Magnesium alloy additive repairing and remanufacturing method

A magnesium alloy, remanufacturing technology, applied in the direction of manufacturing tools, additive processing, metal processing equipment, etc., can solve the problems of poor performance, high dilution rate, poor forming effect, etc., to avoid pores and cracks, simple process flow, The effect of grain refinement improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

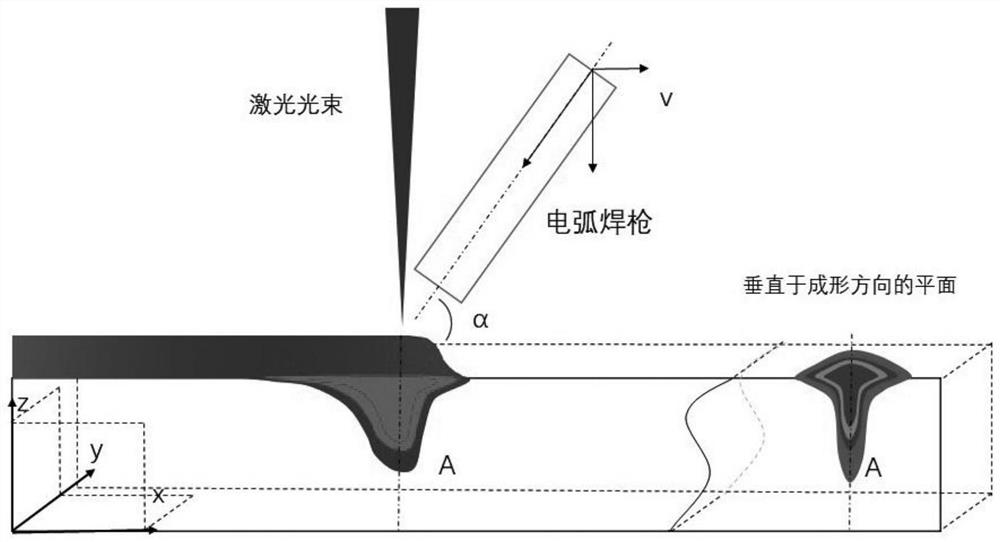

Method used

Image

Examples

Embodiment 1

[0030]The magnesium alloy repair and remanufacturing object in this example is an aircraft ZM5 flywheel part. During the use process, corrosion and wear are linked to produce volume damage. The laser profiler is used to measure the damage area in the area of 30mm×20mm×2mm in length, width and depth. within range. The method for performing magnesium alloy additive repair and remanufacturing on the magnesium alloy additive repair and remanufacture object includes the following steps:

[0031] S101. Treatment of damaged surface of magnesium alloy parts.

[0032] Use mechanical processing to open a groove with a length, width and depth of 31mm×21mm×3mm at the damaged part to remove the defect and its surface corrosion / wear products until the fresh metal surface is exposed. For crack damage, use the colorant flaw detection method Check whether the cracks are polished clean.

[0033] S102. Based on the geometric feature and volume determination of the damage, a multi-layer and m...

Embodiment 2

[0043] The magnesium alloy repair and remanufacturing object in this example is an aircraft ZM5 flywheel part. During the use process, corrosion and wear are linked to produce volume damage. The laser profiler is used to measure the damage area in the area of 4mm×2mm×1mm in length, width and depth. within range. The method for performing magnesium alloy additive repair and remanufacturing on the magnesium alloy additive repair and remanufacture object includes the following steps:

[0044] S201. Treatment of damaged surfaces of magnesium alloy parts. Use mechanical processing to open a groove with a length, width and depth of 4.5mm×2.5mm×1.5mm at the damaged part to remove defects and surface corrosion / wear products until the fresh metal surface is exposed. Use coloring for crack damage The chemical flaw detection method is used to detect whether the crack is polished clean.

[0045] S202. The geometric feature and volume determination based on the damage adopts a two-laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com