Straw base film with heavy metal adsorption function and preparation method thereof

A base film and heavy metal technology, applied in chemical instruments and methods, and other chemical processes, can solve the problems of waste of straw resources, limited use of heavy metal removal methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A straw-based film with a heavy metal adsorption function, the preparation method of which comprises the following steps:

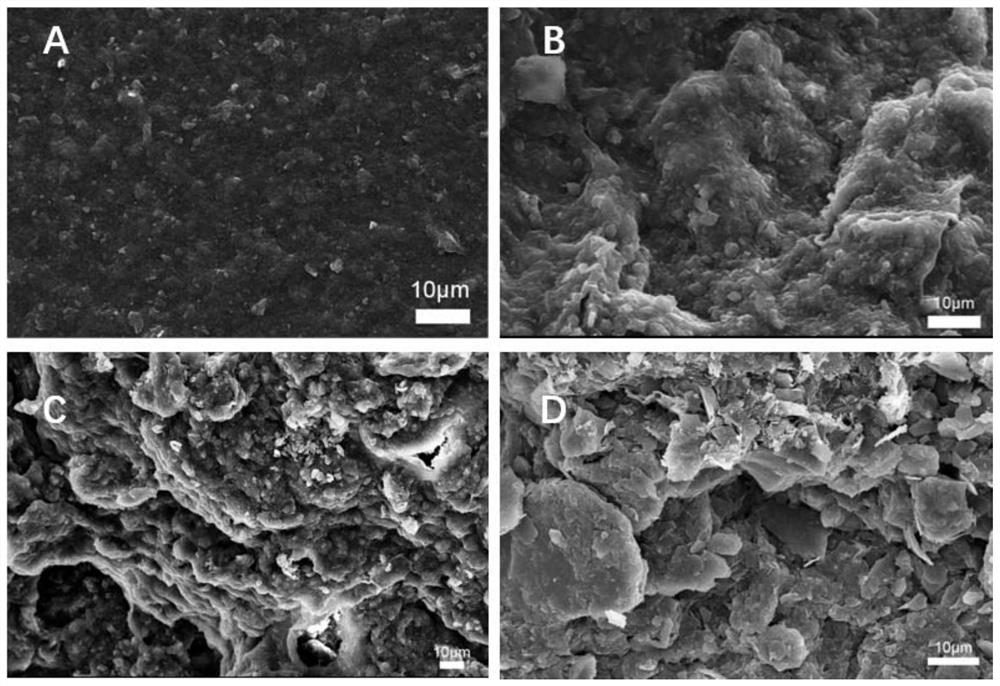

[0036] (1) Ultrasonic-assisted steam explosion pretreatment is carried out on the corn stalk raw material, and water washing is carried out to obtain a lignocellulosic material with a loose tissue structure;

[0037] (2) Add dimethyl sulfoxide solution to the lignocellulosic material, swell with planetary stirring for 0.4h, then continue to add tetrabutylammonium hydroxide solution, dimethyl sulfoxide solution and tetrabutylammonium hydroxide solution with a mass concentration of 40% The volume ratio is 2:1, planetary stirring and dissolving for 0.8h, wherein the lignocellulosic material accounts for 4% of the total mass of the dimethyl sulfoxide solution and the tetrabutylammonium hydroxide solution;

[0038] (3) The solution in step (2) is centrifuged at the speed of 8000r / min for 2min, and the supernatant is collected, then, chitosan is added in...

Embodiment 2

[0042] A straw-based film with a heavy metal adsorption function, the preparation method of which comprises the following steps:

[0043] (1) Ultrasonic-assisted steam explosion pretreatment is carried out on the corn stalk raw material, and water washing is carried out to obtain a lignocellulosic material with a loose tissue structure;

[0044] (2) Add dimethyl sulfoxide solution to the lignocellulosic material, planetary stirring and swelling for 0.8h, then continue to add tetrabutylammonium hydroxide solution, dimethylsulfoxide solution and tetrabutylammonium hydroxide solution with a mass concentration of 50% The volume ratio is 5:1, planetary stirring and dissolving for 1.5h, wherein the lignocellulosic material accounts for 7% of the total mass of the dimethyl sulfoxide solution and the tetrabutylammonium hydroxide solution;

[0045] (3) The solution in the step (2) is centrifuged at a speed of 12000r / min for 4min, and the supernatant is collected, then, chitosan is adde...

Embodiment 3

[0049] A straw-based film with a heavy metal adsorption function, the preparation method of which comprises the following steps:

[0050] (1) Ultrasonic-assisted steam explosion pretreatment is carried out on the corn stalk raw material, and water washing is carried out to obtain a lignocellulosic material with a loose tissue structure;

[0051] (2) Add dimethyl sulfoxide solution to the lignocellulosic material, planetary stirring and swelling for 0.5h, then continue to add tetrabutylammonium hydroxide solution, dimethylsulfoxide solution and tetrabutylammonium hydroxide solution with a mass concentration of 45% The volume ratio is 4:1, planetary stirring and dissolving for 1h, wherein the lignocellulosic material accounts for 5% of the total mass of the dimethyl sulfoxide solution and the tetrabutylammonium hydroxide solution;

[0052] (3) The solution in the step (2) is centrifuged at a speed of 10000r / min for 3min, and the supernatant is collected, and then, chitosan is ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com