Method for preparing geopolymer by using chromium slag

A technology of geopolymers and chromium slag, which is applied in the field of preparing geopolymers from chromium slag, which can solve the problems of high energy consumption and high cost of recycling, and achieve the effect of increasing the added value of resources and facilitating production and deployment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

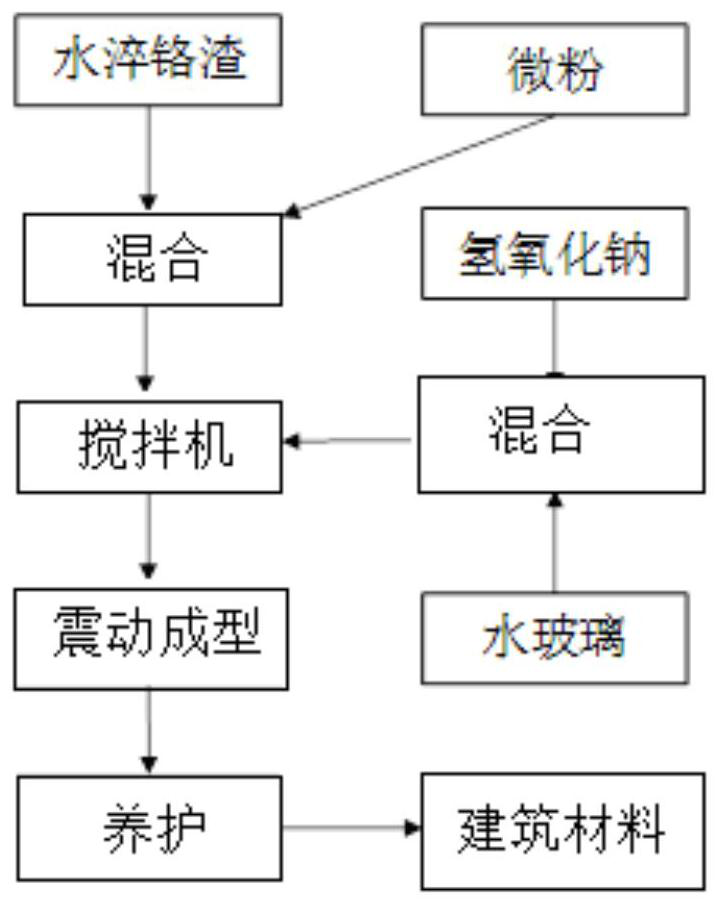

Method used

Image

Examples

Embodiment 1

[0028] The present embodiment provides a kind of method utilizing chromium slag to prepare geopolymer, comprises the following steps:

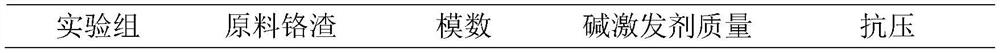

[0029] (1) Preparation of alkali activator: take water glass with different modulus and dissolve it in a beaker, weigh sodium hydroxide (content 99%), pour sodium hydroxide into the water glass solution, and use a glass rod to continuously stir , until all the sodium hydroxide is dissolved in the water glass solution. After stirring, seal it with plastic wrap and wait until the solution cools down before using it. The modulus selected for the experiment of this embodiment is 1-1.8.

[0030] (2) Pretreatment of chromium slag: pulverize the water-quenched chromium slag, then pass the crushed chromium slag through a 100-mesh sieve, and re-grind the sieve through a pulverizer until all pass through a 100-mesh sieve.

[0031] (3) Preparation of geopolymers from chromium slag raw materials: Mix the pulverized chromium slag with a certain amount of...

Embodiment 2

[0038] The present embodiment provides a kind of method utilizing chromium slag to prepare geopolymer, comprises the following steps:

[0039] (1) Preparation of alkali activator: take water glass with different modulus and dissolve it in a beaker, weigh sodium hydroxide (content 99%), pour sodium hydroxide into the water glass solution, and use a glass rod to continuously stir , until all the sodium hydroxide is dissolved in the water glass solution. After stirring, seal it with plastic wrap and wait until the solution cools down before using it. The experiment of this embodiment selects the modulus as 1.4.

[0040] (2) Pretreatment of chromium slag: crush the water-quenched chromium slag, and then pass the crushed chromium slag through 100-mesh and 200-mesh sieves.

[0041] (3) Preparation of geopolymers from chromium slag raw materials: Mix the pulverized chromium slag with micropowder and stir evenly, then add alkali activator, stir well, pour into mortar mold and vibrat...

Embodiment 3

[0048] The present embodiment provides a kind of method utilizing chromium slag to prepare geopolymer, comprises the following steps:

[0049] (1) Preparation of alkali activator: take different amounts of water glass and dissolve it into a beaker, take by weighing sodium hydroxide (content 99%), pour sodium hydroxide into the water glass solution, use a glass rod to continuously stir, Until the sodium hydroxide is completely dissolved in the water glass solution. During this process, it should be noted that the sodium hydroxide dissolves in the water glass and releases a large amount of heat, which may cause a certain amount of water to evaporate, so after stirring, seal it with plastic wrap, and wait until the solution is cooled before use.

[0050](2) Pretreatment of chromium slag: pulverize the water-quenched chromium slag, then pass the crushed chromium slag through a 100-mesh sieve, and re-grind the sieve through a pulverizer until all pass through a 100-mesh sieve.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com