Clamping tool for servo motor driver maintenance

A technology of servo motors and drives, which is applied to workbenches, manufacturing tools, cleaning methods and appliances, etc. It can solve the problems of inability to adjust, no clamping of servo motor drives, single structure, etc., and achieve the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

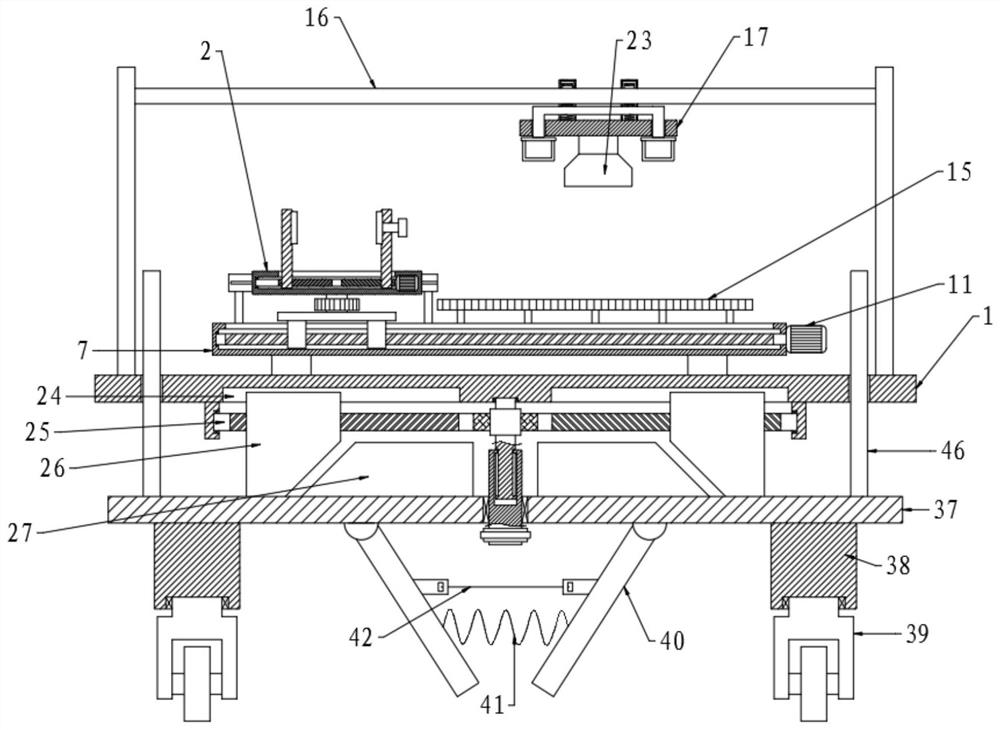

[0036] Please refer to the accompanying drawings, the present invention provides a technical solution: a tooling clamp for servo motor driver maintenance, including a workbench 1, a fixed assembly and a moving assembly are arranged on the workbench 1, and a support frame 16 is provided above the workbench 1 to support A blower 23 is provided below the frame 16, a base plate 37 is provided below the workbench 1, a lifting assembly is provided between the workbench 1 and the base plate 37, and some support columns 38 are provided below the bottom surface of the base plate 37.

