a mn 5 o 8 Nano cage oxygen reduction electrocatalyst and preparation method thereof

An electrocatalyst and nano-cage technology, which is applied in the field of Mn5O8 nano-cage oxygen reduction electrocatalyst and its preparation, can solve the problems of high consumption of noble metal Pt, high commercial cost, non-precious metal catalyst catalytic activity can not meet the requirements and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

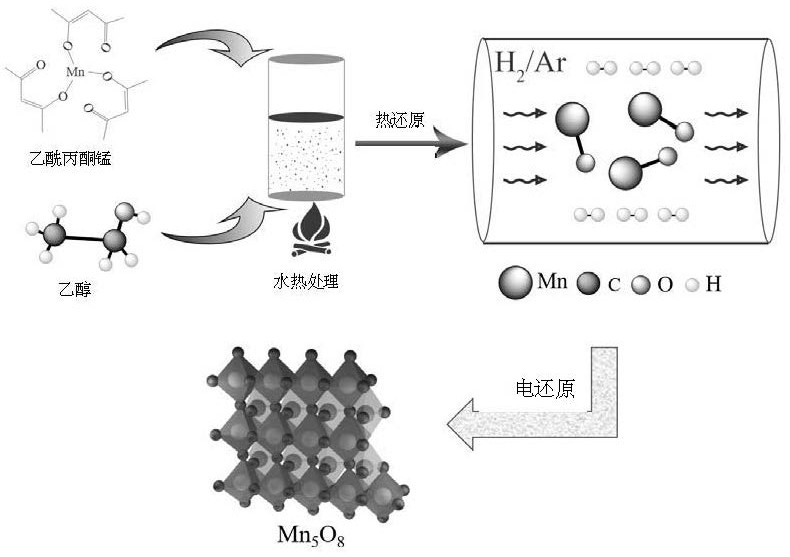

[0031] Mn 3 O 4 Preparation: Dissolve 0.5-2 mmol of manganese acetylacetonate in 20-80 mL of alcohol solution, then transfer the solution to a hydrothermal kettle, react at 100-120 ° C for 10-14 h, and then centrifuge the resulting mixture with alcohol for three times. Repeated, centrifuged with water once, and finally collected by freeze-drying for 10-24 h. The hydrothermal reaction can also be carried out under high pressure, and the pressure can be 2-20MPa.

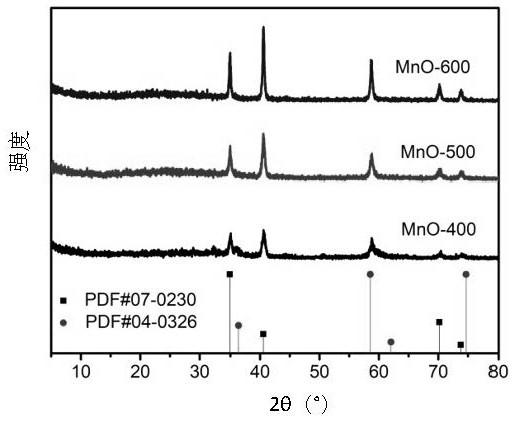

[0032] Preparation of MnO: The above-obtained samples were reacted at 400-700° C. for 1-4 hours in a reducing atmosphere. The reducing atmosphere is 5%H 2 Mixed gas with 95% Ar or 10% H 2 and 90% Ar mixture. above H 2 or Ar percentage refers to the volume ratio. The rate of temperature increase may be 2 to 5°C / min.

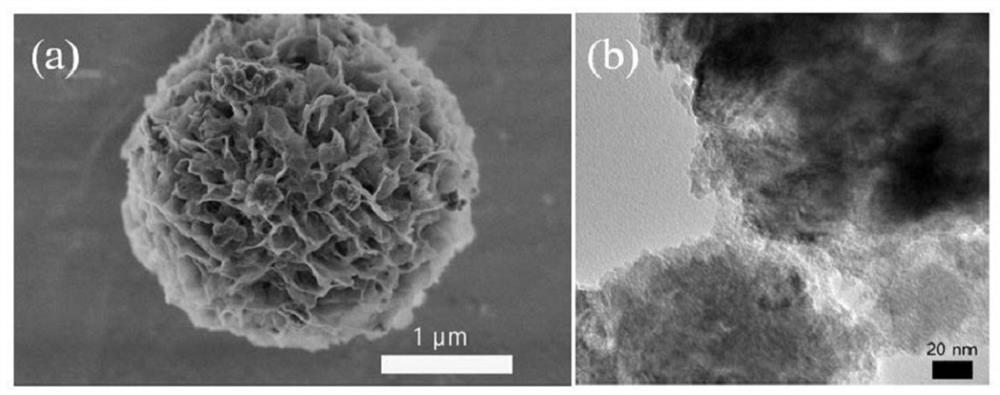

[0033] Mn 5 O 8 Preparation: Take 5 mg of the above MnO nanoflower powder and 5 mg of carbon black into a 5 mL centrifuge tube, add 90-200 μL of deionized water and 770-900 μL of isopropanol at t...

Embodiment 1

[0038] According to the above-mentioned technical scheme and technological process of the present invention, first prepare Mn 3 O 4 Nanoflower precursor materials. Weigh 1 mmol of manganese acetylacetonate and dissolve it in 40 mL of alcoholic solution, then transfer the solution to a hydrothermal kettle, react at 120 ° C for 10 h, then centrifuge the resulting mixture three times with alcohol and once with water, and finally freeze the solution. Dry for 12h and collect to obtain Mn 3 O 4 Nanoflower precursor materials.

[0039] The Mn obtained above was 3 O 4 Nanoflower precursor material at 5%H 2 The mixture was reacted with 95% Ar at 400 °C for 2 h, and the heating rate was 5 °C / min to obtain MnO nanoflower powder.

[0040] Next is Mn 5 O 8 Preparation of catalyst: 5 mg of the above MnO nanoflower powder and 5 mg of carbon black were placed in a 5 mL centrifuge tube, 190 μL of deionized water and 800 μL of isopropanol were added at the same time, sonicated for 0.5 ...

Embodiment 2

[0043] According to the process flow (same as Example 1), first prepare Mn 3 O 4 Nanoflower precursor materials. Then the Mn obtained above 3 O 4 Nanoflower precursor material at 5%H 2 React with 95% Ar at 500 °C for 2 h at a heating rate of 5 °C / min to obtain MnO nanoflower powder.

[0044] Next is Mn 5 O 8 Preparation of catalyst: 5 mg of the above MnO nanoflower powder and 5 mg of carbon black were placed in a 5 mL centrifuge tube, 120 μL of deionized water and 860 μL of isopropanol were added at the same time, sonicated for 0.5 hours, then 10 μL of Nafion solution was added, and sonicated again for 0.5 hours to obtain Suspension at a concentration of 5 mg / mL;

[0045] Take the above suspension and apply it to the surface of the glassy carbon electrode, use the glassy carbon electrode as the working electrode, the graphite rod as the counter electrode, and the Ag / AgCl as the reference electrode, correctly connect in the electrolytic cell and use the chronoamperometry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com