Preparation method of nitrided compound acidic wastewater treatment agent and prepared treatment agent

A technology of acid wastewater and treatment agent, which is applied in water/sewage treatment, chemical instruments and methods, neutralization water/sewage treatment, etc., can solve the problems of high cost and transfer of treatment agent pollution, and achieve low preparation cost and obvious effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation method of nitriding compound acidic wastewater treatment agent comprises the following steps:

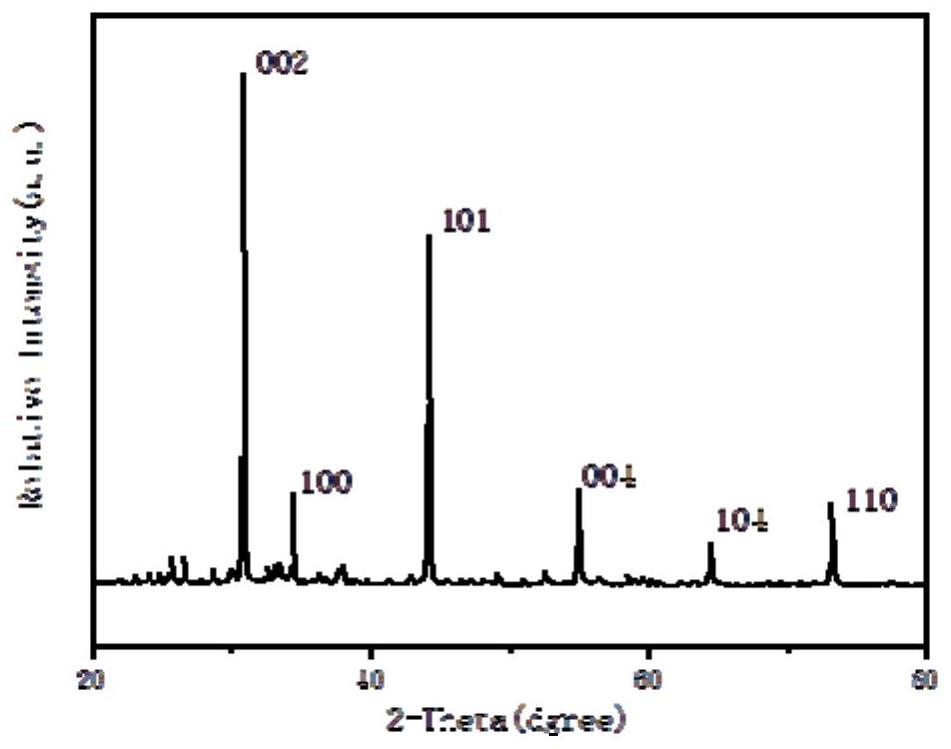

[0037] (1) Weigh 3.00g of borax and 6g of melamine respectively, and the ratio of the substances is 1:2. Place in a 100ml beaker, add 50ml of water, and place in a magnetic stirrer at 75°C until completely dissolved. The above solution was transferred to the reactor while hot, and kept at 100° C. for 5 h. After the reaction was completed and cooled to room temperature, the precipitated crystals were suction filtered, washed, and dried to obtain intermediate product A.

[0038] (2) The prepared intermediate product A was calcined at 600°C for 2 h under anaerobic conditions, removed from the crucible and ground to obtain powdered sample B.

[0039] (3) Preparation of precursor sol C: Dissolve 2 grams of powdery sample B in 50ml of pure water, then add 2 grams of chitosan, and stir continuously under the condition of heating at 100°C until a sol-like liquid is ...

Embodiment 2

[0043] The preparation method of nitriding compound acidic wastewater treatment agent comprises the following steps:

[0044] (1) Weigh 3.00g of boric acid and 6g of ammonium bicarbonate respectively, and the ratio of the substances is 1:2. Place in a 100ml beaker, add 60ml of water, and place in a magnetic stirrer at 90°C until completely dissolved. The above solution was transferred to the reactor while hot, and kept at 90° C. for 5 h. After the reaction was finished, after cooling to room temperature, the precipitated crystals were suction filtered, washed, and dried to obtain intermediate product A.

[0045] (2) The prepared intermediate product A was calcined at 800°C for 3 h under anaerobic conditions, removed from the crucible and ground to obtain powdered sample B.

[0046] (3) Preparation of precursor sol C: Dissolve 2 grams of powdery sample B in 50ml of pure water, then add 2 grams of polyvinyl alcohol, and stir continuously under the condition of heating at 95°C ...

Embodiment 3

[0050] The preparation method of nitriding compound acidic wastewater treatment agent comprises the following steps:

[0051] (1) Weigh 3.00g of boric acid and 6g of urea respectively, and the ratio of the substances is 1:2. Place in a 100ml beaker, add 70ml of water, and place in a magnetic stirrer at 100°C until completely dissolved. The above solution was transferred to the reactor while hot, and kept at 100° C. for 5 h. After the reaction was completed and cooled to room temperature, the precipitated crystals were suction filtered, washed, and dried to obtain intermediate product A.

[0052] (2) The prepared intermediate product A was calcined at 700 ° C for 2 h under anaerobic conditions, removed from the crucible and ground to obtain powdered sample B.

[0053] (3) Preparation of precursor sol C: Dissolve 2 grams of powdered sample B in 50ml of pure water, then add 2 grams of peach gum, and stir continuously under the condition of heating at 105°C until a sol-like liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com