Method for extracting grease in food and application thereof

An extraction method and oil technology, which is applied in the field of oil extraction in food, can solve the problems of large amount of oil, easy oxidation, and influence on detection results, etc., and achieve the effect of low toxicity and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0041] First Embodiment: Precision Test

[0042] In this example, 6 representative samples commonly found on the market were selected, including 3 samples of peanut butter and 3 samples of sesame paste. Oil and fat were prepared according to the following steps, and the acid value and peroxide value were measured respectively. The specific process is as follows:

[0043] (1) Weigh 100g of each sample into a stoppered container, add 100mL of acetone-water mixed solvent (the volume ratio of acetone and water is 1:1) as a flocculant, then vigorously stir and mix with a glass rod, and then add 300mL Petroleum ether, plugged, shaken to extract. After standing and stratifying for 40 minutes, take the upper clear and transparent organic phase layer, filter the organic phase with anhydrous sodium sulfate filter paper for dehydration, and collect the filtrate in a brown glass rotary evaporator for future use.

[0044] (2) Rotate the filtrate obtained in step (1) to remove the solvent...

no. 2 example

[0053] Second embodiment: accuracy test

[0054] Due to the determination of acid value and peroxide value, conventional methods such as standard recovery test and quality control sample test cannot be used to investigate the accuracy. According to the accuracy evaluation basis of GB / T 27417-2017 "Guidelines for Confirmation and Verification of Chemical Analysis Methods for Conformity Assessment", the bias of another method can be evaluated according to the known nationally recognized reference method, and the t-test method is used to compare the analytical method. The significance of bias between them was assessed.

[0055] The current national standard directly detects the method of acid value and peroxide value in animal and vegetable oils and fats is accurate and reliable. We only need to verify that the extraction and preparation methods of peanut butter and sesame butter sample oils are accurate and reliable to ensure the accuracy of the method of the present invention...