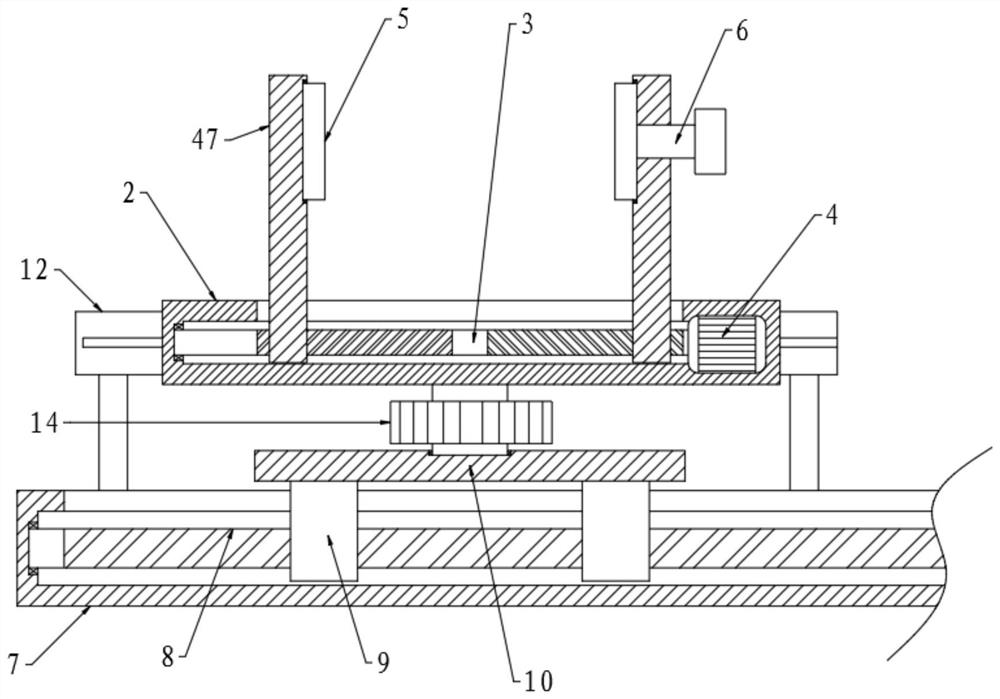

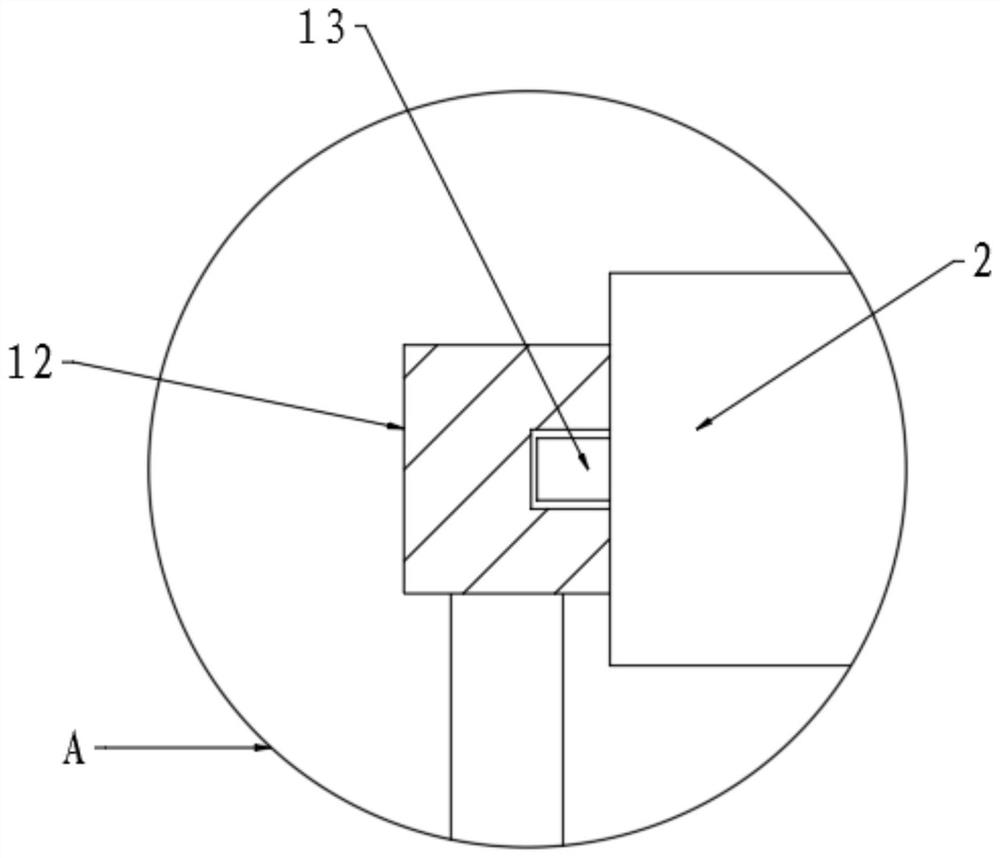

[0037] Wherein, the fixed assembly includes a fixed box 2, and the inside of the fixed box 2 is connected to a No. 1 screw mandrel 3 for rotation, and the right end of the No. 1 screw mandrel 3 is connected to a No. 1 motor 4, and the thread directions on the left and right sections of the No. 1 screw mandrel 3 are opposite. And be respectively threaded with fixed frame 47, the upper end of fixed frame 47 ...

Embodiment 2

[0043] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the top of the blower 23 is fixed with a loading plate 17, and there are two sliding tubes 18 on the left and right above the loading plate 17, and the inside of the sliding tube 18 is Sliding sleeve limited tube 19, the top of the loading plate 17 is provided with a control rod 20, the bottom ends of the left and right sides of the control rod 20 all slide downwards to stretch out the loading plate 17, and are fixed with a pull ring 22, the control rod 20 passes through the sliding tube 18 and is slidably connected in the sliding tube 18 in the vertical direction. The bottom end of the limit tube 19 is fixed above the control rod 20, and the bottom surface of a section in the sliding tube 18 on the control rod 20 is fixed. There is a No. 1 spring 21 , and the upper part of the support frame 16 passes through the sliding tube 18 and the limit tube 19 .

[0044] The sta...

Embodiment 3

[0046] The structure of this embodiment is basically the same as that of Embodiment 1. The difference is that the lifting assembly includes a rotating shaft 25 rotatably connected to the bottom surface of the workbench 1. The left and right sections of the rotating shaft 25 are provided with threads in opposite directions, and the middle part is provided with There is a worm 28, and the left and right sides of the bottom surface of the workbench 1 are provided with chute 24, and the chute 24 is slidably connected with a moving inclined block 26. Connected on the left and right sections of the rotating shaft 25, the left and right sides of the top surface middle part of the bottom plate 37 are provided with fixed inclined blocks 27 corresponding to the movable inclined blocks 26, and the front side of the workbench 1 is also provided with a control mechanism.

[0047] Wherein, the middle of the bottom surface of the workbench 1 is rotatably connected with a rotating rod 30, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com