Single crystal graphene and preparation method thereof

A single crystal graphene, graphene technology, applied in the field of graphene, can solve the problems of graphene performance quality decline, slow growth rate, etc., to achieve the effect of consistent orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

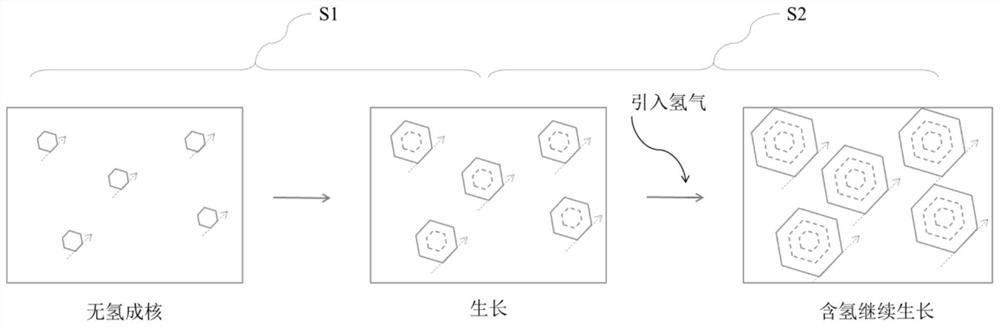

[0019] refer to figure 1 , one embodiment of the present invention provides a method for preparing single-crystal graphene, comprising preparing single-crystal graphene by a chemical vapor deposition process; wherein, the chemical vapor deposition process includes the following steps:

[0020] S1: Formation of aligned graphene nuclei on a substrate in a system that does not contain a reducing gas; and

[0021] S2: Continue to grow under the action of reducing gas to form single crystal graphene.

[0022] In the present invention, "single crystal graphene" means a single layer of graphene without grain boundaries.

[0023] In the present invention, in step S1, nucleation is performed on the substrate by chemical vapor deposition; wherein, "nucleation" refers to the formation of small islands of graphene from the cracked carbon species after the introduction of the carbon source.

[0024] In one embodiment, the reducing gas is hydrogen.

[0025] In one embodiment, hydrogen ga...

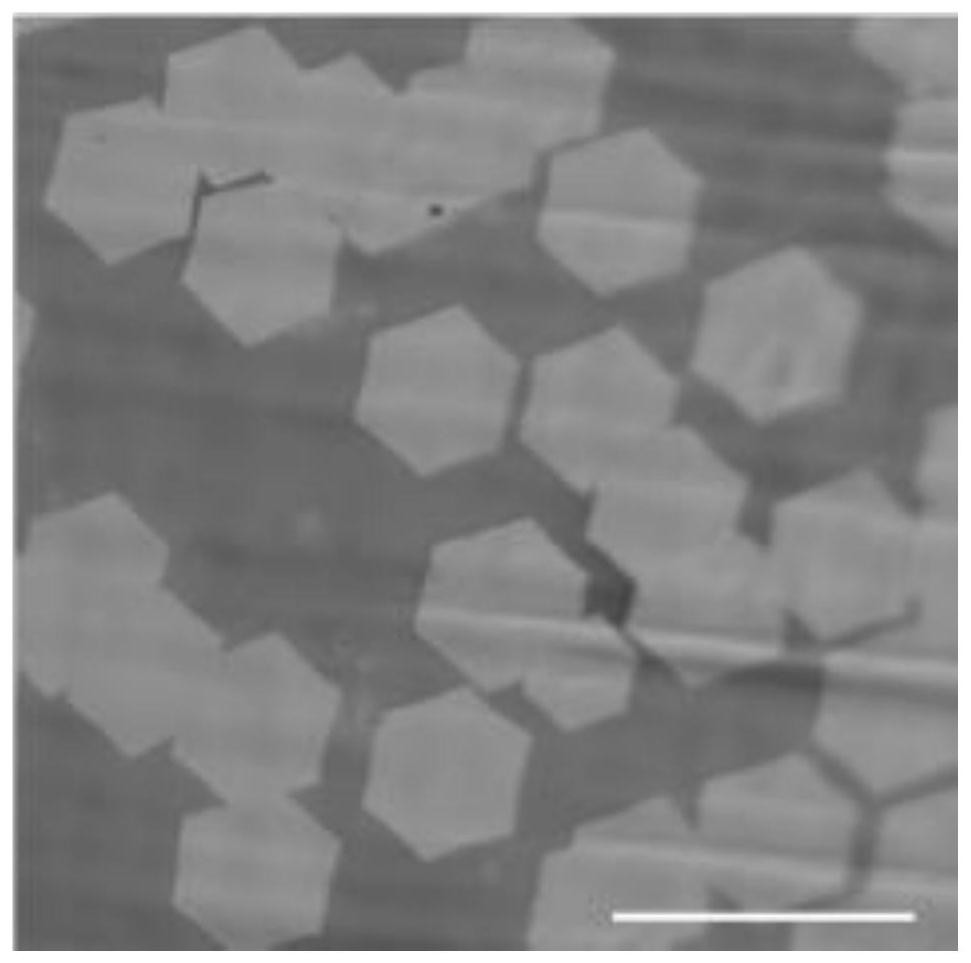

Embodiment 1

[0079] The preparation of single crystal graphene includes the pretreatment process of the substrate and the growth process of graphene, and the two processes are carried out in the same reactor, that is, the substrate does not move during the preparation process.

