Universal cold plate for airborne punch-through liquid cooling module

A liquid-cooled channel and liquid-cooled technology, which is applied in the direction of modification through conduction heat transfer, cooling/ventilation/heating modification, electrical components, etc., can solve problems such as difficulties in cold plate design and flow resistance matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

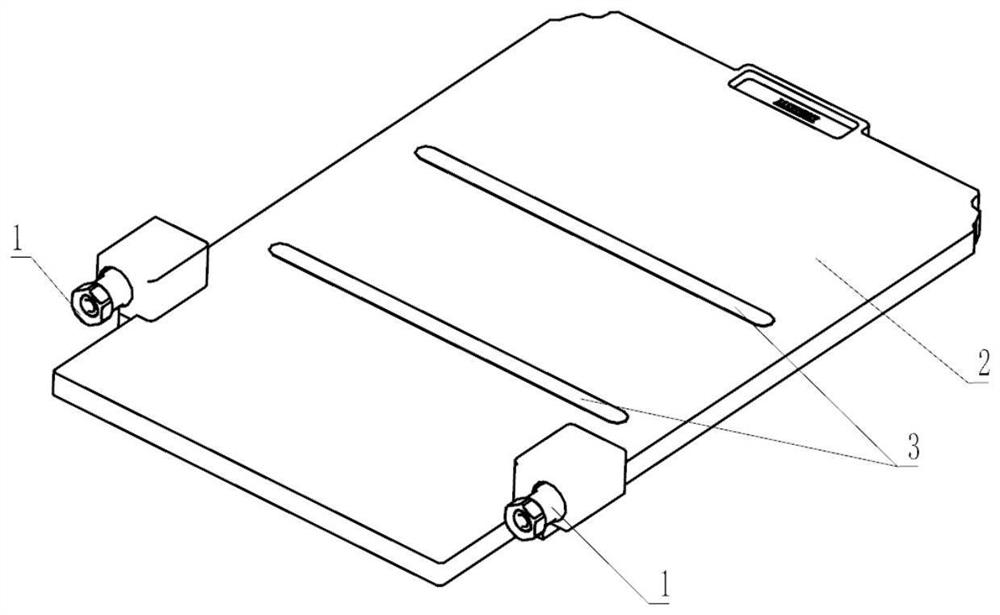

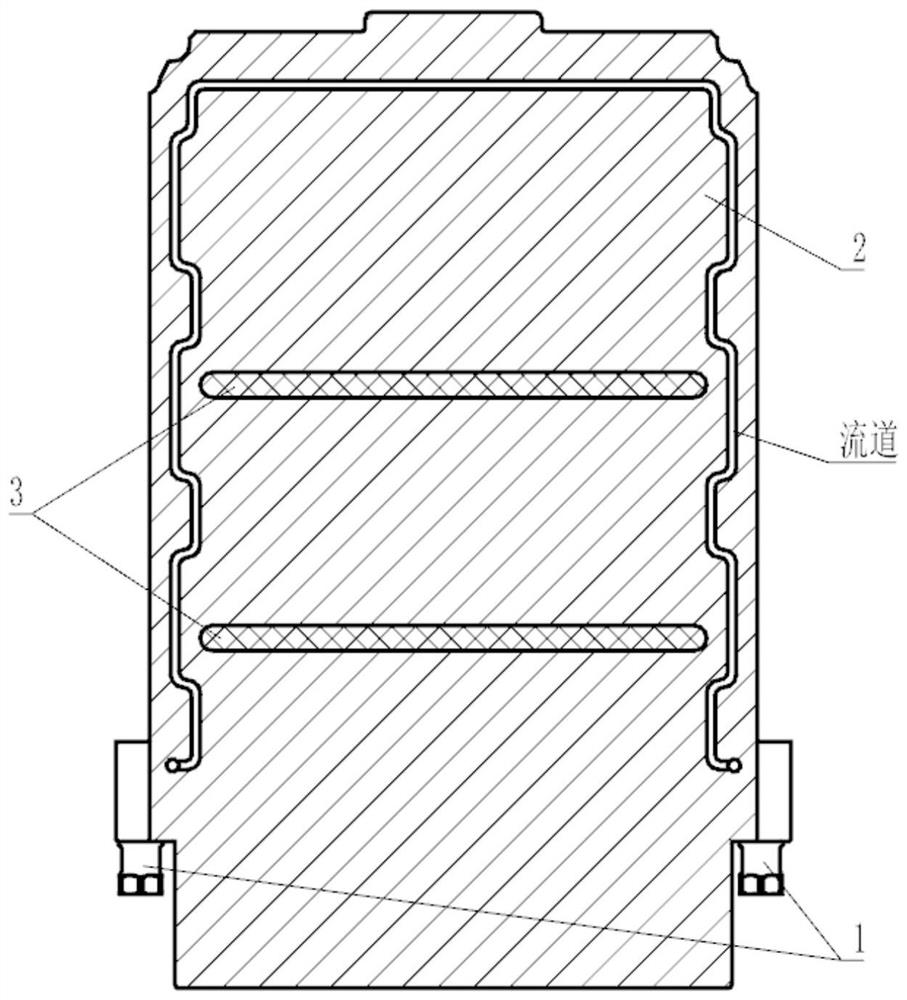

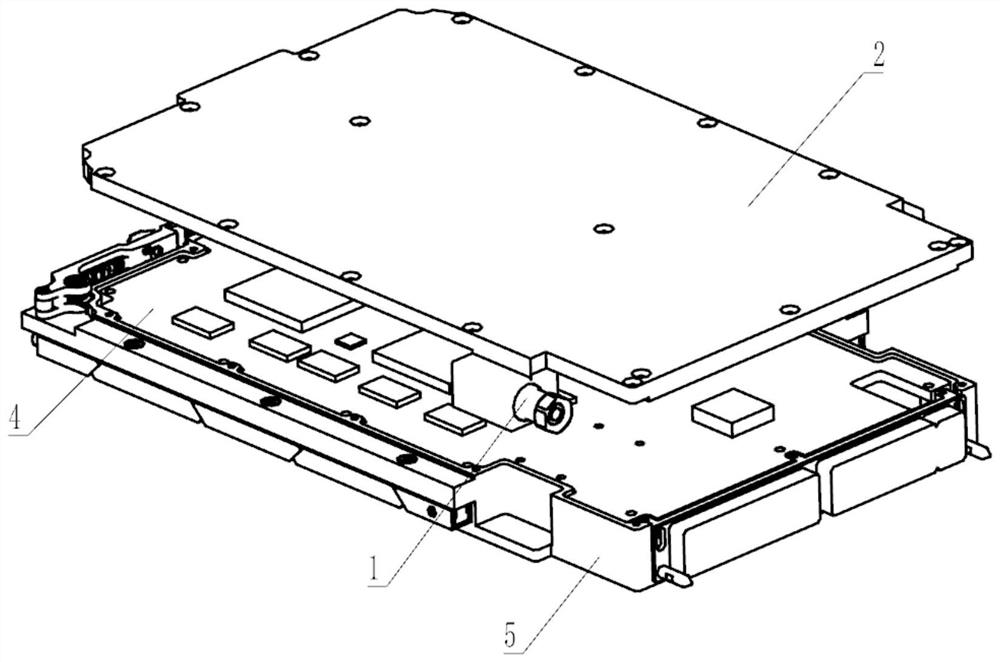

[0015] refer to Figure 1-Figure 3 , in the embodiment described below, an airborne pass-through liquid cooling module universal cold plate, including: a pass-through liquid-cooled module box body 5 integrated with a liquid-cooled cold plate on the plug-in, fixed on the pass-through liquid-cooled module box The LRM liquid cooling transfer connector 1 on the flow channel cover plate of the body 5, and the microchannel cold plate 2 with a liquid cooling flow channel inside. The two ends of the liquid-cooled channel of the micro-channel cold plate 2 are connected through the external fluid LRM liquid-cooled transfer connector 1 to form a closed loop of the internal fluid liquid-cooled channel in which the liquid working fluid flows inside the micro-channel cold plate 2, and then through the LRM liquid-cooled The transfer connector 1 is connected to the liquid cooling circulation system of the on-board liquid cooling equipment; the flow of fluid in the arc-shaped flow channel form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com