Fabric flattening and tentering treatment device

A processing device and flattening technology, which is applied in the direction of fabric elongation, heating device, fabric surface trimming, etc., can solve the problems of easy wrinkling of textiles, affect the aesthetics of textiles, reduce the quality of textiles, etc. Processing effect, improving cutting and trimming quality, and shortening production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

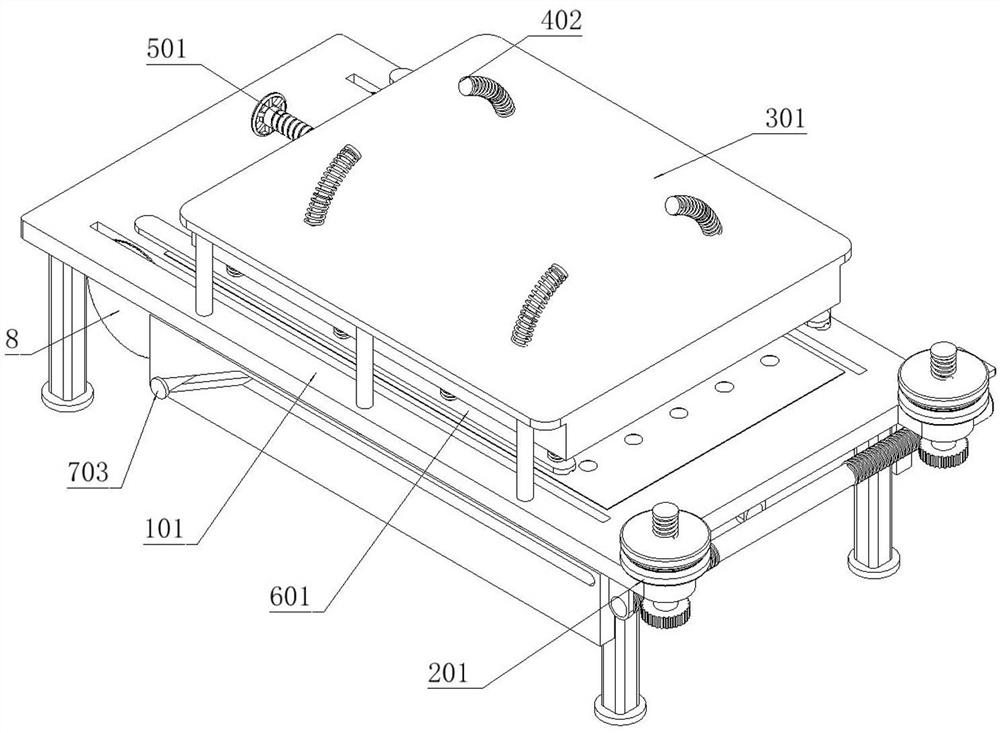

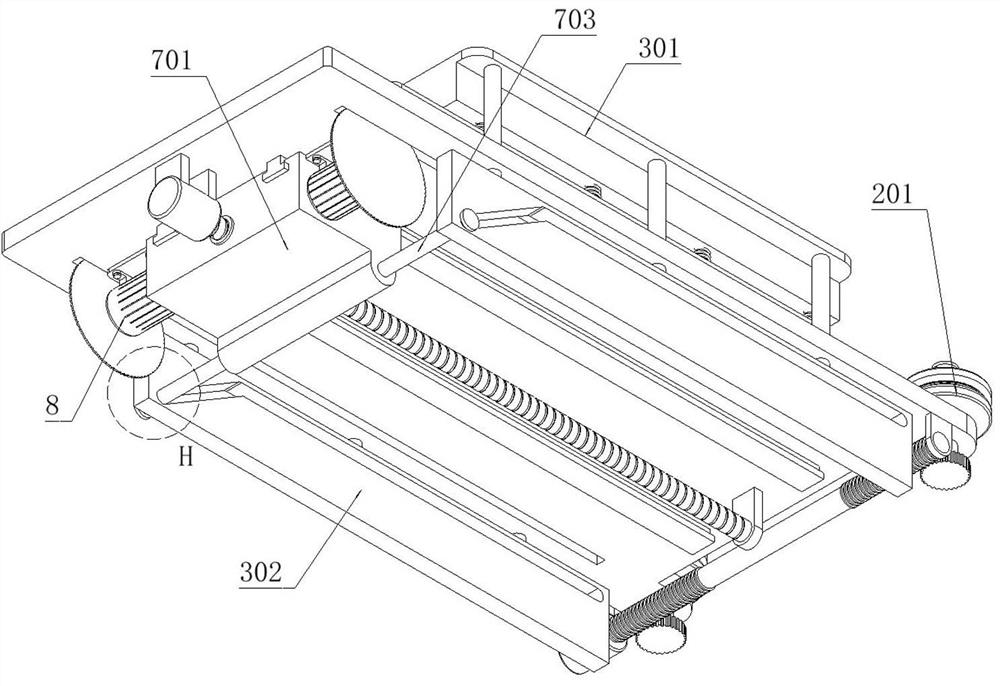

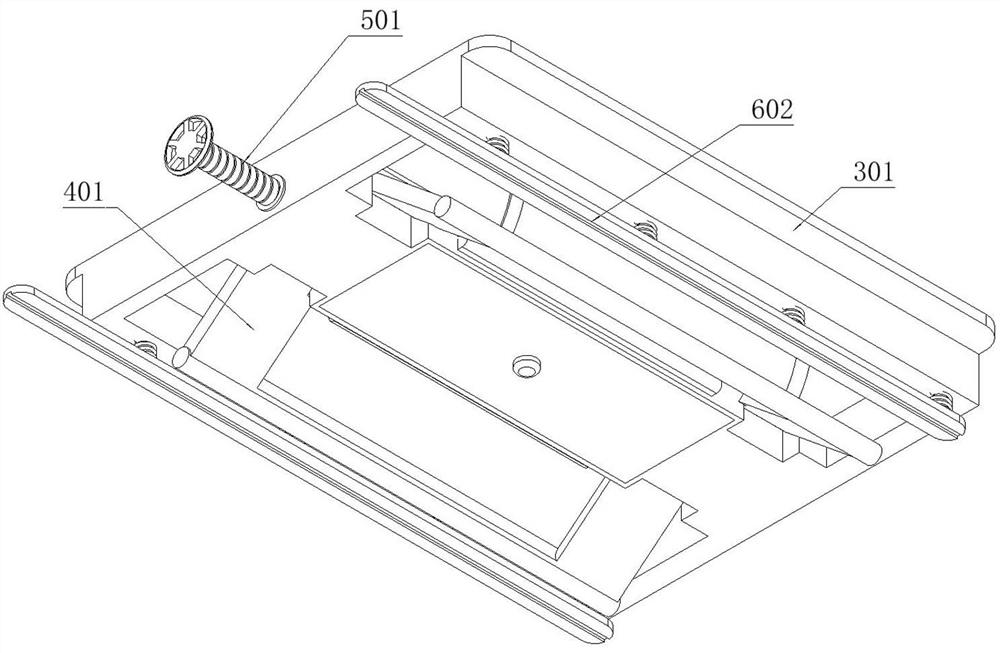

[0084] as attached figure 1 to attach Figure 17 Shown:

[0085] The present invention provides a fabric tentering treatment device, comprising a support device 1;

[0086] The supporting device 1 is fixed with a weft yarn positioning device 2; the supporting device 1 is slidably connected with a flattening part 3, and two sets of tentering devices 4 are installed on the flattening part 3; a tenter adjusting part 5 is installed inside the flattening part 3; The two sides of the part 3 are slidingly connected with the cutting positioning part 6 respectively; the tenter adjusting part 5 includes: the tenter adjusting screw rod 501, which is threaded on the flat mounting plate 301; the pushing block 502, the pushing block 502 There is a "T"-shaped slider on the top; the top of the push block 502 is slidably connected to the adjustment installation groove 304 through the slider, and the rear side of the push block 502 is rotatably connected to the front end of the tenter adjustm...

Embodiment 2

[0091] On the basis of the first embodiment, this embodiment provides another structural form of the linkage shaft 703, which solves the problem of the long-term friction between the linkage shaft 703 and the linkage groove 303 on the linkage groove block 302 to generate a large amount of heat. For problems that affect the service life, the linkage trimming part 7 includes: a driving slider 701, which is slidably connected to the bottom of the installation base plate 101; a threaded hole is provided on the driving slider 701; both sides of the driving slider 701 are respectively fixed by brackets Connected with electric cutter 8; electric screw mandrel 702, electric screw mandrel 702 is installed on the bottom of installation base plate 101 through bracket, and drive slider 701 is screwed on electric screw mandrel 702; Linkage shaft rod 703, linkage shaft rod 703 is fixedly connected At the bottom of the driving slider 701, and the two sides of the linkage shaft 703 are sliding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com