Economical and environment-friendly goaf filling method and device

A filling device and goaf technology, which can be used in fillings, safety devices, mining equipment, etc., can solve the problem of high construction cost, and achieve the effects of reducing filling costs, saving funds, and protecting resources and the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] An economical and environment-friendly goaf filling method, comprising:

[0038] S1. Conveying cement

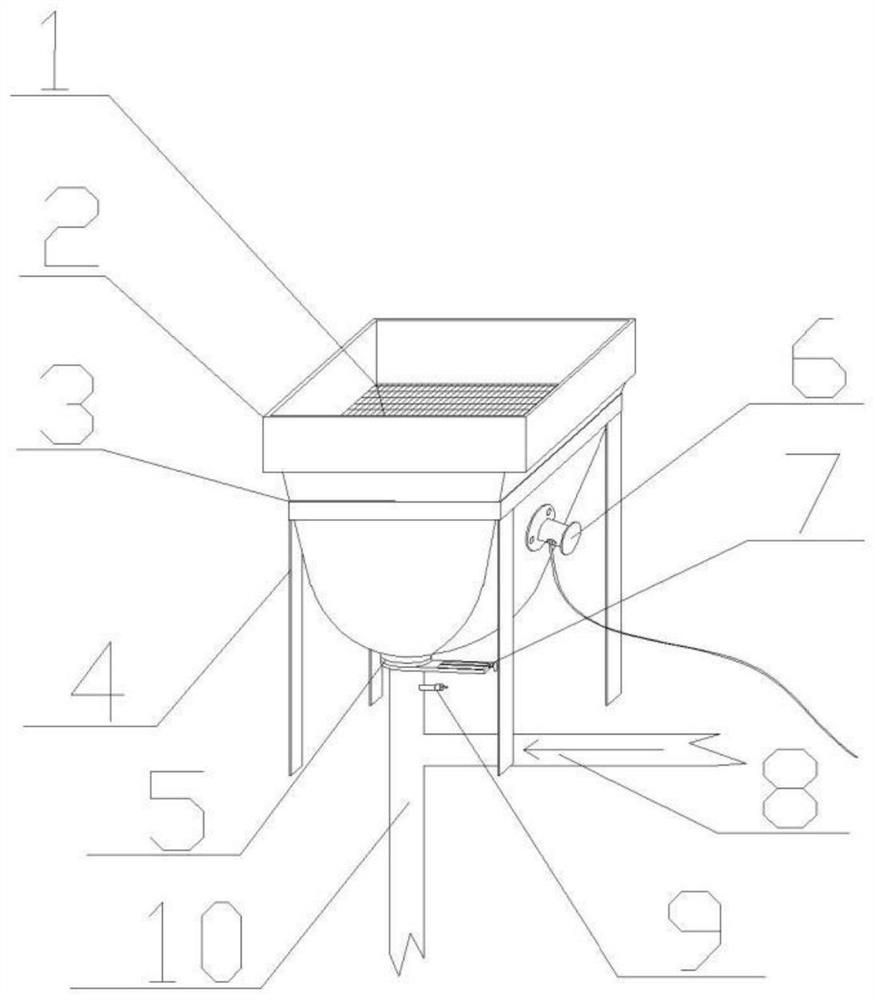

[0039] Cement enters the gob by pumping through the slurry inlet pipe 8;

