Full-automatic glass tube iron wire strapping machine

A glass tube and strapping machine technology, which is applied to the parts of strapping machinery, strapping materials, packaging automatic control, etc., can solve the problems of manpower and material resources for strapping glass tubes, low added value of glass tubes, and sharp edge damage. Achieve the effects of reducing labor intensity, light weight and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings. It should be noted that this embodiment is based on the technical solution, and provides detailed implementation and specific operation process, but the protection scope of the present invention is not limited to the present invention. Example.

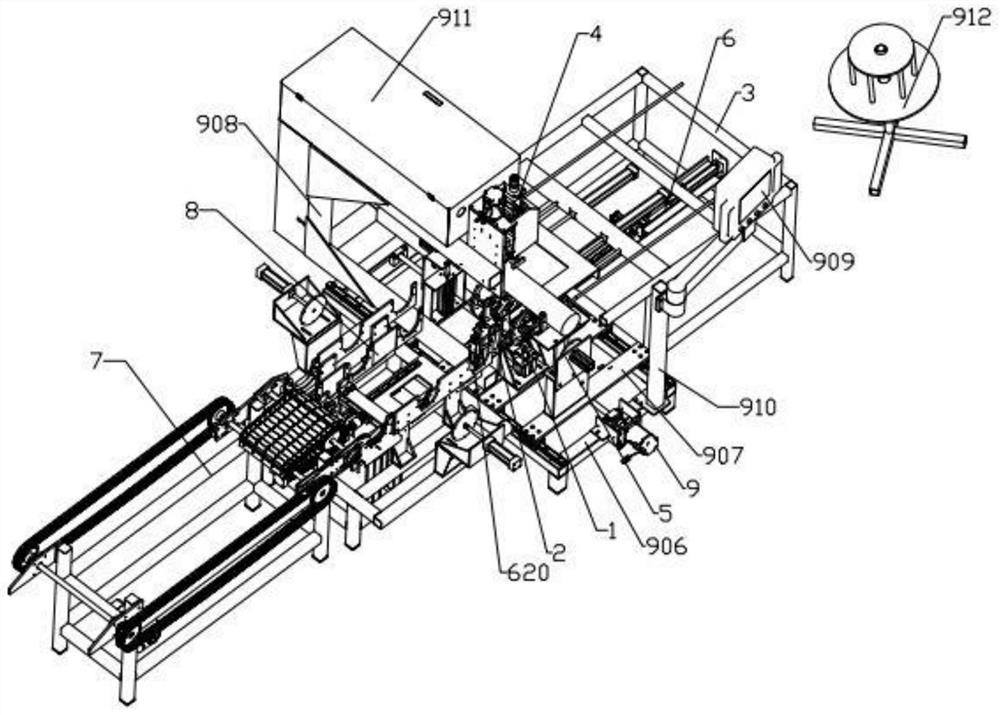

