Reverse osmosis concentrated water treatment process for enhancing activated carbon adsorption through catalytic ozonation

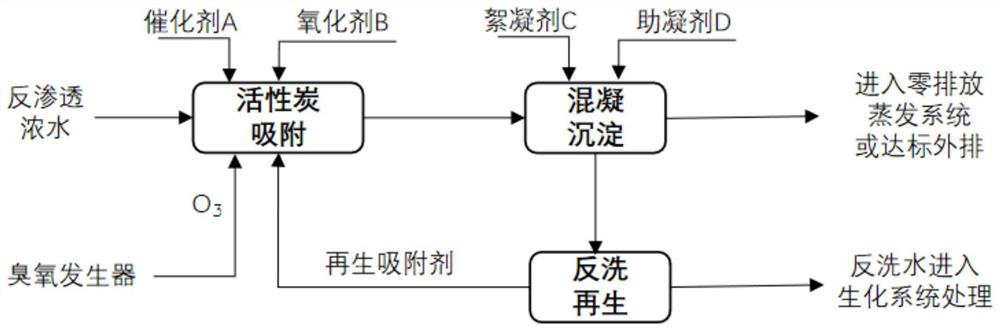

A technology of ozone catalytic oxidation and activated carbon adsorption, which is applied in the direction of oxidation water/sewage treatment, water/sewage treatment, water treatment parameter control, etc., to achieve the effect of simple process flow, low salt content and good synergistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A reverse osmosis concentrated water treatment process in which ozone catalytic oxidation strengthens activated carbon adsorption. The main processing units used in this embodiment are activated carbon oxidation adsorption, coagulation sedimentation, and activated carbon backwash regeneration. The reverse osmosis concentrated water quality indicators used in the experiment are pH 8.09, water temperature 25°C, CODCr content 82.16mg / L, TDS content 3250mg / L, and the salts included are mainly sodium chloride and sodium sulfate.

[0045] Including the following steps:

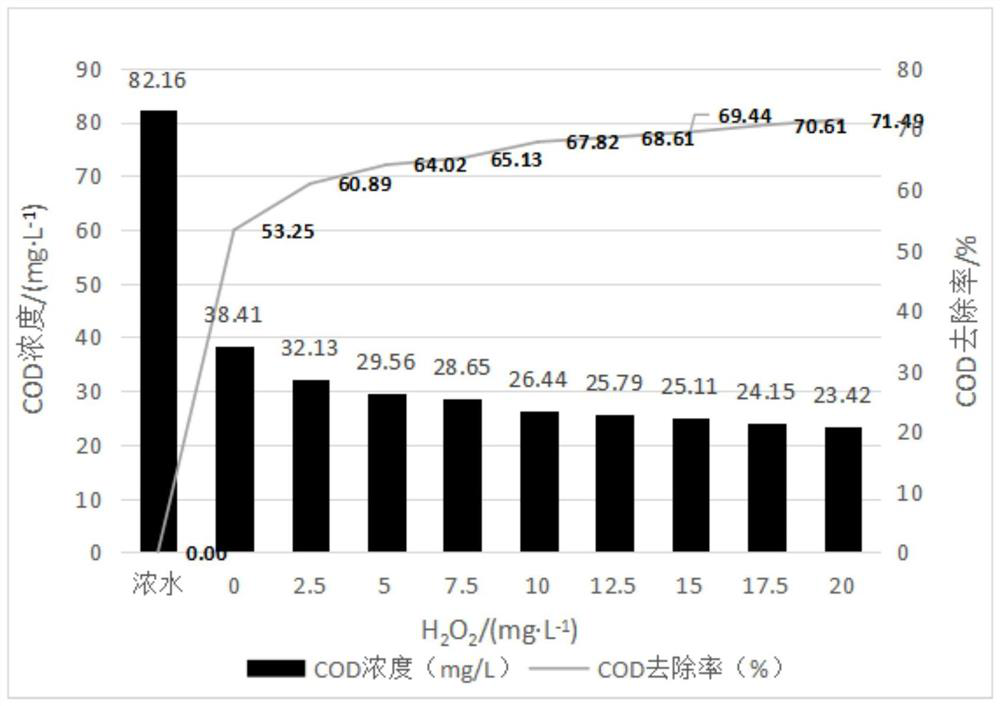

[0046] (1) Oxidation adsorption: Take 1000ml reverse osmosis concentrated water for experiment, the diameter of the experimental reaction column is 50mm, and the height is 1500mm. The amount of powdered activated carbon was added to the reverse osmosis concentrated water at 1.0g / L, and ferrous sulfate heptahydrate (FeSO 4 ·7H 2 O) The dosage is 60mg / L, and 20mg / L of H is added to the reverse osmosis concent...

Embodiment 2

[0051] A reverse osmosis concentrated water treatment process in which ozone catalytic oxidation strengthens activated carbon adsorption. The main processing units used in this embodiment are activated carbon oxidation adsorption, coagulation sedimentation, and activated carbon backwash regeneration. The water quality index of reverse osmosis concentrated water used in the experiment is: pH value is 6.99, water temperature is 25°C, COD Cr The content is 150.32mg / L, the TDS content is 4550mg / L, and the salts included are mainly sodium chloride and sodium sulfate.

[0052] Including the following steps:

[0053] (1) Oxidation adsorption: Take 1000ml reverse osmosis concentrated water for experiment, the diameter of the experimental reaction column is 50mm, and the height is 1500mm. The amount of powdered activated carbon added to reverse osmosis concentrated water is 0.5g / L plus 1.5g / L powdered activated coke, and ferrous sulfate heptahydrate (FeSO 4 ·7H 2 O) The dosage is 90...

Embodiment 3

[0057] A reverse osmosis concentrated water treatment process in which ozone catalytic oxidation strengthens activated carbon adsorption. The main processing units used in this embodiment are activated carbon oxidation adsorption, coagulation sedimentation, and activated carbon backwash regeneration. The water quality index of reverse osmosis concentrated water used in the experiment is: pH value is 7.86, water temperature is 25°C, COD Cr The content is 230.11mg / L, the TDS content is 6872mg / L, and the salts included are mainly sodium chloride and sodium sulfate.

[0058] Including the following steps:

[0059] (1) Oxidation adsorption: Take 1500ml reverse osmosis concentrated water for experiment, the diameter of the experimental reaction column is 50mm, and the height is 1500mm. The amount of powdered activated carbon added to reverse osmosis concentrated water is 1.0g / L plus 1.5g / L powdered activated coke, and ferrous sulfate heptahydrate (FeSO 4 ·7H 2 O) dosage is 120mg / ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap