Method for synthesizing naphthalene-based water reducer from residues of phthalic anhydride prepared by naphthalene method

A technology of naphthalene-based water reducer and phthalic anhydride, which is applied in the field of naphthalene-based water reducer synthesized from the residue of phthalic anhydride prepared by the naphthalene method, which can solve the problems of large fluctuations in market supply and high production costs, so as to reduce production costs and hinder cement hydration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

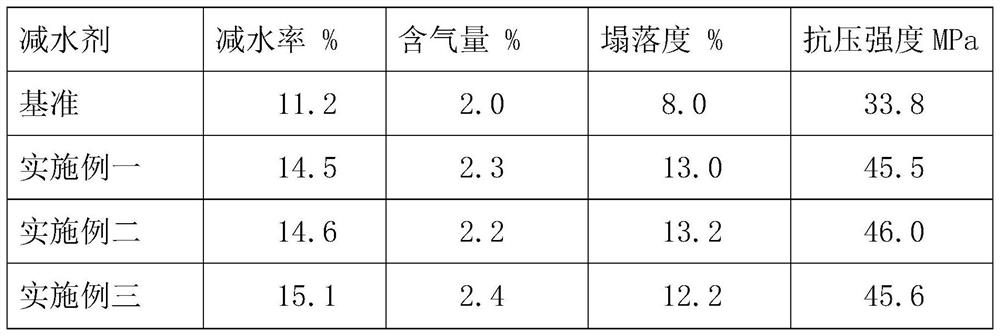

Examples

Embodiment 1

[0019] Embodiment 1. The present invention provides a technical solution: a method for synthesizing naphthalene-based water reducer from the residue of phthalic anhydride prepared by naphthalene method, comprising the following steps;

[0020] Step 1: Take 35 parts of phthalic anhydride residues and grind them through crushing equipment, then put the crushed phthalic anhydride residues into the reaction kettle, stir the phthalic anhydride residues, slowly drop 5 parts of concentrated sulfuric acid into the stirring process, and control the temperature at 110 minutes at 220°C;

[0021] Step 2: Cool down to 135°C, add water for hydrolysis for 90 minutes, then cool down to 93°C again;

[0022] Step 3: Pour 10 parts of industrial naphthalene oil into the reaction bottle, heat up to 70°C and start stirring until the temperature rises to 90°C, pour it into the reaction kettle, add 2 parts of modifier to the reaction kettle and stir until uniform;

[0023] Step 4: Drop 3 parts of f...

Embodiment 2

[0025] Embodiment 2. The present invention provides a technical solution: a method for synthesizing naphthalene-based water reducer from the residue of phthalic anhydride prepared by naphthalene method, comprising the following steps;

[0026] Step 1: Take 38 parts of phthalic anhydride residues and grind them through crushing equipment, then put the crushed phthalic anhydride residues into the reaction kettle, stir the phthalic anhydride residues, slowly drop 5 parts of concentrated sulfuric acid into the stirring process, and control the temperature at 110 minutes at 240°C;

[0027] Step 2: Cool down to 140°C, add water for hydrolysis for 95 minutes, then cool down to 90°C again;

[0028] Step 3: Pour 12 parts of industrial naphthalene oil into the reaction bottle, heat up to 80°C and start stirring until the temperature rises to 100°C, then pour it into the reaction kettle, add 4 parts of modifier to the reaction kettle and stir until uniform;

[0029] Step 4: Drop 3 part...

Embodiment 3

[0031] Embodiment 3. The present invention provides a technical solution: a method for synthesizing naphthalene-based water reducer from the residue of phthalic anhydride prepared by naphthalene method, comprising the following steps;

[0032] Step 1: Take 30 parts of phthalic anhydride residue and grind it through the crushing equipment, then put the crushed phthalic anhydride residue into the reaction kettle, stir the phthalic anhydride residue, slowly drop 4 parts of sulfamic acid in the stirring process, and control the temperature Maintain at 230°C for 110 minutes;

[0033] Step 2: Cool down to 130°C, add water for hydrolysis for 100 minutes, then cool down to 95°C again;

[0034] Step 3: Pour 11 parts of industrial naphthalene oil into the reaction bottle, heat up to 70°C and start stirring until the temperature rises to 110°C, then pour it into the reaction kettle, add 4 parts of modifier to the reaction kettle and stir until uniform;

[0035] Step 4: Add 3 parts of f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com