Preparation method for treating and recycling coal tar hydrogenation wastewater

A technology for wastewater treatment and coal tar, which is applied in heating water/sewage treatment, ammonia preparation/separation, degassed water/sewage treatment, etc. The effect of less land occupation, easy operation of oil collection or sludge discharge, and high utilization rate of facilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

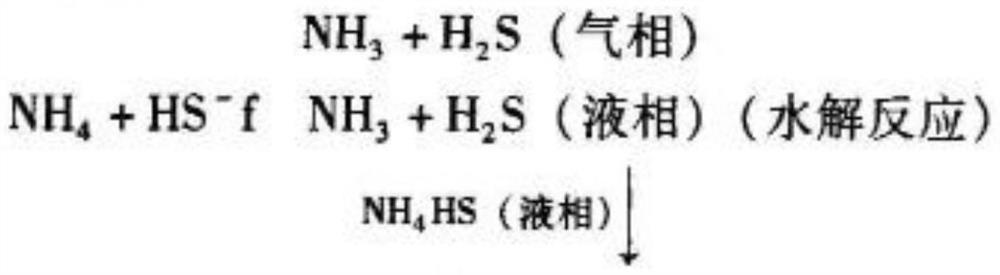

Method used

Image

Examples

Embodiment Construction

[0019] The preparation method for treating and recycling coal tar hydrogenation wastewater comprises the following steps:

[0020] S1: Deoiling treatment of coal tar hydrogenation wastewater;

[0021] (1). Discharge the oil-containing wastewater into the sewage treatment pool for centralized treatment;

[0022] (2). Prepare treatment and purification equipment: sewage regulating tank. The sewage regulating tank is divided into an outer tank and an inner tank. The sewage regulating tank is equipped with a chamber for a hydrocyclone separation area and a sedimentation separation area, and the sedimentation separation The chamber of the zone is an inner tank, and the inner tank is equipped with a hydrocyclone, an automatic oil skimmer and a settling cone, and is connected through the hydrocyclone, the automatic oil skimmer and the settling cone in the inner tank. into a complete system, and then through the siphon connecting pipes of the inner and outer tanks, the peripheral wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com