Automatic injection dyeing machine

An automatic and automatic control system technology, applied in the field of tie-dyeing, can solve the problems of low degree of automation, high labor intensity and low production efficiency of manual injection dyeing, and achieve the effect of reducing labor consumption, high labor intensity and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] An automatic injection dyeing machine of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

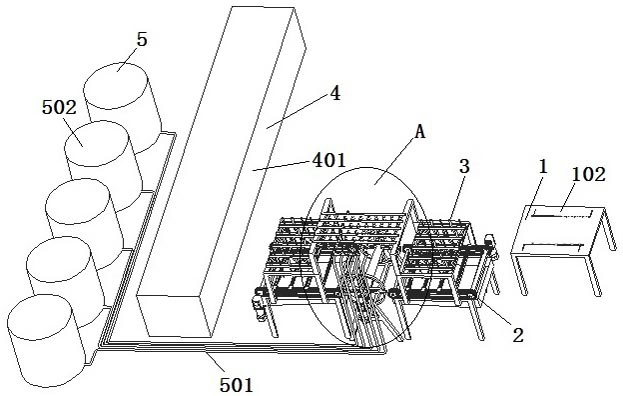

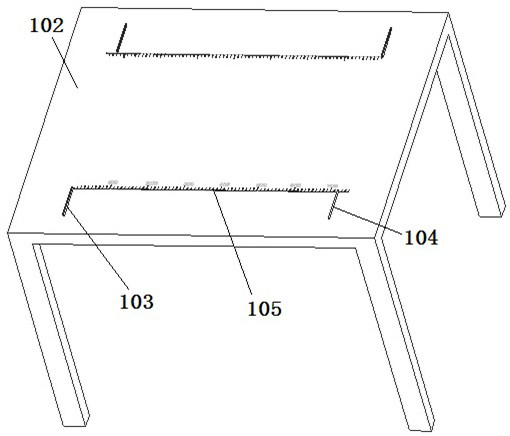

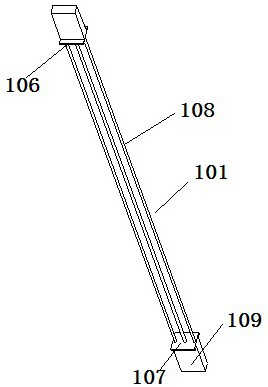

[0036] like figure 1 As shown, an automatic injection dyeing machine includes a conveying system 2, a dyeing system 3, an automatic control system, a feeding system 1, a feeding system 4, a dye supply system 5, and the like.

[0037] The conveying system 2 is responsible for conveying the clothes, including the power drive unit (namely the first motor 2022), the conveyor belt 2021, the guiding and positioning device (namely the limit slot), the turning mechanism 208, the fixed platform (namely the bottom frame 203), and related supports (such as the chair Type bracket 204) and other parts.

[0038] Dyeing system 3 completes clothing dyeing, including dye supply container (namely dye storage barrel 502) and pipeline, valve group (namely main pipe valve 2043 and solenoid valve 2045), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com