Self-repairing transparent super-hydrophobic polyamide-imide composite film and preparation method thereof

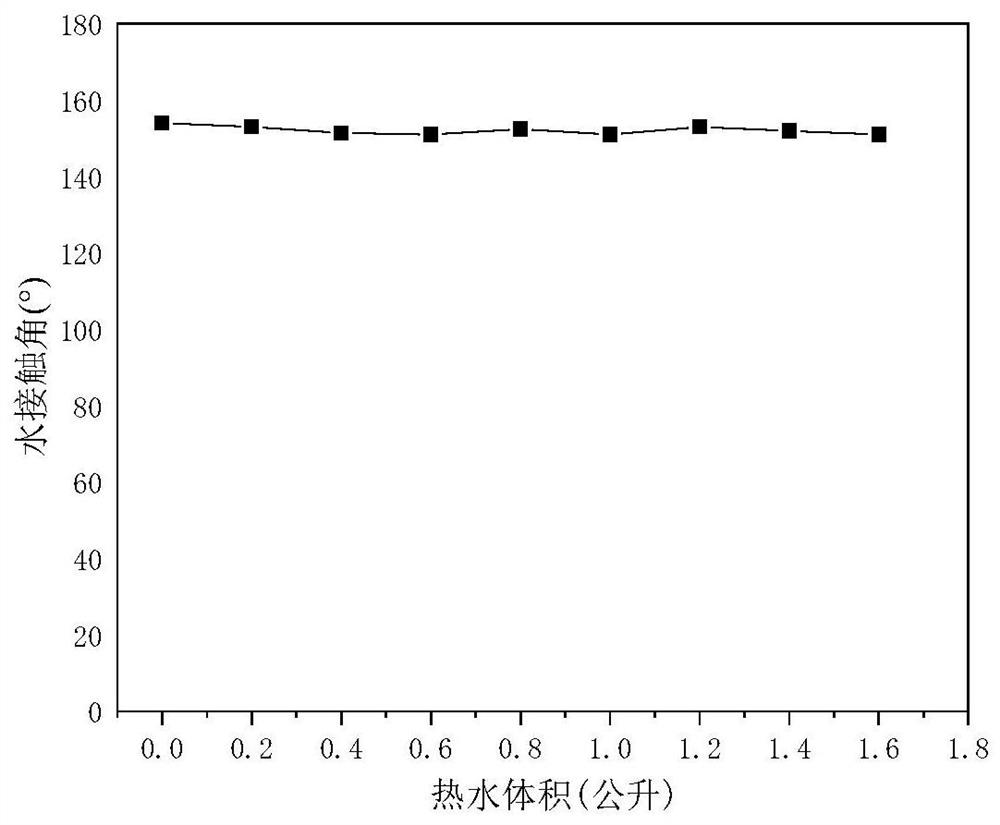

A water polyamide-imide and polyamide-imide technology is applied in the field of self-healing transparent super-hydrophobic polyamide-imide composite film and its preparation, which can solve the problem of weak adhesion between coating and substrate and loss of super-hydrophobicity. performance, easy to be impacted or worn, etc., to achieve good self-healing function, low cost, and improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

