Composite casting product containing titanium carbide-based powder metallurgy product

A powder metallurgy and composite casting technology, applied in the field of metallurgy, can solve the problems of shedding, unreliable bonding, and high maintenance costs, and achieve the effects of extending service life, avoiding shedding and cracking, and satisfying wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The picks of coal mine excavation equipment are produced by composite melting and casting process.

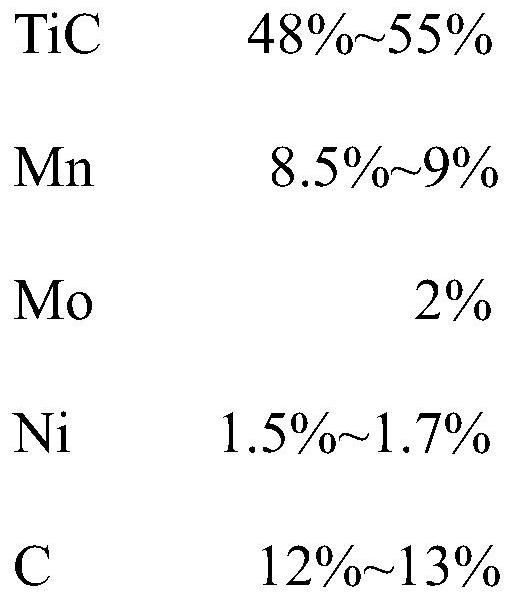

[0024] In this embodiment, the titanium carbide-based powder metallurgy product (TM50) includes the following components by mass percentage: 48% TiC, 8.5% Mn, 2% Mo, 1.5% Ni, 13% C, and 27% Fe. The titanium carbide-based powder metallurgy product (TM50) cemented carbide material is produced by sintering the above-mentioned components in proportion. The resulting titanium carbide-based powder metallurgy product (TM50) has a density of 6.5-6.6 and a hardness of HRA86-88. The matrix material is high manganese steel molten steel.

[0025] The following process steps are adopted:

[0026] The titanium carbide based powder metallurgy product (TM50) was placed in the top position of the working part in the pick die. Under the negative pressure environment, the high manganese steel matrix liquid steel is poured into the pick mold, and the pouring temperature is 1600 ℃. Where...

Embodiment 2

[0030] A drill bit for a rotary excavator is produced by a composite melting and casting process.

[0031] In this embodiment, the titanium carbide-based powder metallurgy product (TM45) includes the following components by mass percentage: 55% TiC, 9% Mn, 2% Mo, 1.7% Ni, 12% C, and 20.3% Fe. The titanium carbide-based powder metallurgy product (TM45) cemented carbide material is produced by sintering the above-mentioned components in proportion. The resulting titanium carbide-based powder metallurgy product (TM45) has a density of 6.4-6.5 and a hardness of HRA88-90. The matrix material also adopts molten steel of high manganese steel.

[0032] According to the process steps of the first embodiment above, the titanium carbide-based powder metallurgy product (TM45) was placed in the working part of the hammer drill mold. In a negative pressure environment, pour the matrix molten steel into the hammer drill mold, and the pouring temperature is 1500°C. Negative pressure enviro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com