Cooling device for optical fiber drawing

A cooling device and wire drawing technology, applied in the direction of manufacturing tools, glass manufacturing equipment, etc., can solve the problems of reducing the cooling effect, temperature rise, temperature rise, etc., to achieve the effect of enhancing the cooling effect, enhancing the cooling capacity, and increasing the duration of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

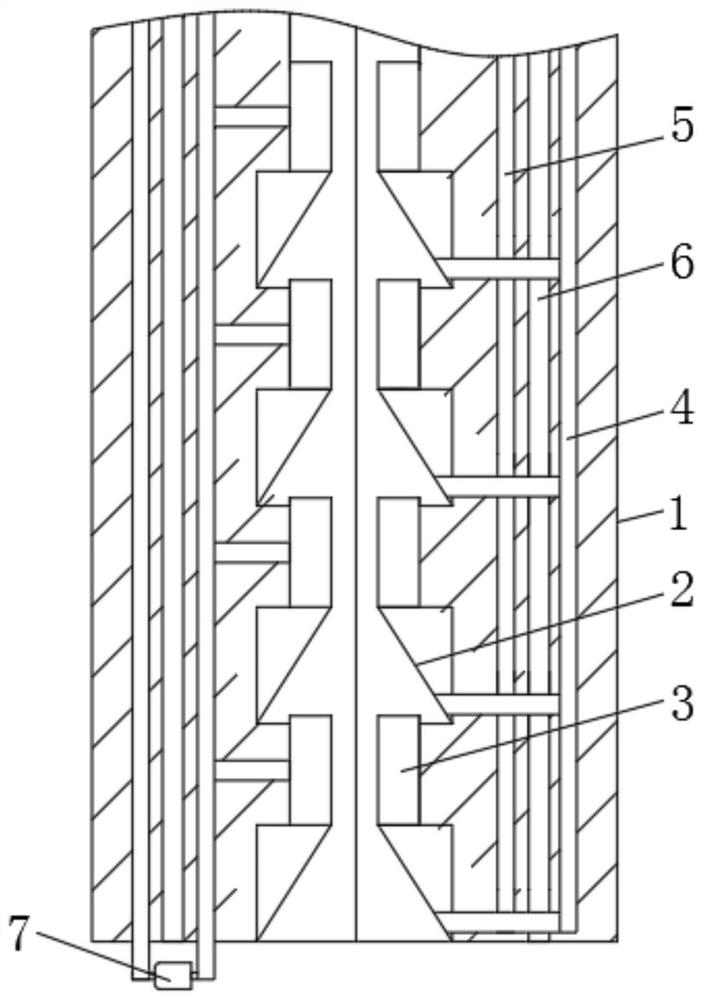

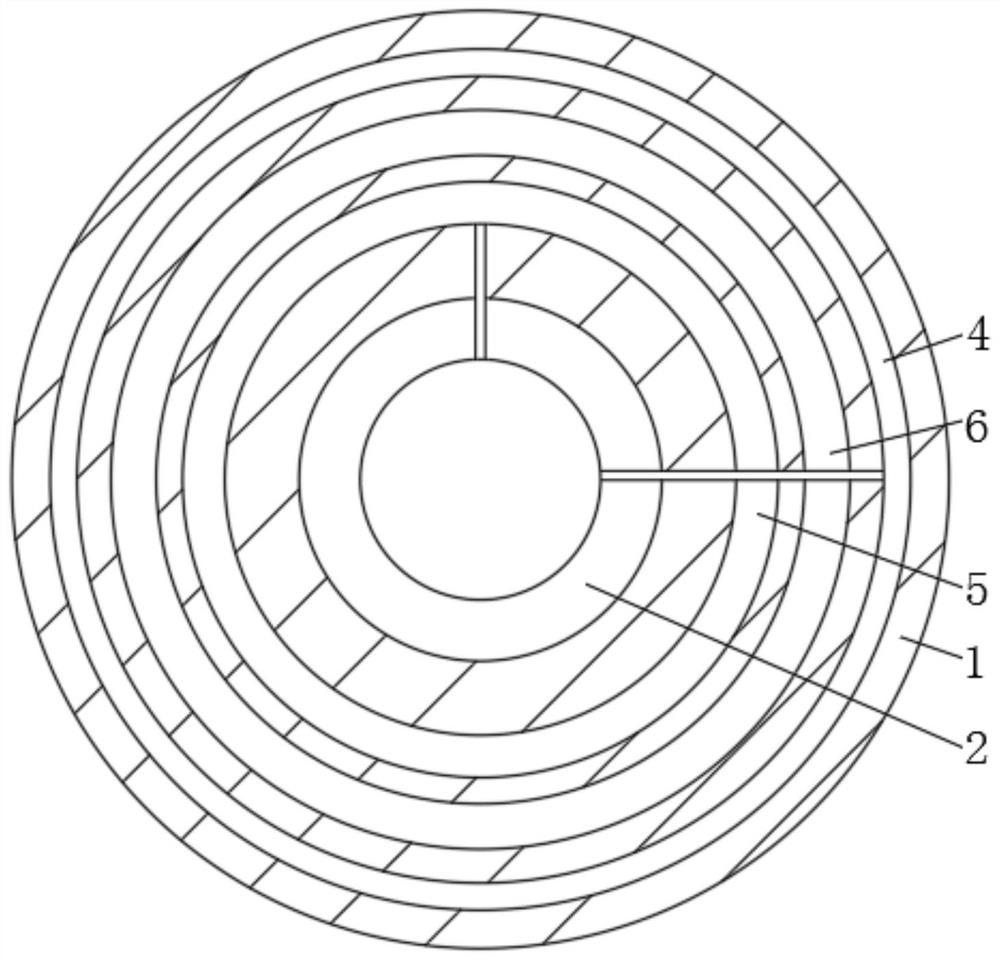

[0021] see Figure 1-2 , a cooling device for optical fiber drawing, comprising a tower body 1, the inner cavity of the tower body 1 injects cooling gas, and the inner wall of the tower body 1 is continuously provided with a cooling unit composed of an air blowing part 2 and an air suction part 3 from top to bottom , and in each unit, the suction piece 3 is arranged upstream of the blowing piece 2, with respect to the air-cooling flow direction, the blowing piece 2 and the suction piece 3 are respectively connected with an air outlet channel 4 and an air suction channel 5, and the blowing piece 2. The suction part 3, the air outlet channel 4 and the air suction channel 5 form an air-cooling cycle, that is, the cooling gas is sucked by the suction part 3, passes through the