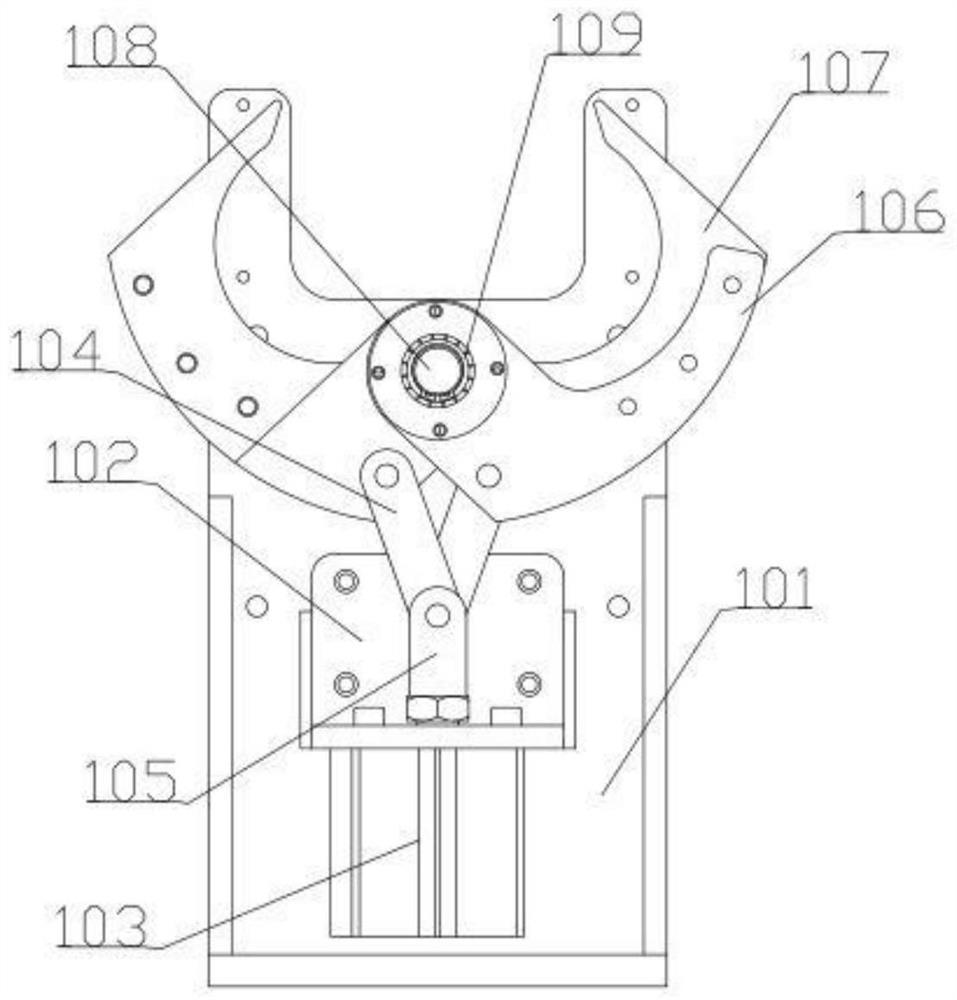

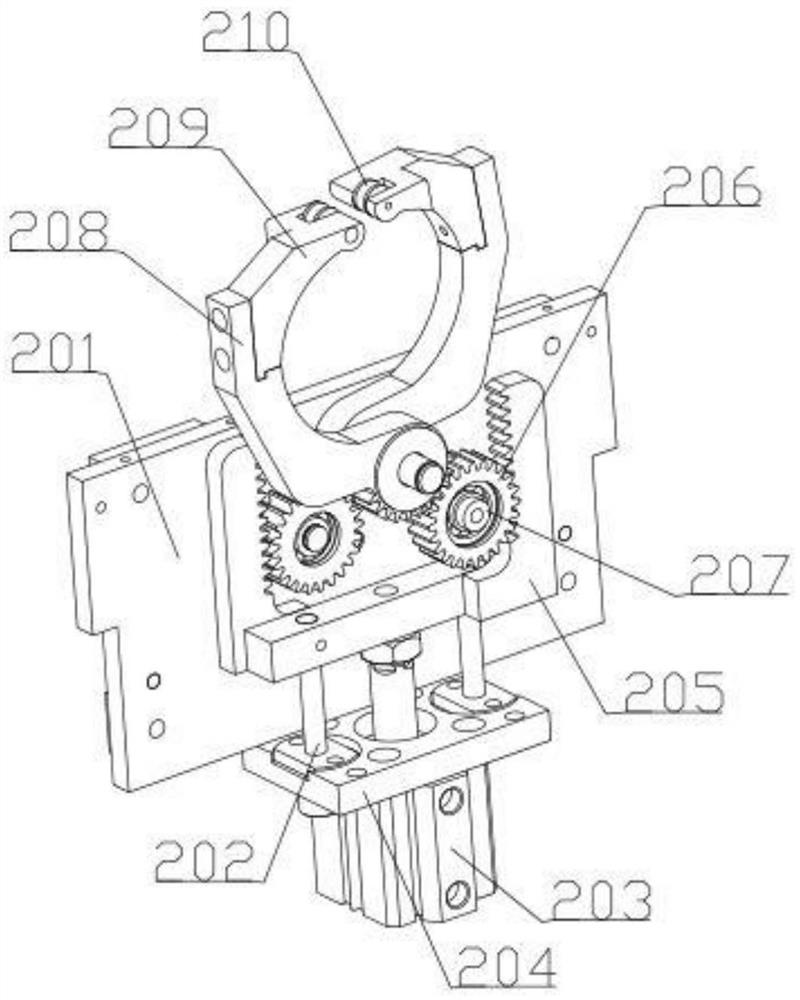

[0028] A fully automatic glass tube iron wire binding machine, characterized in that: a fully automatic glass tube iron wire binding machine, the body is sequentially provided with a chain feeding system 7, a feeding system 8, a wire feeding and cutting system 6, and a base along the workpiece transmission direction Sliding table system 9 and blanking system 3, on the base sliding table system 9, screw moving system, alignment system, tube holding system 1, wire holding system 2, and wire twisting system 4 are arranged in sequence parallel to the direction of the workpiece. The wire holding system 4 is located directly above the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com