Fencing cloth and preparation method thereof

A technology of fencing cloth and polyester fiber, which is applied in textiles, fabrics, textiles and papermaking, etc., can solve problems such as easy oxidation, and achieve excellent electrical conductivity, excellent oxidation resistance, and no obvious color change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

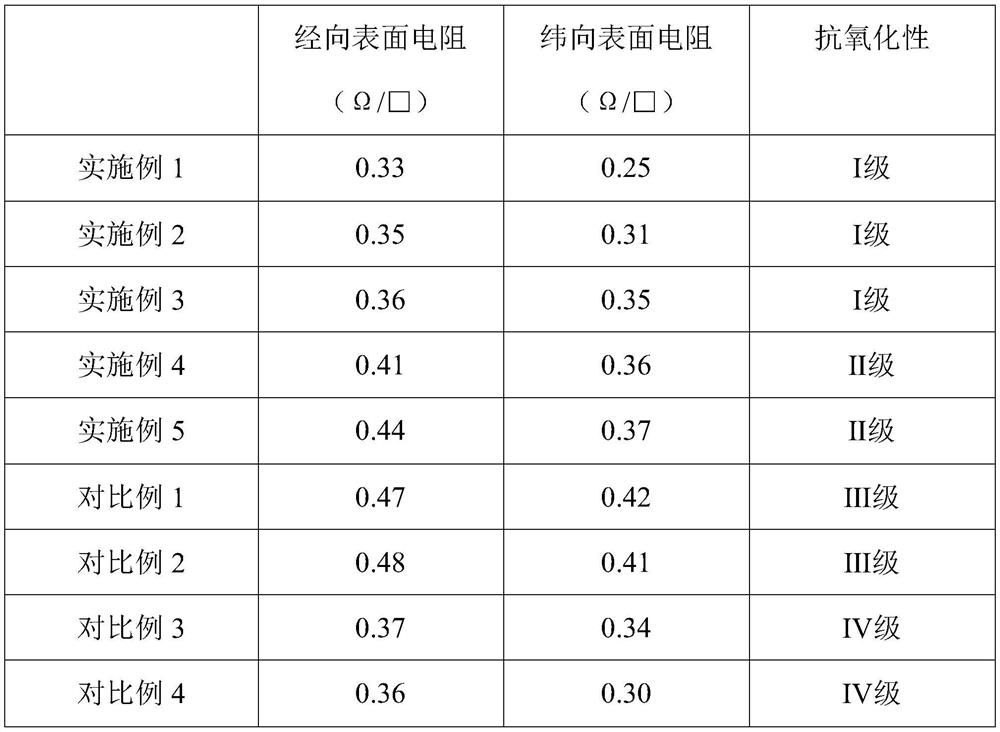

Examples

Embodiment 1

[0037] This embodiment provides a fencing cloth, which is woven from nickel wire yarns and polyester fiber filaments with a wire number ratio of 1:1.2.

[0038] (1) Polyester filament:

[0039] The raw materials for the preparation of the polyester filaments are composed of the following components in parts by weight: 100 parts of polyethylene terephthalate, 2 parts of carbon fiber, 2 parts of nanocellulose, 3 parts of silicon carbide, polyethylene oxide 4 parts.

[0041] The polyester fiber filament is divided into a first polyester fiber filament and a second polyester fiber filament;

[0042] The nickel wire yarn is formed by weaving pure nickel conductive wire and the first polyester fiber filament;

[0043] The number ratio of the pure nickel conductive wire to the first polyester fiber filament is 3:1, and the diameter of the nickel wire yarn is 0.1 mm.

[0044] (3) Fencing cloth:

[0045] The fencing cloth is composed of nickel yarns and se...

Embodiment 2

[0051] This embodiment provides a fencing cloth, which is woven from nickel yarns and polyester filaments at a ratio of 1:1.

[0052] (1) Polyester filament:

[0053] The raw materials for the preparation of the polyester filaments consist of the following components in parts by weight: 100 parts of polyethylene terephthalate (purchased from Shenzhen Yanhua Trading Co., Ltd.), 1 part of carbon fiber, nanocellulose 2 parts, 2 parts of silicon carbide, 3 parts of polyethylene oxide (purchased from Aladdin, the brand is P101344).

[0054] (2) Nickel yarn

[0055] The polyester fiber filament is divided into a first polyester fiber filament and a second polyester fiber filament;

[0056] The nickel wire yarn is formed by weaving pure nickel conductive wire and the first polyester fiber filament;

[0057] The number ratio of the pure nickel conductive filament to the first polyester filament is 2:1, and the diameter of the nickel filament yarn is 0.07mm.

[0058] (3) Fencing cl...

Embodiment 3

[0062] This embodiment provides a fencing cloth, which is woven from nickel wire yarns and polyester fiber filaments with a wire number ratio of 1:1.5.

[0063] (1) Polyester filament:

[0064] The raw materials for the preparation of the polyester filaments consist of the following components in parts by weight: 100 parts of polyethylene terephthalate, 4 parts of carbon fiber, 2 parts of nanocellulose, 4 parts of silicon carbide, polyethylene oxide 5 servings.

[0065] (2) Nickel yarn

[0066] The polyester fiber filament is divided into a first polyester fiber filament and a second polyester fiber filament;

[0067] The nickel wire yarn is formed by weaving pure nickel conductive wire and the first polyester fiber filament;

[0068] The number ratio of the pure nickel conductive filament to the first polyester filament is 4:1, and the diameter of the nickel filament yarn is 0.12mm.

[0069] (3) Fencing cloth:

[0070] The fencing cloth is composed of nickel yarns and se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com