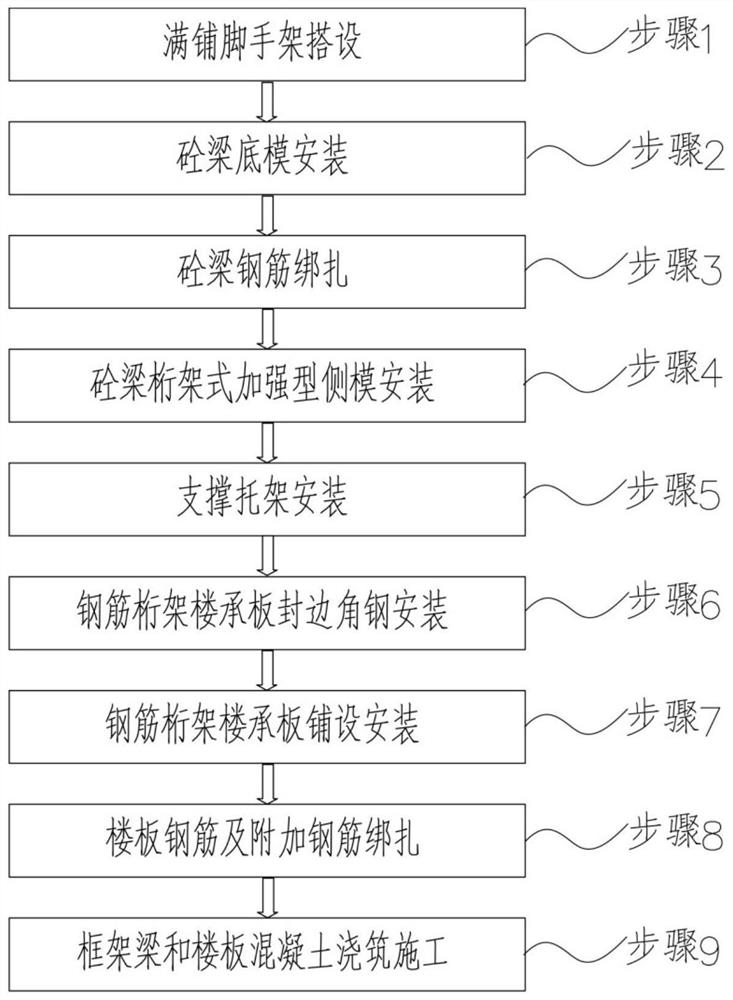

Construction method for assembling steel bar truss composite floor of reinforced concrete frame structure

A technology of reinforced concrete and reinforced concrete beams, which is applied to the on-site preparation of floor slabs, structural elements, and building components, can solve the problems of low construction efficiency, long construction period, and easy occurrence of blasting, so as to improve construction efficiency and shorten the The construction period and the effect of improving the bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

