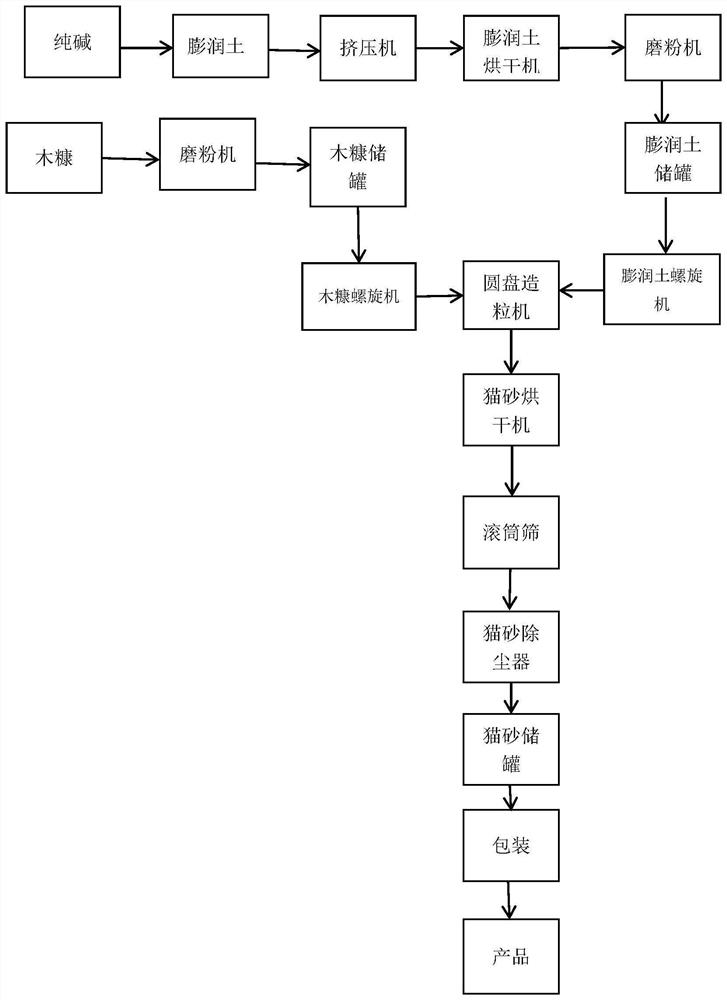

Production process of bentonite-sawdust cat litter

A production process, bentonite technology, applied in the field of bentonite-wood chaff cat litter production process, can solve the problems of poor cleaning, looseness, and strong taste, and achieve the effect of good product quality, no loose agglomeration, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Add soda ash according to 2% of the weight of bentonite;

[0028] 2. After adding soda ash, the bentonite is extruded and sodiumized by an extruder;

[0029] 3. After sodiumization, the bentonite enters the bentonite dryer for drying;

[0030] 4. After drying, the bentonite enters the pulverizer to grind to a particle size of 200 mesh, and the bentonite powder after grinding is sent to the bentonite storage tank;

[0031] 5. The wood chaff is ground to 40 mesh by the mill, and the ground wood chaff is transported to the wood chaff storage tank;

[0032] 6. The bentonite powder obtained in step 4 and the wood bran powder obtained in step 5 are transported into the disc granulator through conveying screws respectively. The bentonite powder and the wood bran powder screw are respectively installed with frequency converters and added quantitatively in proportion. The weight ratio is bentonite :wood bran=97:3;

[0033] 7. The cat litter obtained after granulation enter...

Embodiment 2

[0038] 1. Add soda ash according to 2.5% of the weight of bentonite;

[0039] 2. After adding soda ash, the bentonite is extruded and sodiumized by an extruder;

[0040] 3. After sodiumization, the bentonite enters the bentonite dryer for drying;

[0041] 4. After drying, the bentonite enters the pulverizer to grind to a particle size of 200 mesh, and the bentonite powder after grinding is sent to the bentonite storage tank;

[0042] 5. The wood chaff is ground to 70 mesh by the mill, and the ground wood chaff is transported to the wood chaff storage tank;

[0043] 6. The bentonite powder obtained in step 4 and the wood bran powder obtained in step 5 are transported into the disc granulator through conveying screws respectively. The bentonite powder and the wood bran powder screw are respectively installed with frequency converters and added quantitatively in proportion. The weight ratio is bentonite : wood bran=94:6;

[0044] 7. The cat litter obtained after granulation en...

Embodiment 3

[0049] 1. Add soda ash according to 3% of the weight of bentonite;

[0050] 2. After adding soda ash, the bentonite is extruded and sodiumized by an extruder;

[0051] 3. After sodiumization, the bentonite enters the bentonite dryer for drying;

[0052] 4. After drying, the bentonite enters the pulverizer to grind to a particle size of 200 mesh, and the bentonite powder after grinding is sent to the bentonite storage tank;

[0053] 5. The wood chaff is ground to 100 mesh by the mill, and the ground wood chaff is transported to the wood chaff storage tank;

[0054] 6. The bentonite powder obtained in step 4 and the wood bran powder obtained in step 5 are transported into the disc granulator through conveying screws respectively. The bentonite powder and the wood bran powder screw are respectively installed with frequency converters and added quantitatively in proportion. The weight ratio is bentonite :wood bran=91:9;

[0055] 7. The cat litter obtained after granulation ente...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com