no. 3 example

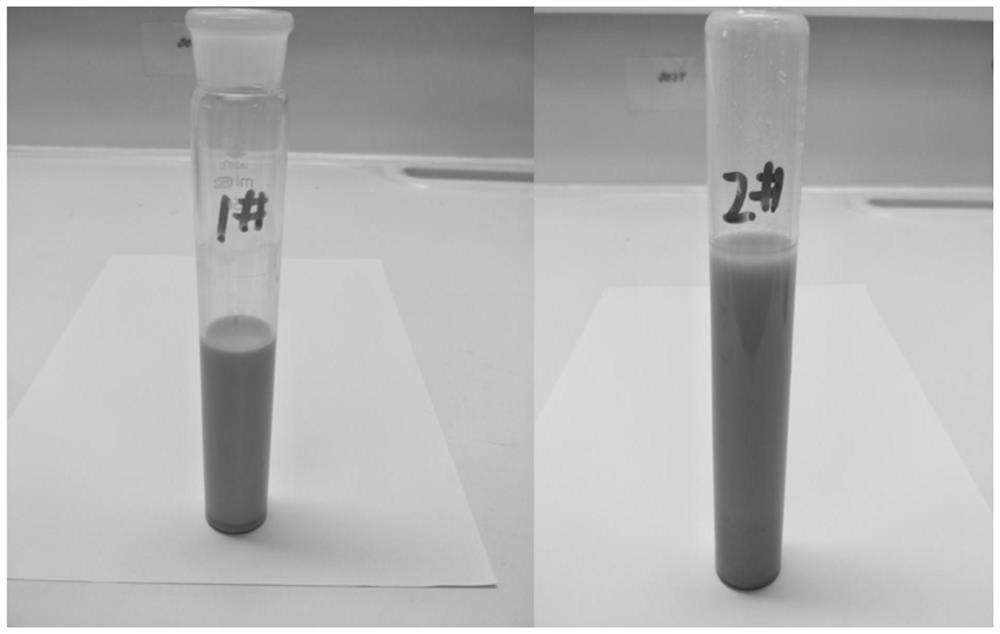

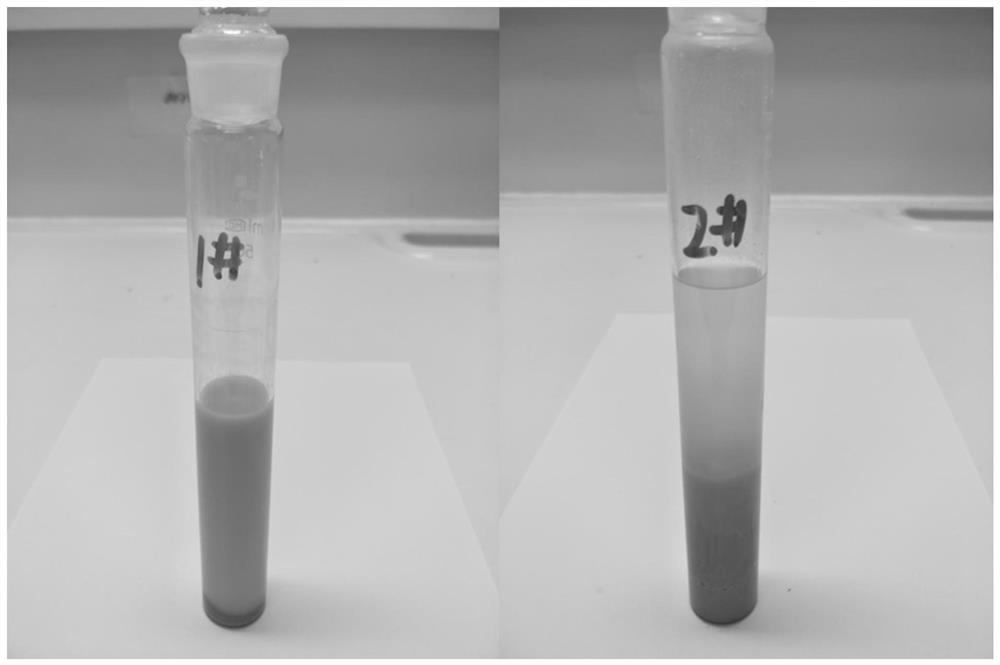

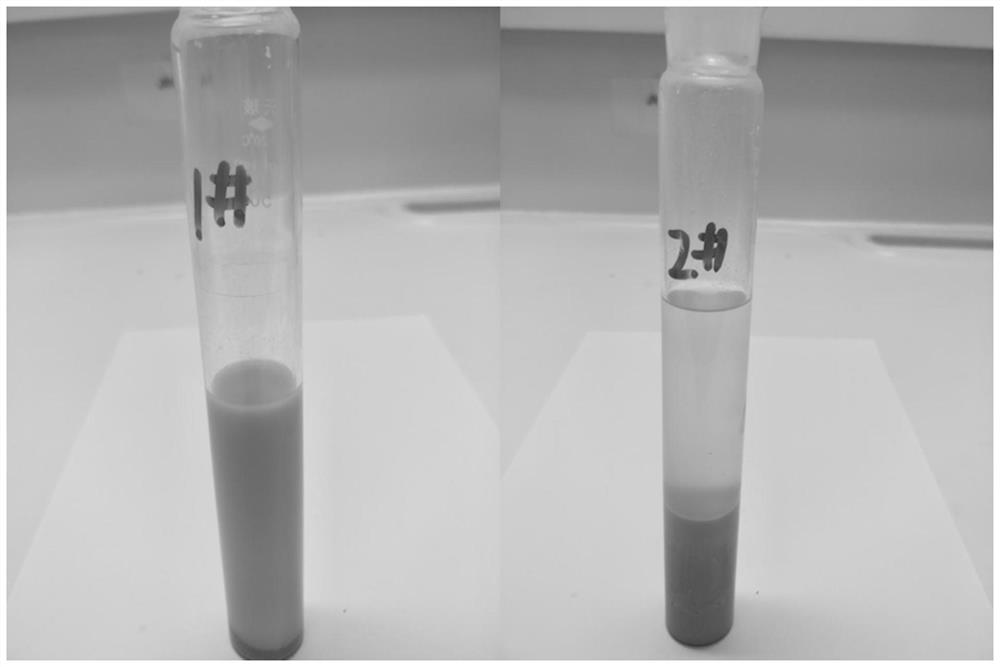

[0063] The 3rd embodiment: national standard method and the method of the present invention process the sample back static state comparative experiment

[0064] In order to visually compare and contrast the national standard method (GB 5009.227-2016 or GB 5009.229-2016) and the state of standing after the sample is processed by this method, the same sesame paste sample is selected for the following steps.

[0065] Process the sample according to the national standard method: Weigh 10g of sesame paste sample into a 1# stoppered test tube, add 30mL of petroleum ether, shake and extract, then let it stand for different times, and observe its state.

[0066] Process sample according to the method of the present invention: take by weighing 10g sesame paste sample in 2# stopper test tube, add 10mL acetone-water mixed solvent (the volume ratio of acetone and water is 1:1) as flocculant, then vigorously stir and mix with glass rod Mix well, then add 30mL of petroleum ether, shake to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com