25G DFB laser high-frequency interconnection method

A laser and high-frequency technology, which is applied in the field of optical fiber communication, can solve the problems of high-frequency interconnection return loss, eye diagram degradation, etc., and achieve the effect of reducing high-frequency return loss and optimizing design parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

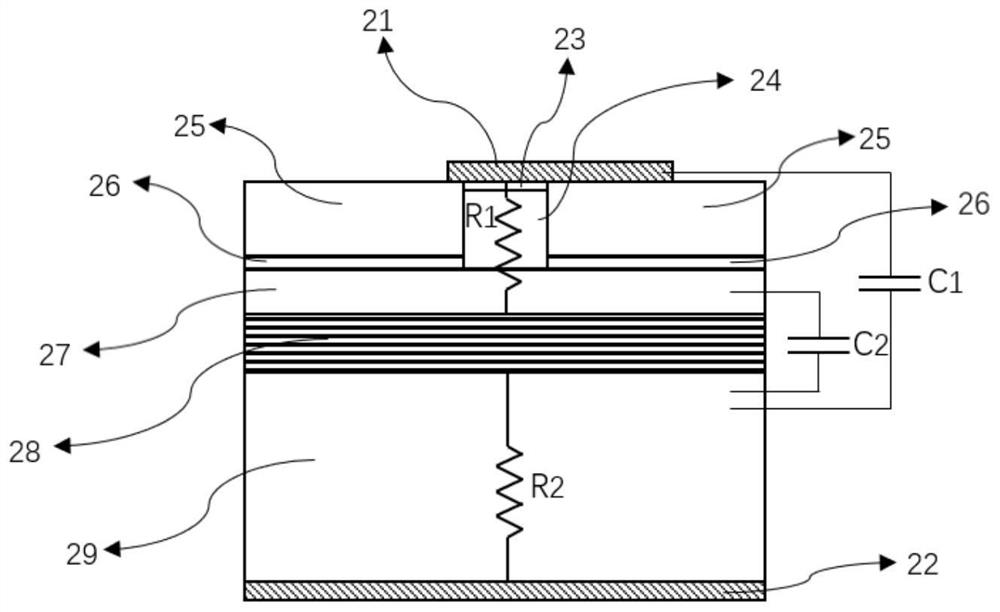

[0026] The technical solution of the present invention will be further described below with the case of TO 56 in conjunction with the accompanying drawings, and this technical solution is also applicable to TO 38.

[0027] Considering the characteristics of the material used in the 25G DFB TO tube base and the cost of the mold opening of the TO tube base, the 25G DFB TO tube base used in the present invention still uses the more typical 25G TO DFB TO tube base used in the industry today .

[0028] The 25G DFB laser high-frequency interconnection method of the present invention comprises the following steps

[0029] 1. Execute one or more designs in steps (1)-(5).

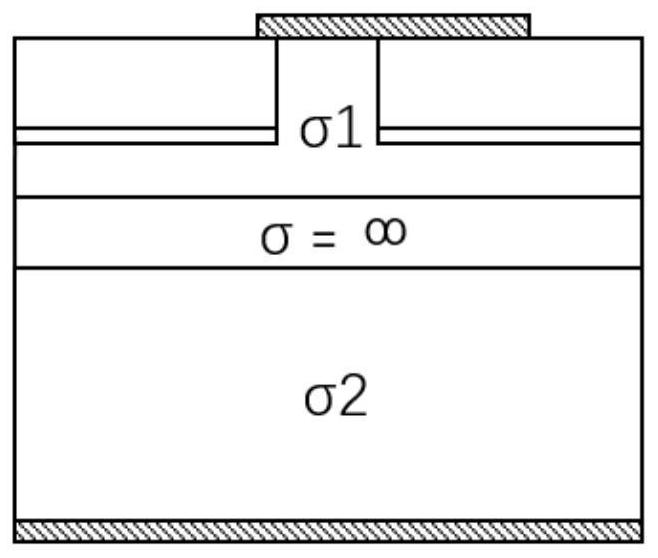

[0030] (1) Design the shape and size of the microstrip line on the ceramic substrate. The ceramic substrate microstrip line includes a left microstrip line and a right microstrip line. The left microstrip line and the right microstrip line are asymmetrical in design, and the gap between the left microstrip line an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com