Pencil lead, wood substitute, pencil and preparation method thereof

A technology for substitutes and refills, applied in the direction of pencil refills, non-active pencils, printing, etc., can solve the problem of pigment dispersion in refills and low interface bonding strength, lack of adhesion and protection of refills, and sharpening of sharpened pencils Torque and other issues to achieve the effect of ensuring interface compatibility, good environmental protection characteristics, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

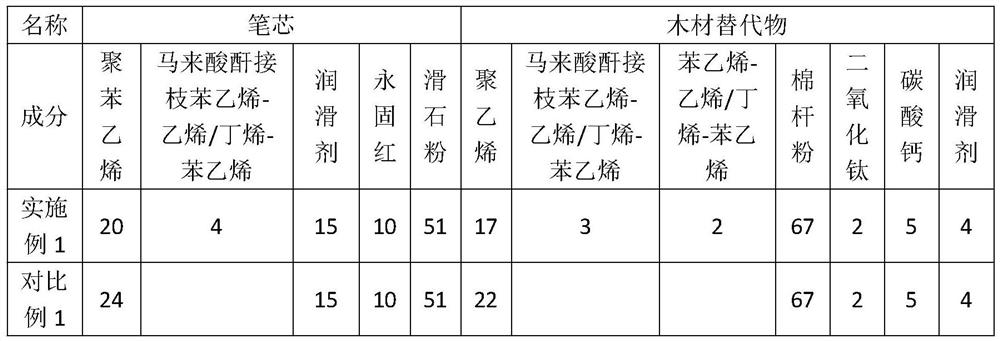

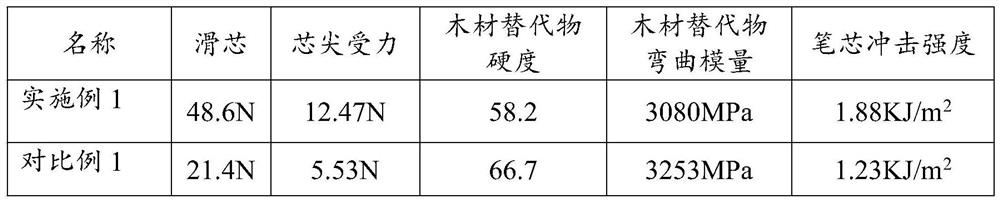

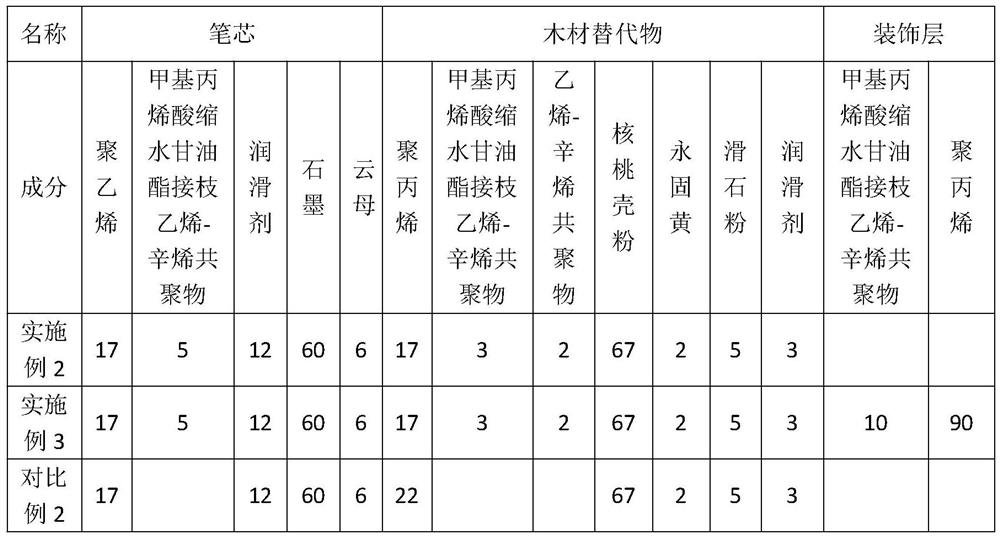

Examples

Embodiment Construction

[0061] It should be noted that the following detailed description is exemplary and intended to provide further explanation of the present invention. Unless defined otherwise, all technical and scientific terms used herein have the same meaning as commonly understood by one of ordinary skill in the art to which this invention belongs.

[0062] In the first typical implementation of the present invention, a kind of pen core is proposed, and the pen core comprises at least one first polymer, and the first polymer includes:

[0063] Copolymers of lower olefins and higher olefins, styrene block copolymers, copolymers of ethylene and unsaturated carboxylic acids, copolymers of ethylene and unsaturated carboxylic acid esters, copolymers of ethylene and saturated vinyl carboxylates, or Several;

[0064] And, functional monomer grafts;

[0065] The functional monomer graft is one or more of unsaturated carboxylic acid, unsaturated diacid anhydride, unsaturated carboxylic acid alkyl e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com