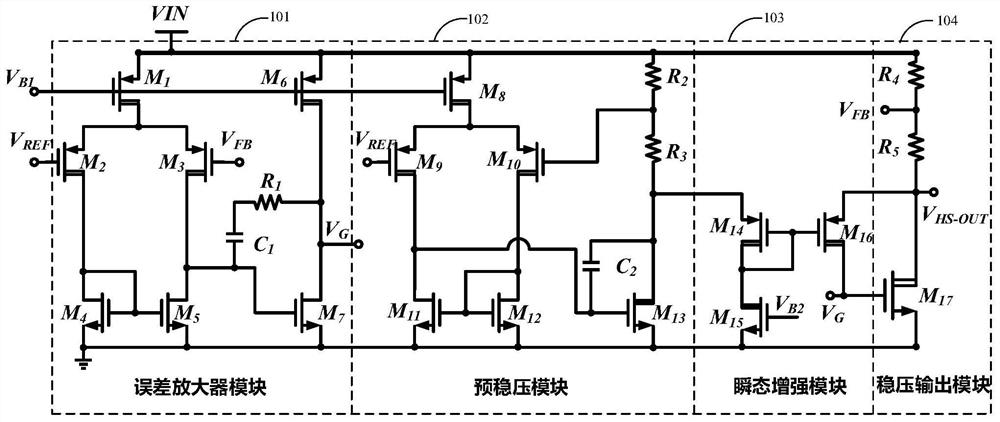

[0080] In particular, high linear regulator module 1 according to the reference voltage in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com