[0080] Substrate pretreatment

[0081] 1) Place copper foil (produced by Alfa Aesar, with a purity of 99.8%, and a thickness of 25 μm) in a phosphoric acid glycol solution for electrochemical polishing. The mass concentration of phosphoric acid is 85%, and the volume ratio of phosphoric acid to ethylene glycol is 3:1 , the polishing current density is maintained at about 100A / m 2 , the polishing time is about 30min; the polished copper foil is rinsed with deionized water and blown dry with nitrogen.

[0082] 2) Put the above-mentioned polished copper foil in a casing with magnetic control, and put the casing in a large quartz tube of a tube furnace, and raise the temperature to an annealing temperature of 1020° C....

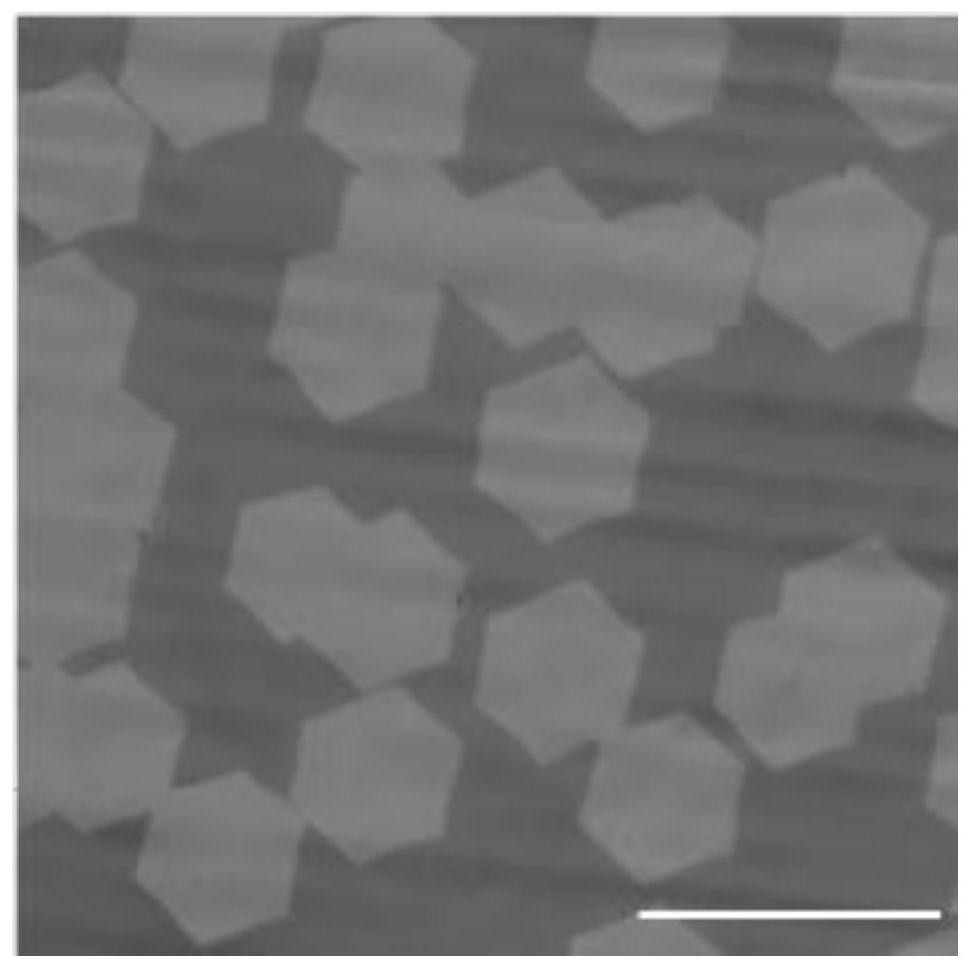

Embodiment 2

[0088] The raw materials and process conditions used in this embodiment are basically the same as in Example 1, the difference is that in step S1, the argon flow is 1500 sccm, the methane flow is 0.5 sccm, and the growth time (reaction time) is 30s; in step S2, The flow rate of argon gas is 1000 sccm, the flow rate of hydrogen gas is 500 sccm, the flow rate of methane gas is 0.5 sccm, and the growth time is 20 min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com