Method for improving appearance of continuous fiber reinforced thermoplastic composite material product

A technology to enhance thermoplastic and composite materials, applied in the direction of coating, can solve the problems of wrinkled product edges, burrs, etc., to achieve the effect of improving appearance, improving production efficiency, saving time and money investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

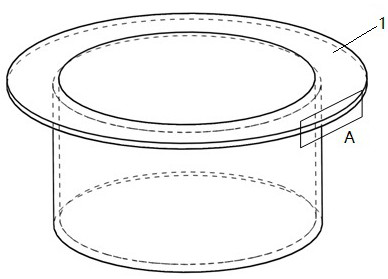

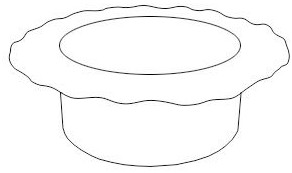

[0029] Example 1, please combine figure 1 As shown, the product involved in this embodiment is a composite material box body with flanges, and the box body part concave in the middle is stretched and formed under hot pressing. During the stretch forming process, the position of flange 1 is wrinkled due to the force in the in-plane direction, such as figure 2 shown. The specific method of improving the appearance of the folds in this embodiment is to determine the maximum height difference of the folds at the position of the flanging 1 when only the continuous fiber reinforced thermoplastic composite material 2 is used for thermocompression molding through preliminary experiments, assuming that the maximum height difference is 4mm. When designing the appearance and size of the product, please combine image 3 As shown, increase the thickness of flanging 1 so that the distance from the upper surface of flanging 1 to the highest point of the wrinkle and the distance from the l...

Embodiment 2

[0030] Example 2, please combine Figure 4 as shown, Figure 4 Shown is the edge of the part obtained by hot-pressing the pre-cut continuous carbon fiber / PP plain weave composite material sheet (hereinafter referred to as the carbon fiber / PP sheet) 4 . The carbon fiber / PP sheet 4 has a thickness of 1.5mm, and there are carbon fibers 5 sticking out at the cutting edge of the sheet. In order to remove the burr, when designing the product appearance size, an injection filling part 6 is reserved between the edge of the carbon fiber / PP sheet 4 after hot pressing and the edge of the finished product, so that the injection filling part 6 extends laterally from the carbon fiber / PP sheet 4 to The edge 7 of the finished product is provided with an injection molding cavity corresponding to the injection molding filling part 6 in the hot pressing mold formed by the carbon fiber / PP sheet 4 . During production, the carbon fiber / PP sheet 4 is heated to soften and sent into a hot-pressing m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com