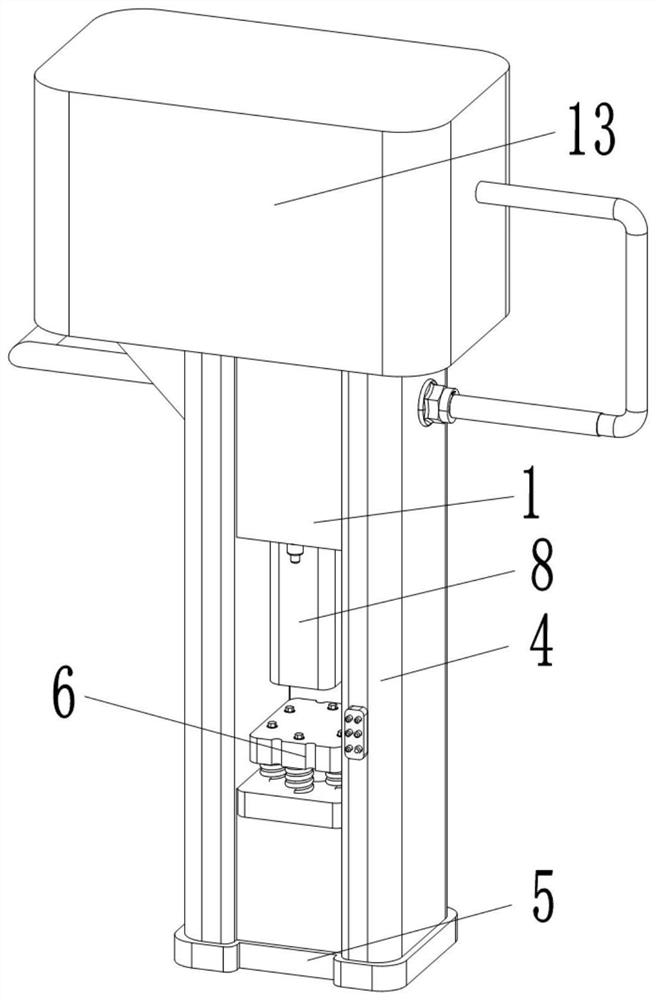

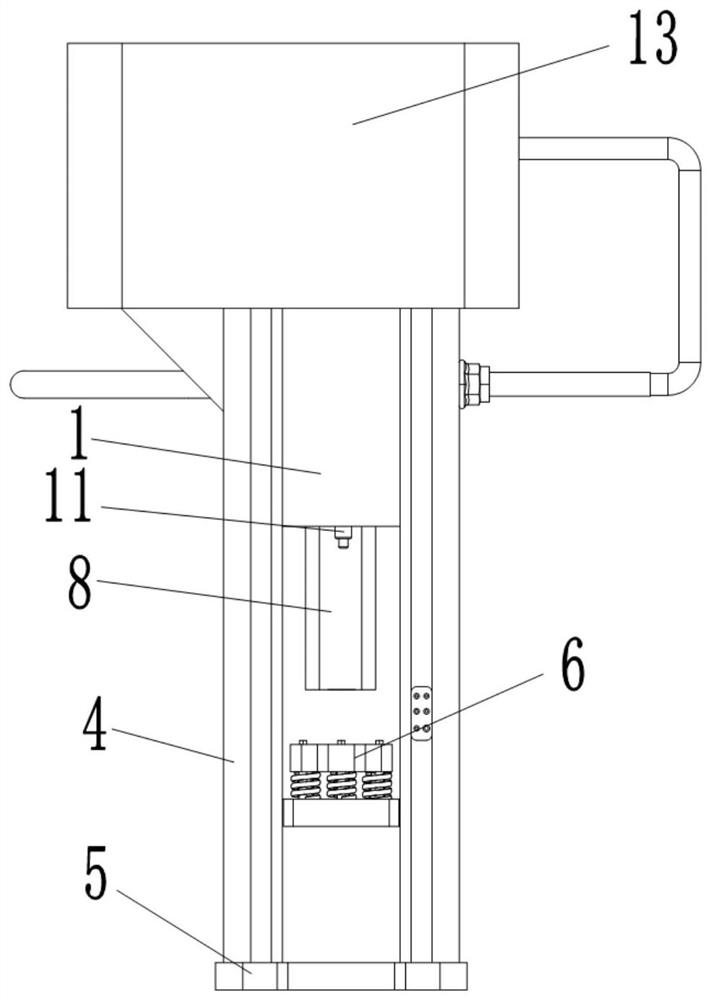

Numerical control press machine based on Internet of Things

A technology of presses and the Internet of Things, applied in the field of presses, can solve problems that affect the use of the management system, instability, looseness, etc., and achieve the effects of improving safety, increasing service life, and reducing impact frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

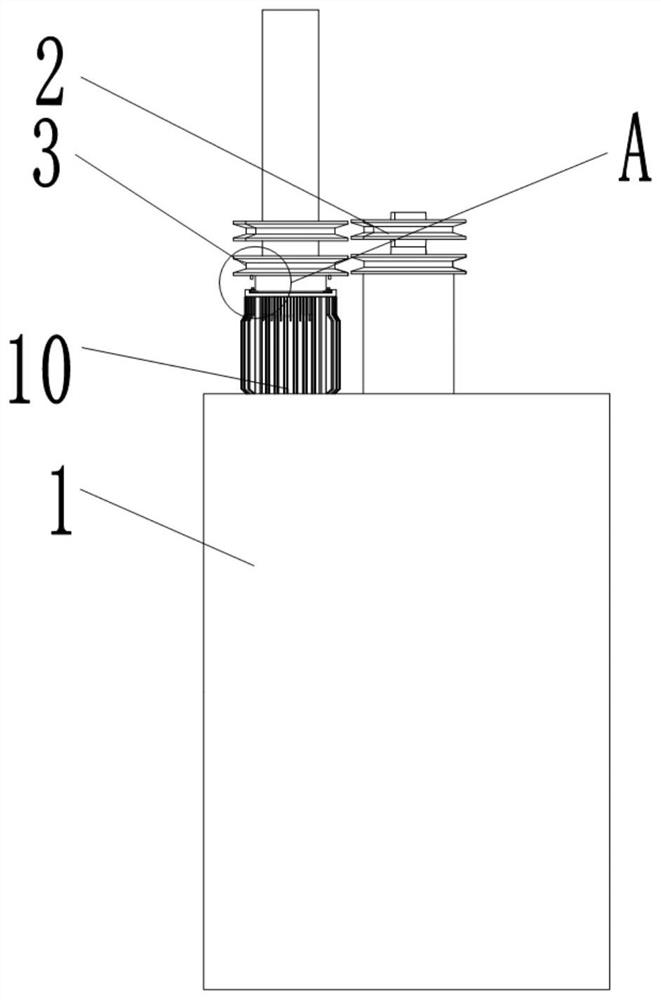

[0056] When the workpiece is normally extruded in Example 1, during the transition of the reciprocating screw 7 from descending to ascending, the guide rod 902 may not be at the crossover switching point of the forward and reverse screw grooves of the reciprocating screw 7 during the switching process, which will cause the hammer to If the hammering part 8 continues to move down, the impact force of the hammering part 8 on the workpiece will be greater than the first preset pressure value; at the same time, with the gradual development of modern factories, the method of using Internet of Things technology to monitor the press in real time is also Gradually popularized, and when using the Internet of Things technology for monitoring, the press often connects to the data server through the client VPN router, and then the data server completes the data processing and sends the processing results to the management computer, which is convenient People monitor the working status of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com