[0040] S2. Convey geopolymer

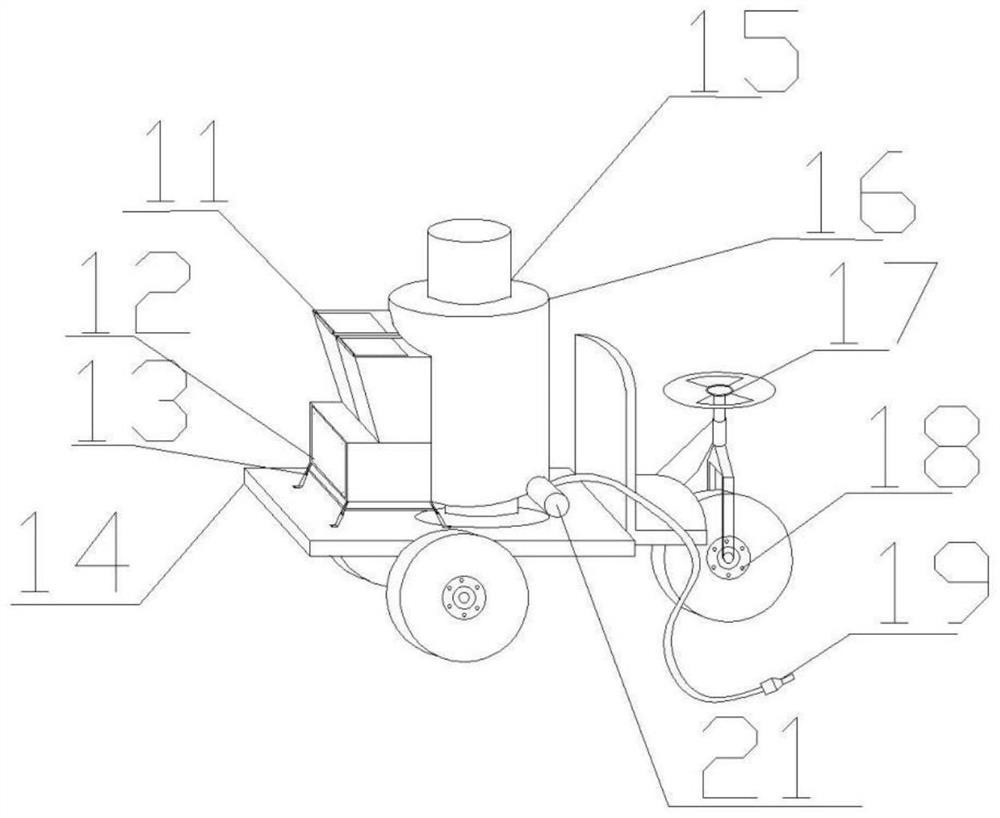

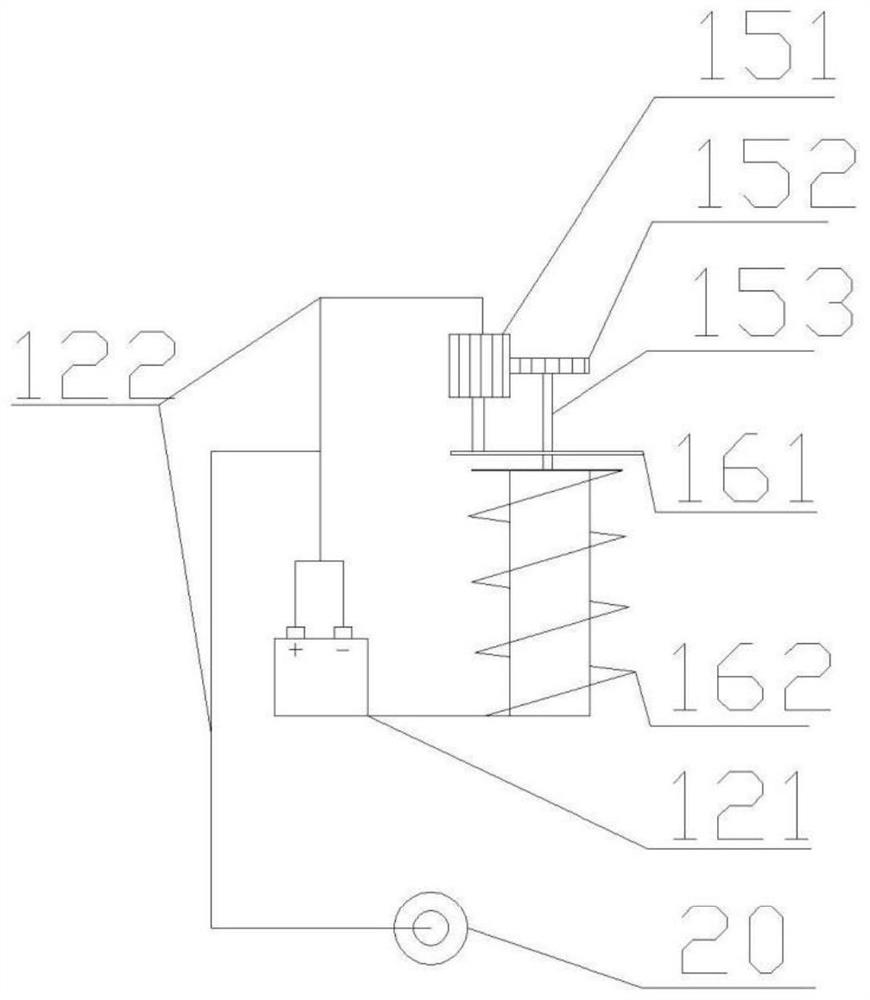

[0041] After conveying cement for 25 minutes, start to convey the geopolymer through the filling device, and the conveyed geopolymer enters the goaf through the feed port 2, and at the same time, the slurry inlet pipe 8 continues to pump cement at a pumping speed of 100L / min, conveying the geopolymer The polymer enters the hopper 3 under the action of the vibrator 6, and the cement with a higher consistency can carry the geopolymer into the goaf. In order to ensure the filling effect, the device stops for 15 minutes every 1 hour. When the filling height is close to the mining area When the roof of the empty area is about 0.5m, stop the injection of geopolymer and cement;

[0042] S3, strengthening the formation

[0043] At the position 0.5m below the roof of t...

Embodiment 2

[0050] The difference with Example 1 is:

[0051] The preparation method of described geopolymer is:

[0052] S21. Select according to the mass fraction: 48 parts of red mud, 7 parts of cement, 2 parts of mineral powder, 2 parts of desulfurized gypsum, 30 parts of fly ash, 2 parts of ceramic particles, 2 parts of zirconia and 4 parts of admixture.

Embodiment 3

[0054] The difference with embodiment 2 is:

[0055] S21. Select according to the mass fraction: 50 parts of red mud, 8 parts of cement, 3 parts of mineral powder, 3 parts of desulfurized gypsum, 40 parts of fly ash, 1 part of ceramic particles, 1 part of zirconia and 3 parts of admixture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com