Deep-cycle long-life lead-acid storage battery lead paste for parking, battery thereof and manufacturing process method of battery

A lead-acid battery, deep cycle technology, applied in lead-acid battery electrodes, lead-acid batteries, lead-acid battery construction and other directions, can solve the problem that the battery life can not meet the user's requirements and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

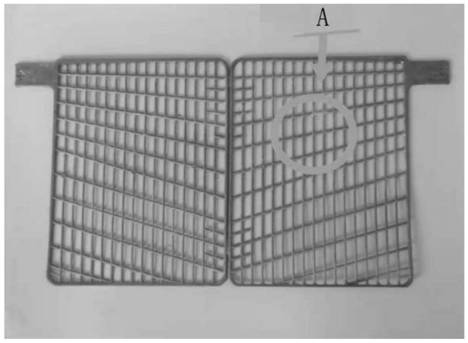

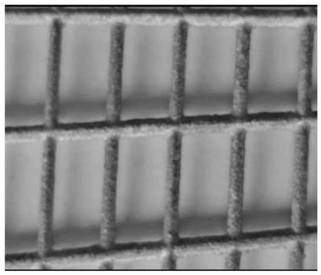

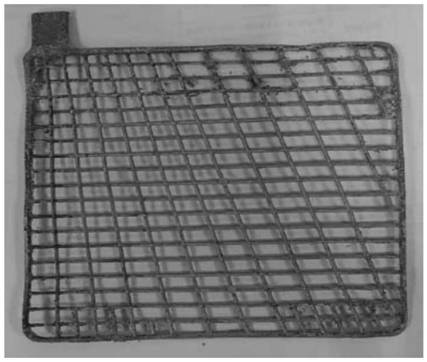

Image

Examples

Embodiment 1

[0054] The deep-cycle long-life lead-acid battery for parking in this embodiment includes a positive grid, a positive lead paste coated on the positive grid, a negative grid, and a negative lead paste coated on the negative grid, wherein, The positive lead paste is prepared from the following mass parts: 75kg of lead powder, 7.0kg of sulfuric acid solution, 10kg of water, 8kg of red lead, 0.15kg of antimony trioxide and phosphoric acid, and 0.08kg of polyester fiber; the negative lead paste is composed of the following The substances in parts by mass were prepared: 83kg of lead powder, 6.6kg of sulfuric acid solution, 9kg of water, 0.66kg of superfine barium sulfate, 0.2kg of Norwegian A-type lignin, 0.3kg of humic acid, 0.2kg of acetylene black, and 0.05kg of polyester fiber .

[0055] Its preparation method comprises the following steps:

[0056] (1) Age hardening of the grid and formation of corrosion film on the surface of the grid: Put the positive grid and the negative ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com