Foam material, ultrathin damping foam material layer for damping of AMOLED module, assembly and preparation method

A foam, ultra-thin technology, applied in the direction of film/sheet adhesives, adhesives, etc., can solve problems such as unfavorable environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0093]A method for preparing the ultra-thin foam material assembly for AMOLED module shock absorption, characterized in that it comprises the following steps:

[0094] S1, the synthesis of acrylate copolymer seed emulsion:

[0095] Add the monomer containing unsaturated carbon-carbon double bond, the first emulsifier and deionized water into the reaction kettle, under the condition of nitrogen protection, heat to 45-55°C and continuously stir and emulsify for 25-35 minutes, keep the reaction The device is under the condition of nitrogen protection, the initiator is dissolved in distilled water and then added dropwise to the reaction solution, the temperature is raised to 70-80°C, and the stirring reaction is continued for 3-4 hours to obtain the prepolymer emulsion A; the unsaturated carbon-carbon The weight ratio of the double bond monomer, the first emulsifier, the initiator and the deionized water is 40-60 parts / 0.5-5 parts / 0.05-0.1 parts / 40-60 parts.

[0096] Then massfra...

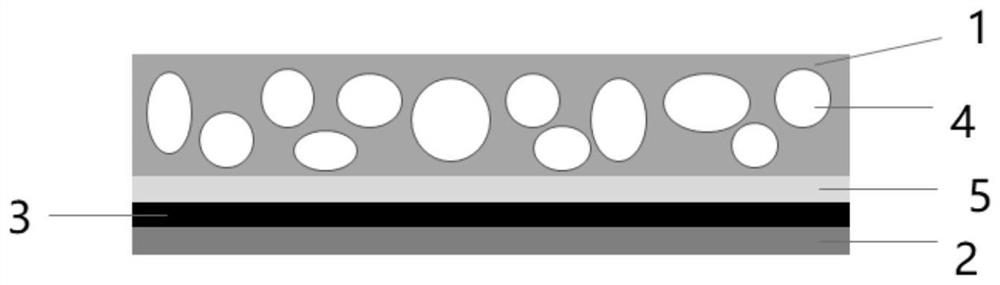

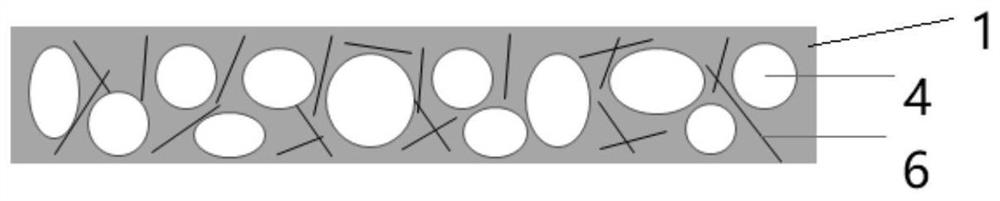

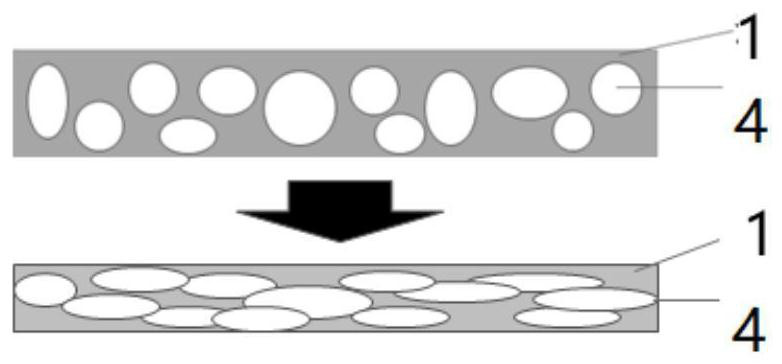

Embodiment 1

[0117] The ultra-thin foam assembly for AMOLED module shock absorption provided in this embodiment includes an ultra-thin shock-absorbing foam layer 1 and a release film layer 2, and the ultra-thin shock-absorbing foam layer and the release film layer pass through The adhesive layer 3 is bonded, and the thickness of the ultra-thin shock-absorbing foam layer is 0.05-0.5 mm. Its preparation method is as follows:

[0118] S1, the preparation of acrylate copolymer seed emulsion:

[0119] Add 20 grams of butadiene, 110 grams of styrene, 6 grams of sodium lauryl sulfate and 100 grams of deionized water into the reactor, and under nitrogen protection, heat to 50 ° C and continuously stir and emulsify for 30 minutes, keeping The reaction device was dissolved in 20 g of deionized water and 0.12 g of ammonium persulfate was dissolved in 20 g of deionized water and added dropwise to the reaction solution, the temperature was raised to 80 ° C, and the stirring reaction was continued for ...

Embodiment 2

[0133] The ultra-thin foam assembly for AMOLED module shock absorption provided in this embodiment includes an ultra-thin shock-absorbing foam layer 1 and a release film layer 2, and the ultra-thin shock-absorbing foam layer and the release film layer pass through The adhesive layer 3 is bonded, and the thickness of the ultra-thin shock-absorbing foam layer is 0.05-0.5mm. Its preparation method is as follows:

[0134] S1, preparation of acrylate copolymer seed emulsion

[0135] Add 20 grams of butadiene, 110 grams of styrene, 6 grams of sodium lauryl sulfate and 100 grams of deionized water into the reactor, and under nitrogen protection, heat to 50 ° C and continuously stir and emulsify for 30 minutes, keeping The reaction device was dissolved in 20 g of deionized water and 0.12 g of ammonium persulfate was dissolved in 20 g of deionized water and added dropwise to the reaction solution, the temperature was raised to 80 ° C, and the stirring reaction was continued for 3 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com