Temperature monitoring and management method and system for reflow oven in ICT production line

A monitoring management and soldering furnace technology, applied in the field of reflow furnace temperature monitoring and management method and system field in the assembly process, can solve the problems of furnace temperature thermometer sampling method that cannot be correlated, thermometer consumption is large, spherical surface defects and other problems , to achieve the effect of cost control production efficiency and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

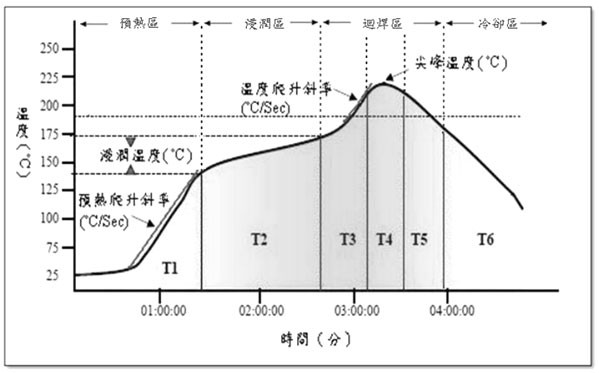

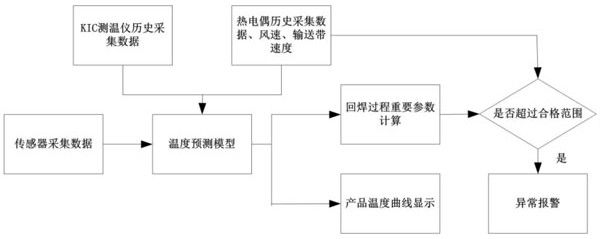

[0053] to combine Figure 1-Figure 2 The present invention is described in detail,

[0054] The invention provides a reflow furnace temperature monitoring and management system used in ICT production lines, including: several sensors, KIC thermometer, reflow furnace temperature monitoring module, temperature prediction model, response surface model, assembly furnace temperature curve platform ;

[0055] The several sensors are used to obtain the wind speed, temperature and conveyor belt speed in the reflow furnace; the KIC thermometer is used to obtain the KIC temperature curve of the reflow furnace; the reflow furnace temperature monitoring module monitors the temperature obtained by the sensor in real time Whether the wind speed, temperature and conveyor belt speed exceed the preset upper and lower limits; the temperature prediction model o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com