Modified vinyl acetal resin for laminated glass interlayer film

A technology of vinyl acetal resin and laminated glass, which is applied in the direction of glass/slag layered products, layered products, transportation and packaging, etc. It can solve the problems of slow cooling speed, reduced transparency, poor bonding, etc., and achieve durability Excellent impact strength, good balance, and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0119] (Synthesis of modified vinyl acetal resin)

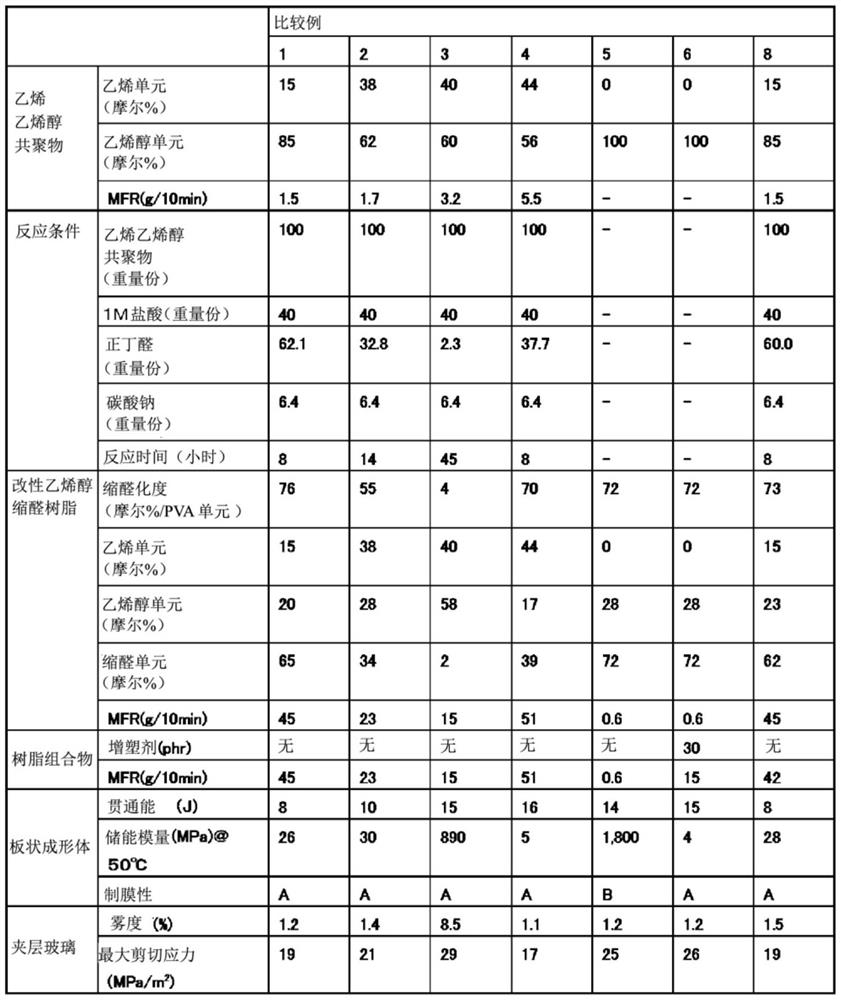

[0120] Disperse 100 parts by weight of an ethylene vinyl alcohol copolymer sheet of 44 mol% ethylene units, saponification degree 99%, MFR 5.5g / 10min, synthesized by the method described in JP 2016-28139, in 315 parts by weight of 1-propylene In the alcohol, the temperature of the solution was raised to 60° C. with stirring, 40 parts by weight of 1M hydrochloric acid was added, and 16.7 parts by weight of n-butyraldehyde was added and dispersed, followed by acetalization reaction while maintaining 60° C. As the reaction progressed, the flakes dissolved to form a homogeneous solution. When the reaction was started for 36 hours, 6.4 parts by weight of sodium bicarbonate was added to stop the reaction. After adding 500 parts by weight of 1-propanol to the reaction liquid to make it uniform, it was added dropwise to 2000 parts by weight of water to deposit a resin. Thereafter, the operation of filtering and washing with water w...

Embodiment 2~6

[0124] Each modified vinyl acetal was obtained in the same manner as in Example 1, except that the ethylene unit, MFR, the addition amount of n-butyraldehyde, and the reaction time of the ethylene vinyl alcohol copolymer used were changed to those shown in Table 1. The resin was melt-kneaded in the same manner as in Example 1 to obtain a melt-kneaded product. Various physical property evaluations were performed using the obtained melt-kneaded product. The results are shown in Table 1.

Embodiment 7

[0126] Each modified vinyl acetal resin was obtained in the same manner as in Example 2, and triethylene glycol-di-2-ethylhexanoic acid was added as a plasticizer to 100 parts by weight of the modified vinyl acetal resin A melt-kneaded product was obtained in the same manner as in Example 1 except that the ester was 8 parts by weight. Various physical property evaluations were performed using the obtained melt-kneaded product. The results are shown in Table 1.

[0127] [Table 1]

[0128]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com