Two-dimensional reinforced hydraulic cementing material based on granite stone powder

A technology for granite rock powder and hydraulic cementation, which is applied in cement production and other directions, can solve the problems of low utilization rate of granite rock powder, insufficient cement and fly ash resources, and resource shortage, so as to control the structural growth of cement hydration products and facilitate the Grinding process, the effect of suppressing crack growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

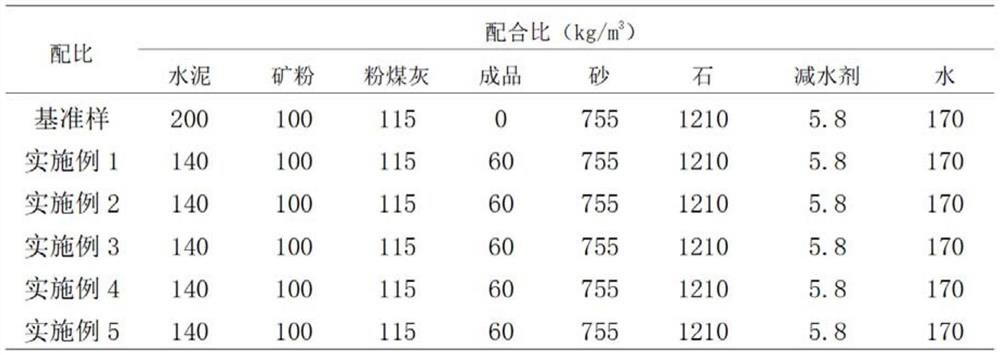

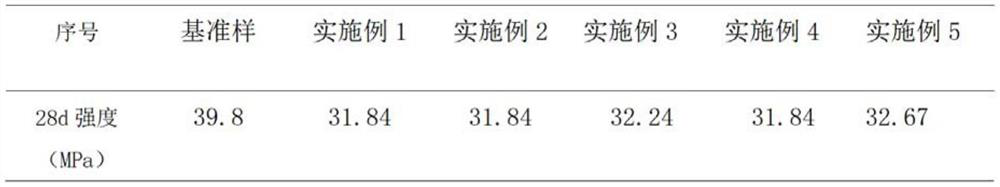

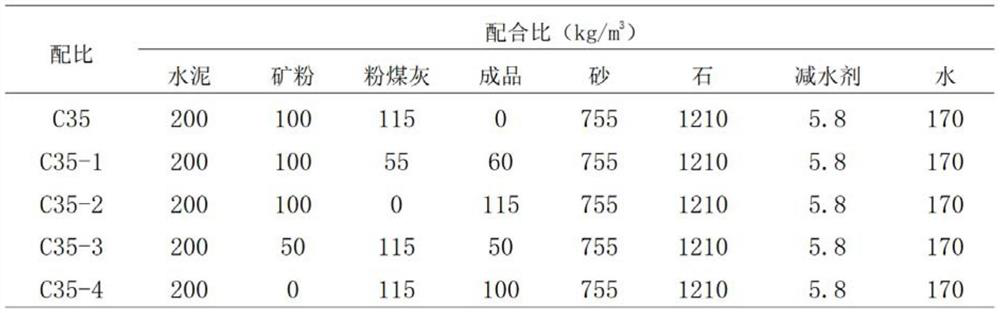

Embodiment 1

[0019] This embodiment provides a two-dimensional reinforced hydraulic cementitious material based on granite stone powder, which is prepared by the following steps:

[0020] (1), each raw material is weighed according to the following proportions, each raw material and its mass parts are: 45 parts of granite stone powder, 25 parts of bottom slag, 7 parts of cement clinker, 2 parts of desulfurized gypsum, 1 part of calcium hydroxide, water glass 1 part, 1 part of sodium hydroxide, 0.03 part of graphene, and graphene is selected from single-layer graphene;

[0021] (2), the granite stone powder and furnace bottom slag are ground respectively and sieved with a 100 mesh screen until 3% of the granite stone powder is sieved, and 5% of the furnace bottom slag powder is sieved, and the sieved granite stone powder and furnace bottom The slag is mixed evenly with sodium hydroxide and water glass to obtain a mixture A, and the water content of the mixture A is 30%;

[0022] (3), singl...

Embodiment 2

[0026] This embodiment provides a two-dimensional reinforced hydraulic cementitious material based on granite stone powder, which is prepared by the following steps:

[0027] (1), each raw material is weighed according to the following proportions, each raw material and its mass parts are: 45 parts of granite stone powder, 35 parts of bottom slag, 10 parts of cement clinker, 3 parts of desulfurized gypsum, 2 parts of calcium hydroxide, water glass 2 parts, 3 parts of sodium hydroxide, 0.04 part of graphene, graphene selects double-layer graphene;

[0028] (2), respectively grind granite stone powder and furnace bottom slag and sieve with 200 mesh screens until 3% of the granite stone powder is sieved, and 5% of the furnace bottom slag powder is screened, and the sieved granite stone powder and furnace bottom The slag is stirred and mixed with sodium hydroxide and water glass to obtain a mixture A, and the water content of the mixture A is 30%;

[0029] (3), double-layer graph...

Embodiment 3

[0033] This embodiment provides a two-dimensional reinforced hydraulic cementitious material based on granite stone powder, which is prepared by the following steps:

[0034] (1), each raw material is weighed according to the following proportions, each raw material and its mass parts are: 50 parts of granite stone powder, 30 parts of furnace bottom slag, 11 parts of cement clinker, 3 parts of desulfurized gypsum, 1 part of calcium hydroxide, water glass 2 parts, 3 parts of sodium hydroxide, 0.03 part of graphene, graphene selects few-layer graphene;

[0035] (2), the granite stone powder and furnace bottom slag are ground respectively and sieved with a 200 mesh screen until 4% of the granite stone powder is sieved, and 8% of the furnace bottom slag powder is sieved, and the sieved granite stone powder and furnace bottom The slag is mixed evenly with sodium hydroxide and water glass to obtain a mixture A, and the water content of the mixture A is 35%;

[0036] (3), the few-la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com