Cf/C-SiC composite material for engine piston and preparation method thereof

A composite material and engine technology, applied in engine components, machines/engines, pistons, etc., can solve the problems of reducing the reliability of the mechanical properties of materials at room temperature, increasing the sensitivity of materials to crack damage, and limiting applications, so as to improve service reliability. , reduce the sensitivity of crack damage, and promote the effect of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

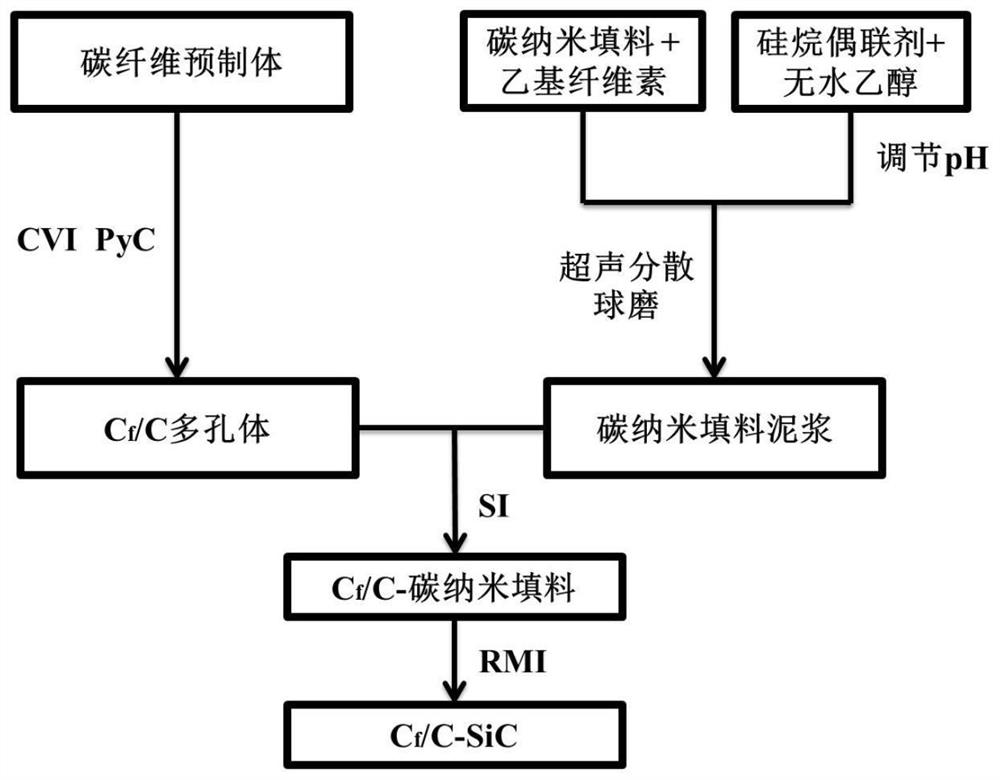

Method used

Image

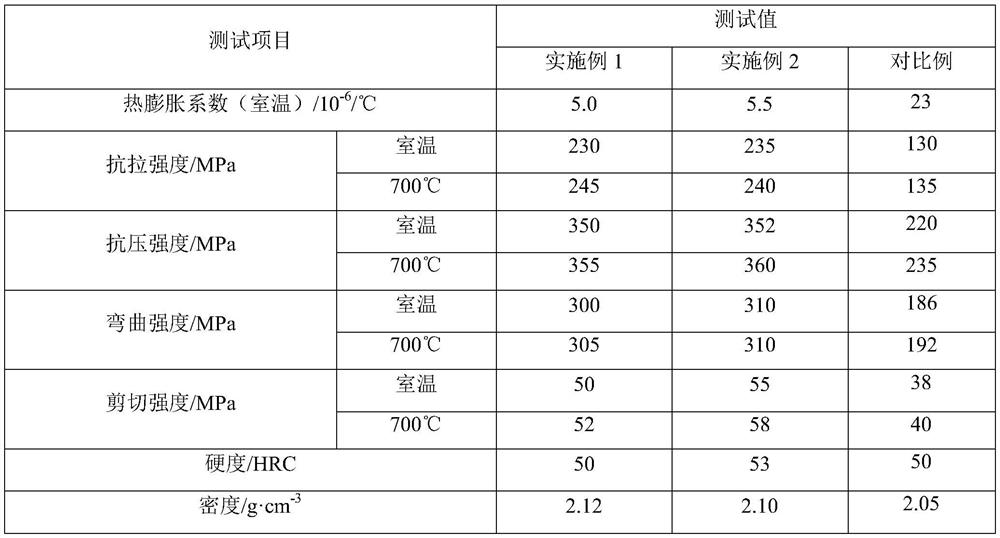

Examples

Embodiment 1

[0036] (1) The density is 0.35g / cm prepared by the relay acupuncture method 3 carbon fiber prefabricated body;

[0037] (2) Pyrolytic carbon densification of carbon fiber prefabricated body by fast CVI method, and the obtained density is 1.35g / cm 3 C f / C porous body. Among them, the carbon source gas for chemical vapor deposition is propane and natural gas, the diluent gas is nitrogen, the volume ratio of propane:natural gas:nitrogen is 1:5:8, the infiltration time is 150h, the infiltration temperature is 980°C, and the pressure is 2000Pa , the residence time is 1.8s;

[0038] (3) The prepared C f The / C porous body is heat-treated at a high temperature of 2400 ° C for 2 hours, the argon gas protection atmosphere, and the pressure of 1500 Pa, the purpose is to improve the low-density C f / C The degree of graphitization of the porous body removes non-carbon impurities in the porous body;

[0039] (4) Add 6g of absolute ethanol and 1g of silane coupling agent A-1230 into ...

Embodiment 2

[0044] (1) The density is 0.40g / cm prepared by relay acupuncture method 3 carbon fiber prefabricated body;

[0045] (2) Pyrolytic carbon densification of carbon fiber prefabricated body by fast CVI method, and the obtained density is 1.25g / cm 3 C f / C porous body. Among them, the carbon source gas for chemical vapor infiltration is propane, the diluent gas is nitrogen, the volume ratio of source gas and diluent gas is 1:10, the infiltration time is 200h, the infiltration temperature is 1050°C, the pressure is 2500Pa; the residence time is 1.3 s.

[0046] (3) The prepared C f The / C porous body is heat-treated at a high temperature of 2200°C for 2h, under the protective atmosphere of argon gas, and the pressure is 1500Pa, the purpose is to improve the low-density C f / C The degree of graphitization of the porous body removes non-carbon impurities in the pores;

[0047] (4) Add 8g of absolute ethanol and 1.2g of silane coupling agent A-1230 into a beaker and mix them, then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com