Optical film and preparation method thereof and flexible cover plate

An optical film and substrate film technology, applied in optics, optical components, instruments, etc., can solve the problems of difficult cutting and forming process, non-bending, easy to break, etc., to meet the needs of flexible display devices, good surface hardness , the effect of not easily broken

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10 and comparative example 1~3

[0050] The types of optical films prepared in Examples 1-10 are different, and Comparative Examples 1-3 adopt conventional CPI products (purchased from Kolon Company), and the two sides of CPI products adopt hard coating (hard coating), thinned glass (thickness 70um, purchased from Short Corporation)

[0051] The compositions of the optical film production raw materials in Examples 1 to 10 are shown in Table 1.

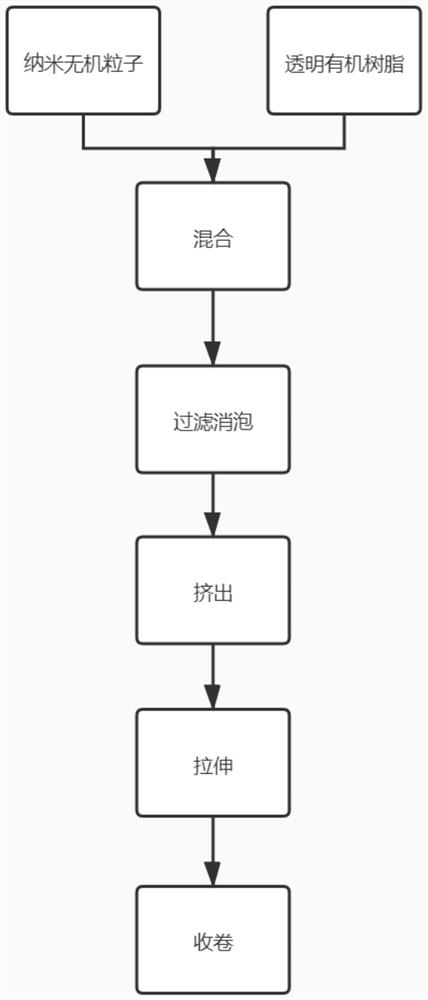

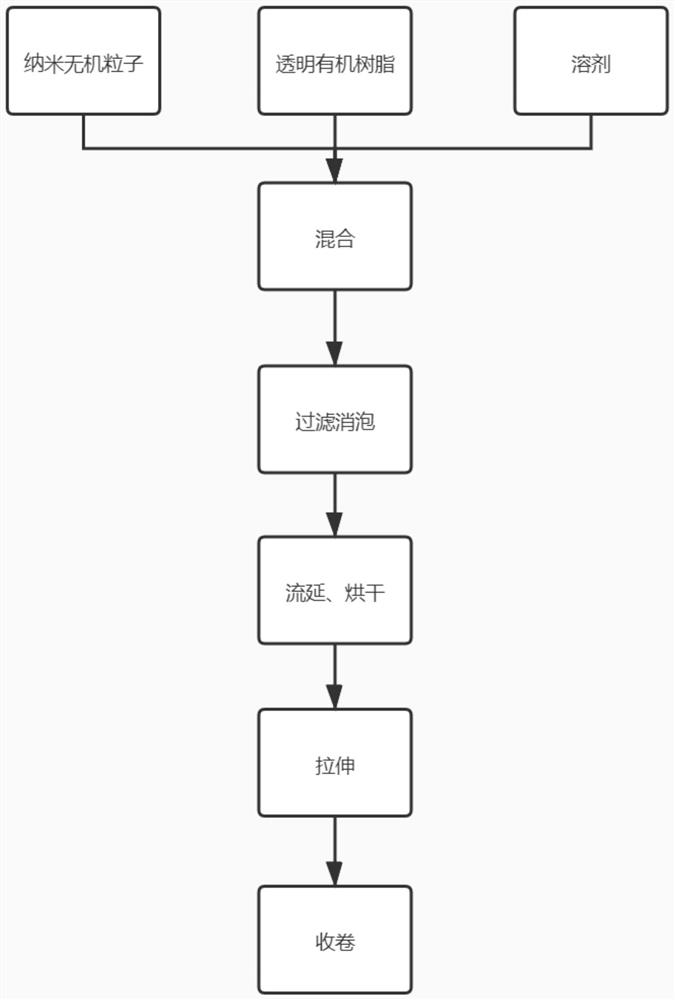

[0052] Embodiments 1 to 5 use the extrusion process to carry out the nano-inorganic particles and the transparent organic resin; specifically, as figure 2 As shown, the first step is to fully mix the inorganic nanoparticles and the transparent organic resin: if it is a low melting point resin, it can be mixed with the inorganic nanoparticles in the molten state; the mixing process can be combined with the grinding process to ensure that the nanoparticles are fully dispersed; the nanoparticles and After the resin is mixed, it can be granulated, or it can enter the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com