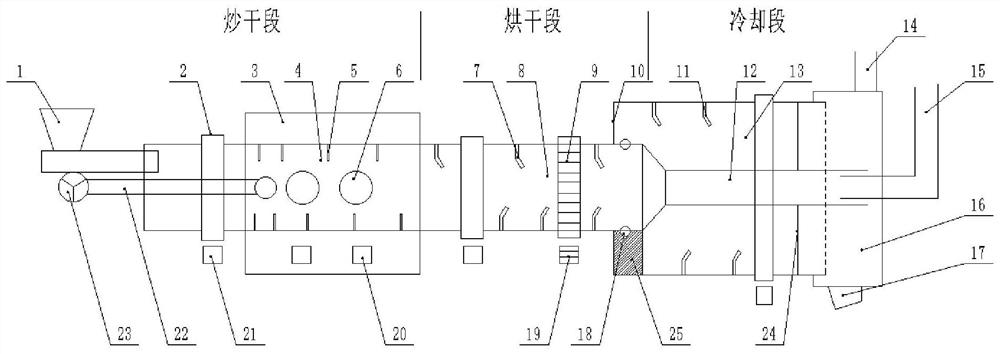

Frying, drying and cooling three-section type dryer suitable for high-moisture materials

A three-stage, high-moisture technology, applied in dryers, non-progressive dryers, drying, etc., can solve problems such as increased equipment investment, long treatment cycle, and inability to operate in winter to meet environmental protection and fire protection requirements , reduce energy consumption and operating costs, and have good drying effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to enable those skilled in the art to better understand the technical solutions of the present disclosure, the present disclosure will be described in detail below in conjunction with the accompanying drawings and specific embodiments. Embodiments of the present disclosure will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but are not intended to limit the present disclosure.

[0029] "First", "second" and similar words used in the present disclosure do not indicate any order, quantity or importance, but are only used to distinguish different parts. Words like "comprising" or "comprising" mean that the elements preceding the word cover the elements listed after the word, and do not exclude the possibility of also covering other elements. "Up", "Down", "Left", "Right" and so on are only used to indicate the relative positional relationship. When the absolute position of the described object changes, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com