Thermosetting resin composition, coating film formation method, and cured coating film

A resin composition and thermosetting technology, applied in the fields of thermosetting resin composition, coating film formation and cured coating film, can solve problems such as low reactivity and achieve the effect of good curing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

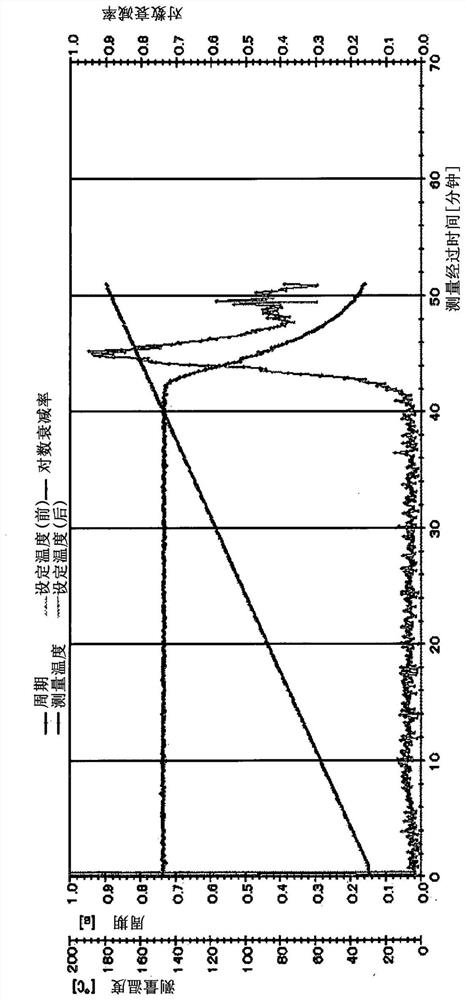

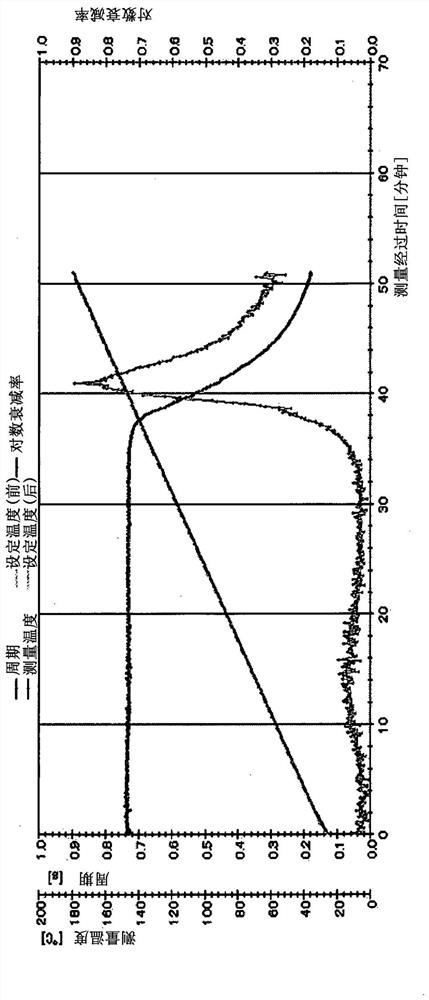

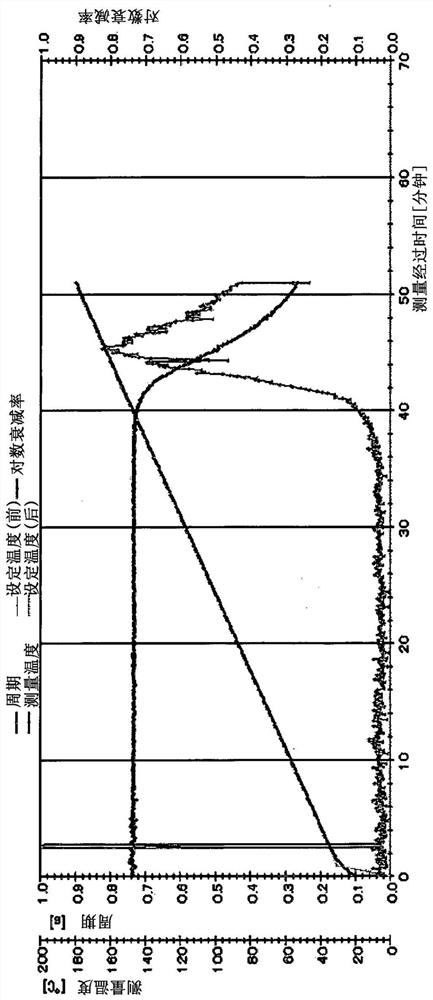

Image

Examples

Embodiment

[0396] Hereinafter, the present invention will be described in more detail based on examples. In addition, this invention is not limited to the following Example. It should be noted that the parts herein represent weight.

Synthetic example 1

[0398] Mix 54 parts of ethylene glycol monoacetoacetate monomethacrylate, 58 parts of n-butyl acrylate, 38 parts of potassium carbonate, 2 parts of 18-crown-6-ether, and 112 parts of tetrahydrofuran, and stir at 50°C for 3 hours . After completion of the reaction, cyclohexane and water were thrown in and washed with water. The organic layer was neutralized with saturated ammonium chloride aqueous solution, washed with water twice, and the obtained organic layer was concentrated under reduced pressure to obtain monomer A.

Synthetic example 2

[0400] 54 parts of ethylene glycol monoacetoacetate monomethacrylate, 43 parts of methyl acrylate, 33 parts of potassium carbonate, 2 parts of 18-crown-6-ether, and 97 parts of tetrahydrofuran were mixed, and stirred at 50° C. for 3 hours. After completion of the reaction, cyclohexane and water were thrown in and washed with water. The organic layer was neutralized with saturated ammonium chloride aqueous solution, washed with water twice, and the obtained organic layer was concentrated under reduced pressure to obtain monomer B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com