Lithium secondary battery including negative electrode having improved resistance to degradation, and method for manufacturing same

A lithium secondary battery and negative electrode technology, which is applied in the field of lithium secondary battery and its manufacturing, can solve the problems of poor performance of lithium secondary battery and limit the realization of secondary battery, and achieve the effect of preventing volume expansion and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0076] Wherein the preparation of the negative electrode includes: covering the position adjacent to the extension line of the boundary line between the negative electrode current collector part and the negative electrode tab part when observing the negative electrode from above; coating the negative electrode active material slurry on the negative electrode current collector part and drying ; and unmasking.

[0077] In the case of the method of manufacturing a lithium secondary battery according to the present invention, it is possible to manufacture a lithium secondary battery by a simpler method, which includes obtaining the advantage in preventing deterioration caused at the time of charging and discharging of the lithium secondary battery. Improved anode with excellent lifetime characteristics.

[0078] In this case, in addition to preparing the negative electrode, a method of manufacturing a lithium secondary battery known in the art may be employed.

[0079] In the met...

Embodiment 1

[0136]

[0137] SiO x (050 ): 5μm to 10μm) and artificial graphite (average particle size (D 50 ): 10 μm to 15 μm) negative electrode active material mixed with each other at a weight ratio of 2:8, binder with styrene-butadiene rubber and carboxymethyl cellulose mixed with each other at a weight ratio of 2:3, and carbon nanotubes (CNT) Disperse conductive substances. The content of silicon in the negative electrode active material was 11.4% by weight.

[0138] The prepared negative active material, binder, and conductive material were mixed with each other in a weight ratio of 94:5:1, and then dispersed in water to prepare negative active material slurry.

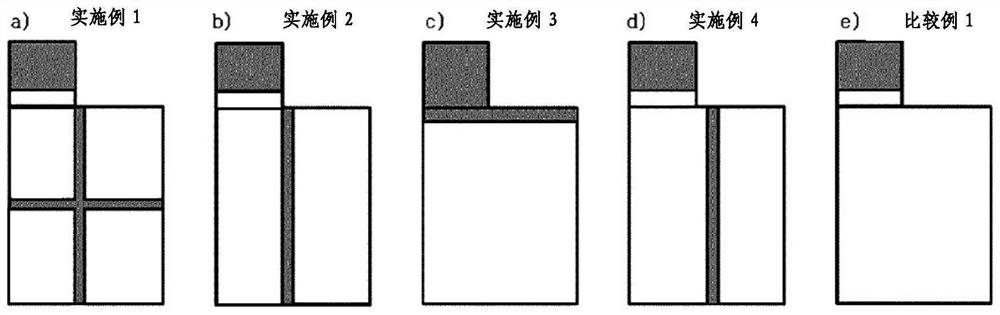

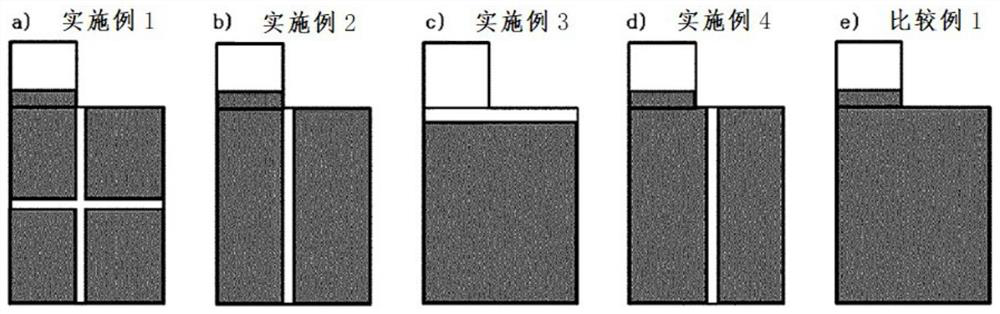

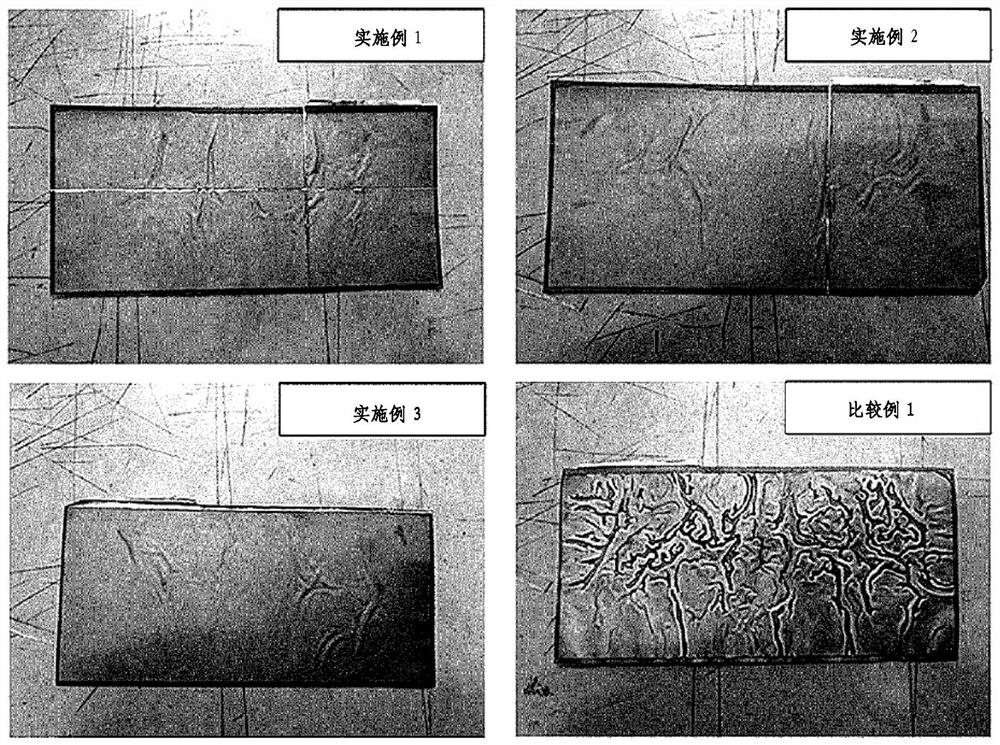

[0139] A copper film (width: 200 mm, length: 100 mm, thickness: 10 µm, except for the protruding part) was edged with a cast polypropylene (CPP) tape (available from Tapex Co., Ltd., width: 2 mm, thickness: 50 µm). ) as figure 1 Tape and mask the shape shown in a.

[0140] The negative electrode active material slurr...

Embodiment 2

[0150] except through the figure 1 The shape of b is manufactured by taping a copper film coated with a figure 2 Except for the negative electrode of the negative electrode active material having the shape of b, the same procedure as in Example 1 was carried out.

[0151] The produced lithium secondary batteries were evaluated according to the above-mentioned evaluation methods.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com