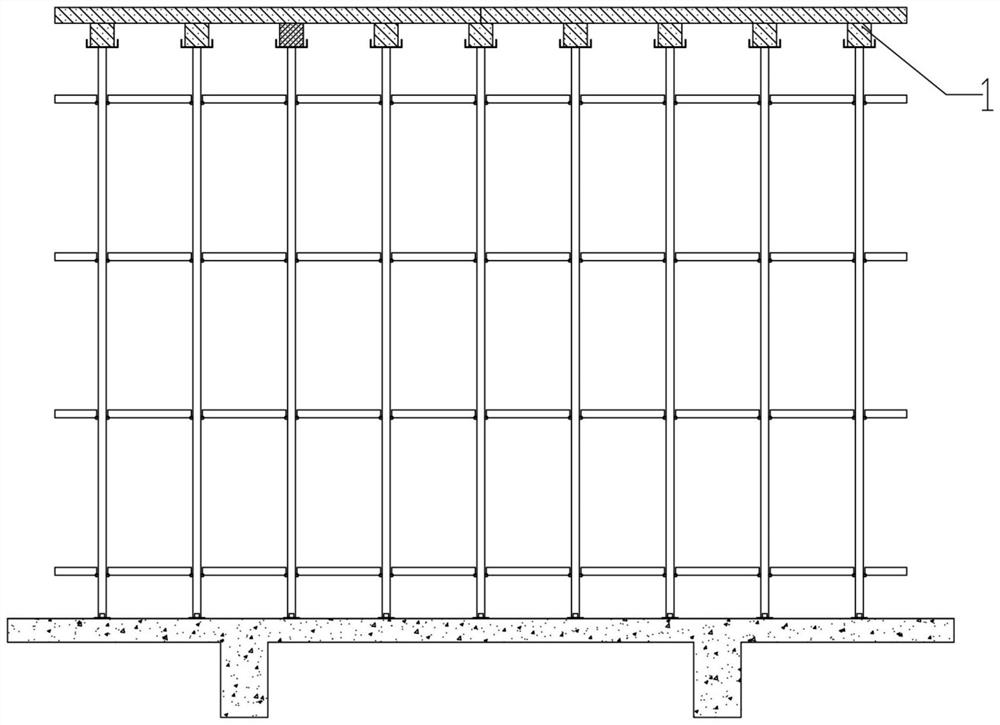

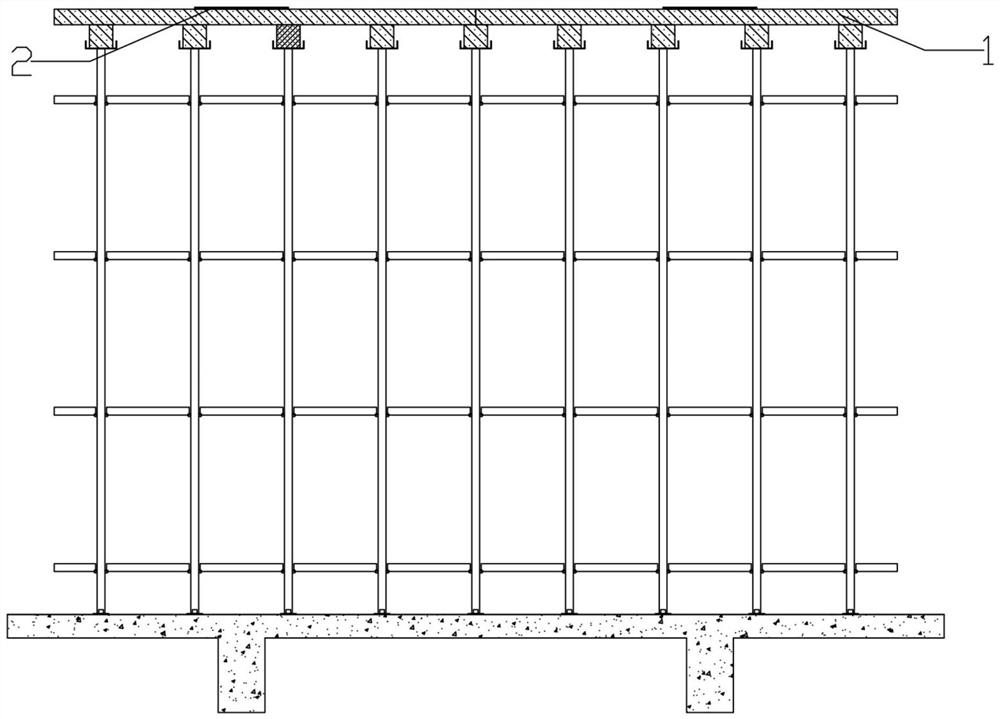

Method used

Image

Examples

Embodiment 1

[0083] like Figure 21 As shown, the steel bar truss floor deck 7 of the present invention includes a bottom formwork 71 and a steel bar truss 72, and the bottom formwork 71 and the steel bar truss 72 are welded together. 722 is still upper and lower parallel settings, and the web reinforcement 723 arranged between the upper chord reinforcement 721 and the lower chord reinforcement 722 is a non-continuous web reinforcement 723, and the purpose of being designed as a discontinuous web reinforcement 723 is to save reinforcement materials. Thereby reducing costs.

Embodiment 2

[0085] like Figure 22 As shown, the reinforced truss floor deck 7 of the present invention includes a support bar 73, and the support bar 73 includes a support transverse bar 731 and a support vertical bar 732, and the support transverse bar 731 and the support vertical bar 732 are welded together.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com