Method for preparing Friedel's salt from titanium extraction slag and the Friedel's salt

A technology of titanium slag and filter residue, which is applied in the field of Friedel salt, can solve problems such as hidden dangers of environmental pollution in the surrounding area, and achieve the effects of alleviating economic pressure and environmental protection pressure, reducing pollution, and improving economic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

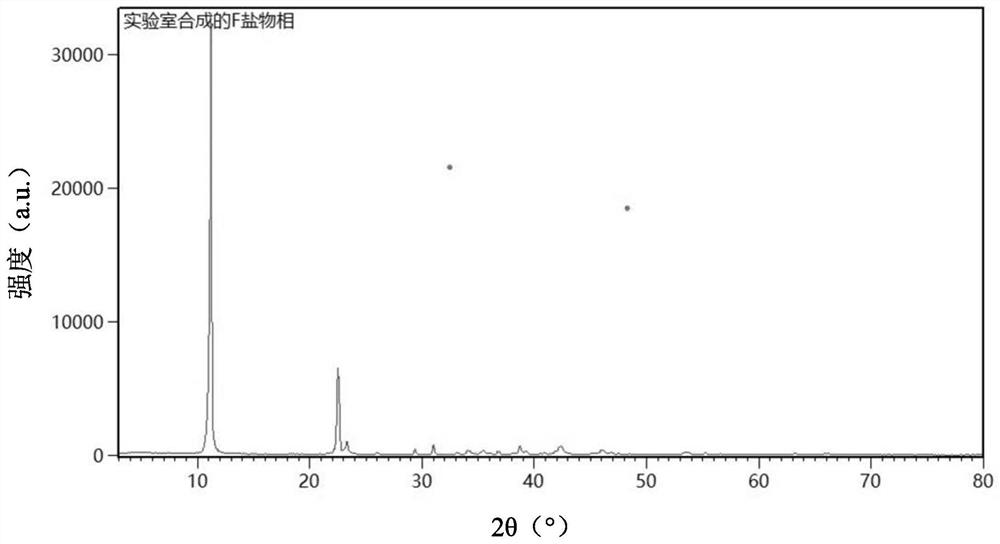

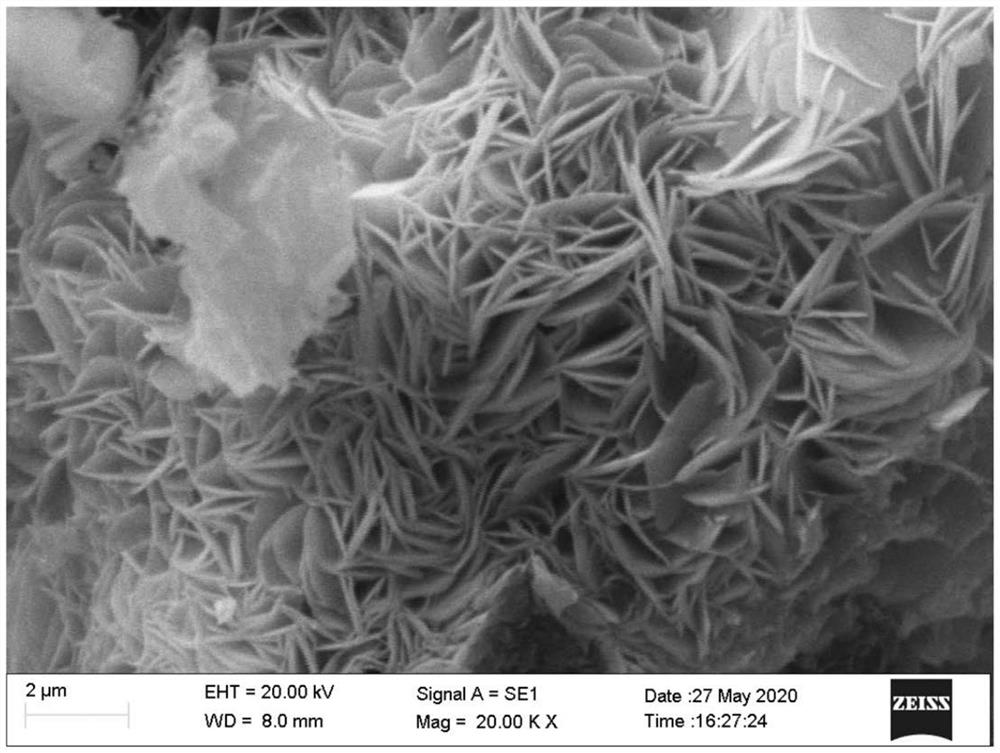

Image

Examples

example 1

[0044] In this example, the method of extracting titanium slag to prepare Friedel's salt includes:

[0045] Step S1: Take 2 t of titanium extraction slag, wash, soak and filter repeatedly until the soluble chloride ions in the filter residue are completely dissolved, and then filter to obtain the first filter residue and the first filtrate. The chlorine content in the first filter residue is 0.3‰. After drying with the waste heat generated during low-temperature chlorination of high-titanium slag, it can be directly used in cement or cement concrete admixture, and the liquid can be sold as a product.

[0046] Step S2, using the heat during low-temperature chlorination to evaporate and concentrate the first filtrate to reduce the volume of the solution. After evaporation, the concentration of calcium chloride in the filtrate is at least CaCl 2 35% of the concentration of the saturated solution, at this time the result is the first filtrate concentrate.

[0047] Step S3, measur...

example 2

[0052] In this example, the method of extracting titanium slag to prepare Friedel's salt includes:

[0053] Step S1: Take 5 t of the original titanium slag, wash, immerse in water and filter repeatedly until the soluble chloride ions in the filter residue are completely dissolved, and then filter to obtain the first filter residue and the first filtrate. At this time, the chlorine content in the first filter residue is 0.4‰, and it can be directly used in cement or cement concrete admixture, or sold as a product after being dried with waste heat generated during low-temperature chlorination of high-titanium slag.

[0054] Step S2, using the heat during low-temperature chlorination to evaporate and concentrate the first filtrate to reduce the volume of the solution. After evaporation, the concentration of calcium chloride in the filtrate is at least CaCl 2 20% of the concentration of the saturated solution, at this time the result is the first filtrate concentrate.

[0055] St...

example 3

[0060] In this example, the method for preparing Friedel's salt from titanium slag includes:

[0061] Step S1, taking 1 ton of the original titanium slag, washing, immersing and filtering repeatedly until the soluble chloride ions in the filter residue are completely dissolved. Filtration to obtain the first filter residue and the first filtrate.

[0062] The chlorine content in the first filter residue is 0.2‰. After drying with the waste heat generated during low-temperature chlorination of high-titanium residue, it can be directly used in cement or cement concrete admixture, and the liquid can be sold as a product.

[0063] Step S2, using the heat during low-temperature chlorination to evaporate and concentrate the first filtrate to reduce the volume of the solution. After evaporation, the concentration of calcium chloride in the filtrate is at least CaCl 2 25% of the concentration of the saturated solution, at this time the result is the first filtrate concentrate.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com