suction channel 5 and the air outlet channel 4, and then flows back through the suction part 3 To the inner chamber of the tower body 1, the optical fiber is cooled. The tower body 1 is provided with a water...

Embodiment 2

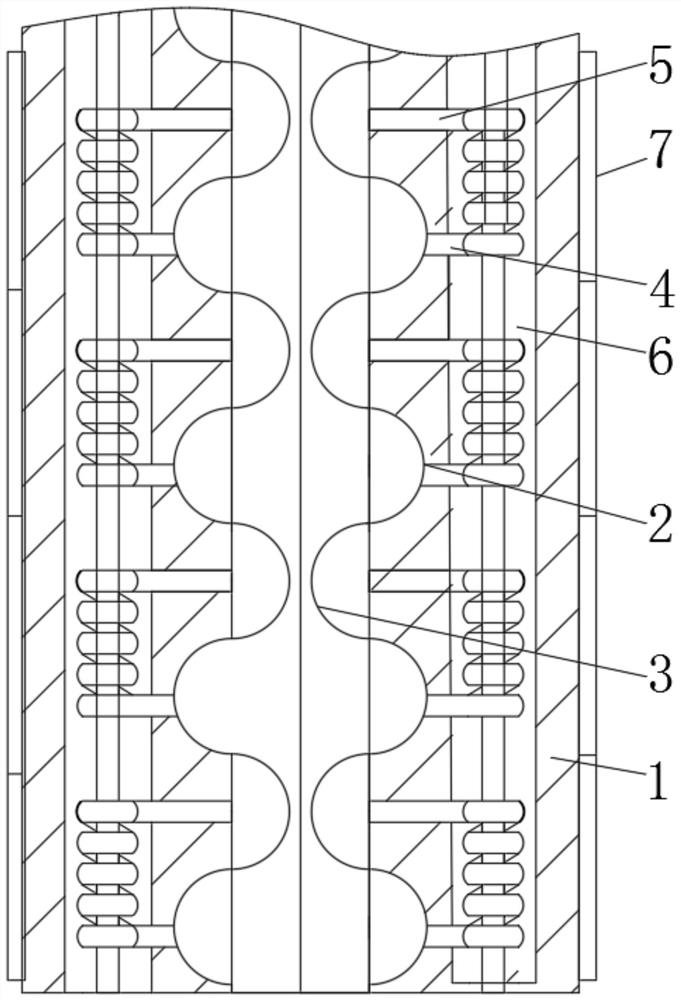

[0025] The difference from Embodiment 1 is that please refer to image 3 with Figure 4 , the blowing part 2 and the suction part 3 are both airbags, and the blowing part 2 is recessed toward the inner wall, and the suction part 3 protrudes toward the inner cavity. 7 is an electromagnet located on the side wall of the tower body 1, the electromagnet drives the magnet, and then drives the blowing part 2 and the suction part 3 to compress and relax, and the formation of the blowing part 2 and the suction part 3 is opposite, that is, the blowing part 2 When compressed, the suction part 3 relaxes, and a one-way valve is provided between the blowing part 2 and the suction part 3 and between the blowing part 2 and the suction part 3, and the blowing part 2 exhausts in one direction, and the suction The part 3 sucks air in one direction, and the gas flows from the suction part 3 to the blowing part 2 in one direction. Compared with the first embodiment, the gas flow path is shorter,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com