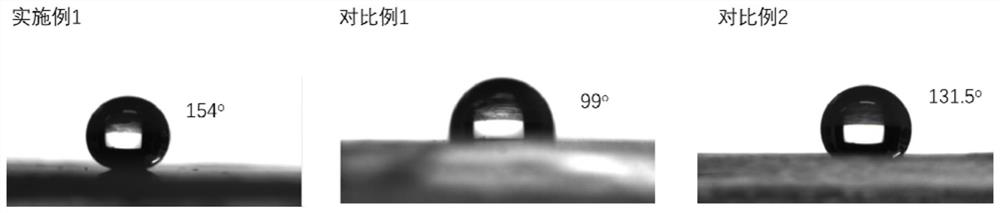

Embodiment 1

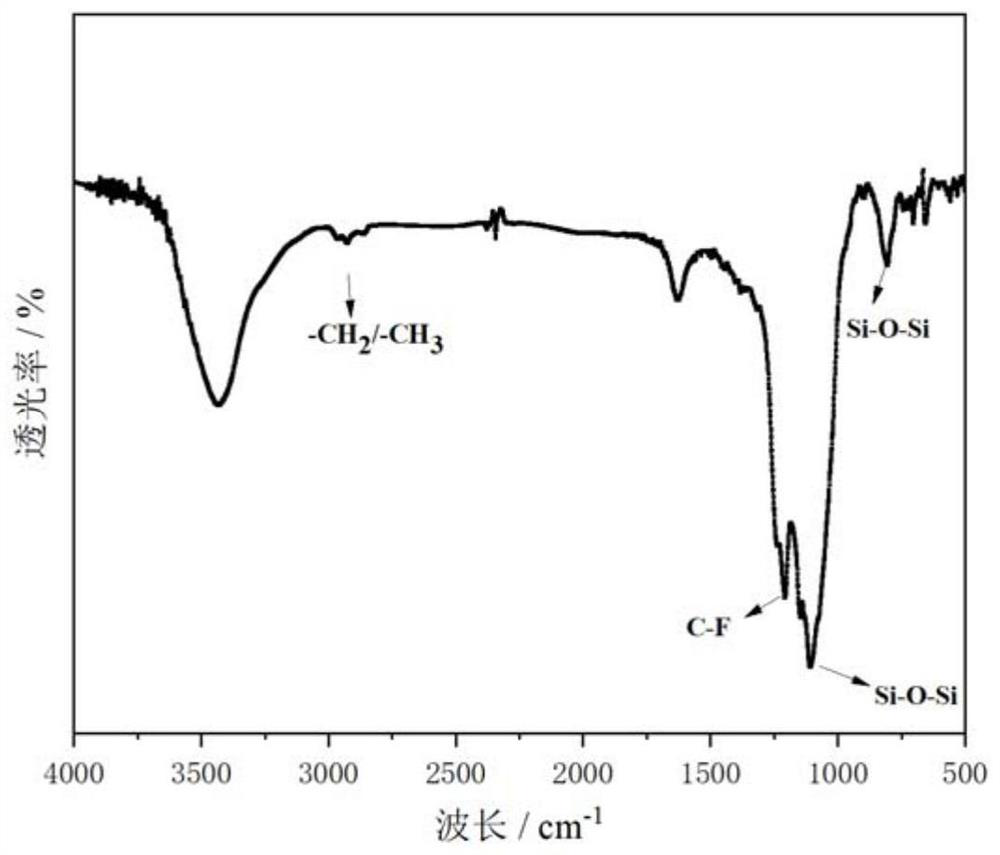

[0035] (1) Modification of silica

[0036] Add 2g of silicon dioxide and 100mL of deionized water into the flask, then add 1g of non-ionic fluorosurfactant Capstone FS-3100, stir vigorously at room temperature for 0.8 hours, and then vibrate ultrasonically for 0.2 hours. The suspension was then treated with a cell disruptor for 0.6 hours. Finally, 2 mL of the silica modifier perfluorodecyltrimethoxysilane was slowly added dropwise into the emulsion, and the stirring was continued for 15 hours at a speed of 2000 rpm.

[0037] (2) Preparation of self-healing transparent superhydrophobic polyamide-imide composite film

[0038] The polyamide-imide that step (1) is selected adopts N-methylpyrrolidone to be mixed with concentration and be 20gmL -1 The solution is coated on the glass substrate and dried at 80°C for 6 hours to obtain a polyamideimide wet film with a thickness of 30 μm. Then, the modified silica emulsion is 30 cm away from the base layer and sprayed at a pressure of ...

Embodiment 2

[0040] The difference between this embodiment and embodiment 1 is that the solvent in step (1) is ethanol, and other treatment means are consistent with embodiment 1.

Embodiment 3

[0042] The difference between this example and Example 1 is that the silica modifier in step (1) is nonafluorohexyltriethoxysilane, and other treatment methods are consistent with Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com