Distributed optical fiber coal mine roof safety monitoring system and method

A distributed optical fiber and safety monitoring technology, which is applied in the direction of measuring devices, using optical devices to transmit sensing components, converting sensor outputs, etc., can solve the problems of temperature and strain cross-sensitivity, the inability to accurately measure temperature and strain, etc., to improve On-site safety, resolution of temperature and strain cross-sensitivity issues, effects of eliminating losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

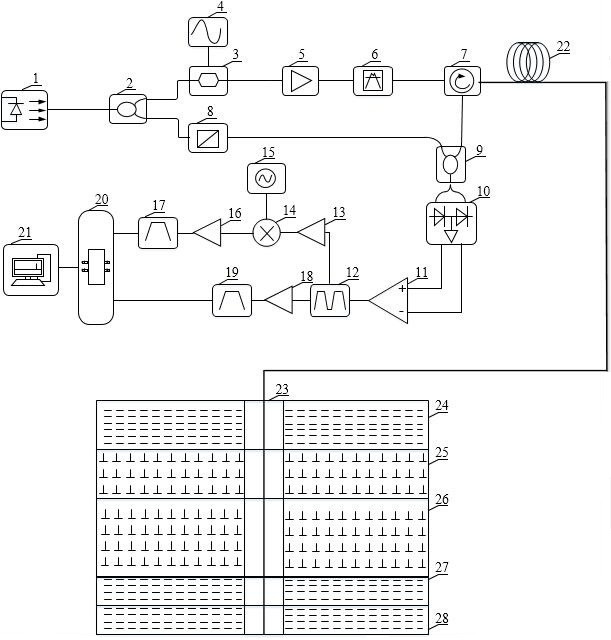

[0040] Such as figure 1 As shown, the distributed optical fiber coal mine roof safety monitoring system provided by the present invention includes: a narrow linewidth laser 1, a first optical coupler 2, an electro-optic intensity modulator 3, a pulse generator 4, an erbium-doped fiber amplifier 5, an optical filter device 6, optical circulator 7, acousto-optic modulator 8, second optical coupler 9, double-ended balanced detector 10, differential amplifier 11, dual-band bandpass filter 12, radio frequency power amplifier 13, mixer 14, microwave Source 15, first low-noise amplifier 16, first band-pass filter 17, second low-noise amplifier 18, second band-pass filter 19, data acquisition card 20, computer 21, GFPR optical cable 22, scientific research borehole 23, Unconsolidated layer 24, upper igneous rock 25, lower igneous rock 26, working face roof 27, coal seam 28.

[0041] Wherein, the output end of the narrow linewidth laser 1 is connected to the input end of the first opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com