MOLTEN Zn-Al-Mg-PLATED STEEL SHEET AND METHOD FOR PRODUCING SAME

A manufacturing method and hot-dip galvanizing technology, applied in hot-dip galvanizing process, manufacturing tools, heat treatment furnace, etc., can solve problems such as processability deterioration and achieve high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0066] One embodiment of the present invention will be described below.

[0067] 〔experiment method〕

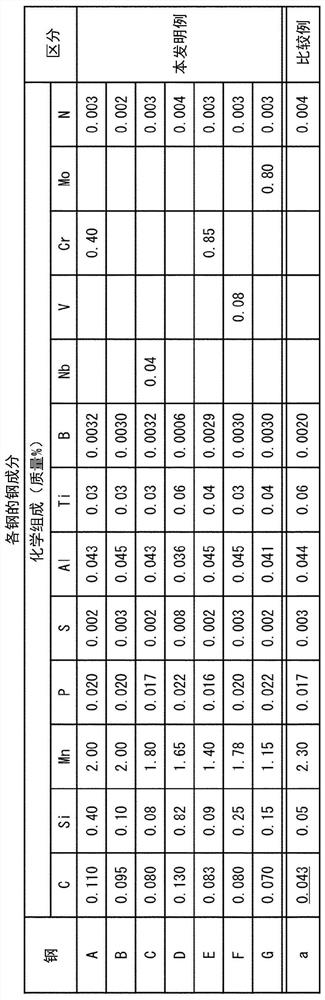

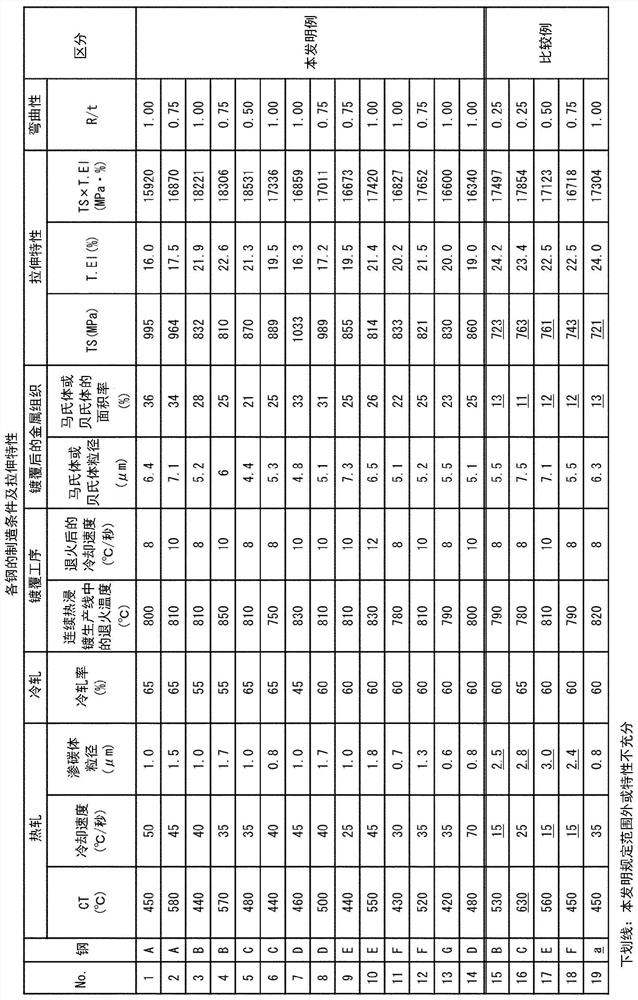

[0068] will have figure 1 The slab with the chemical composition shown in is hot-rolled at a heating temperature of 1250°C, a finish rolling temperature of 880°C, an average cooling rate from finish rolling to coiling of 15-70°C / sec, and a coiling temperature of 420-630°C. A hot-rolled steel sheet having a thickness of 1.8 to 2.8 mm was obtained. After the hot-rolled steel plate is pickled, it is cold-rolled at a rolling rate of 45 to 65% to make a plated original plate (steel base material) with a plate thickness of 1.0 mm, which is passed through the continuous hot-dipping production line. Annealing is performed at various temperatures ranging from 750°C to 850°C in a hydrogen-nitrogen mixed gas atmosphere, and cooled to approximately 420°C at a cooling rate of 8°C to 12°C / sec.

[0069] Afterwards, in a state where the surface of the steel sheet is not in contact with th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com