Transparent silica gel strip

A silicone strip, transparent technology, used in adhesives, film/sheet release coatings, film/sheet adhesives, etc., can solve the difficulty of sealing strip installation, environmentally friendly plasticizers, easy to age and brittle, etc. problems, to achieve outstanding economic benefits, meet functional requirements, and facilitate disassembly and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

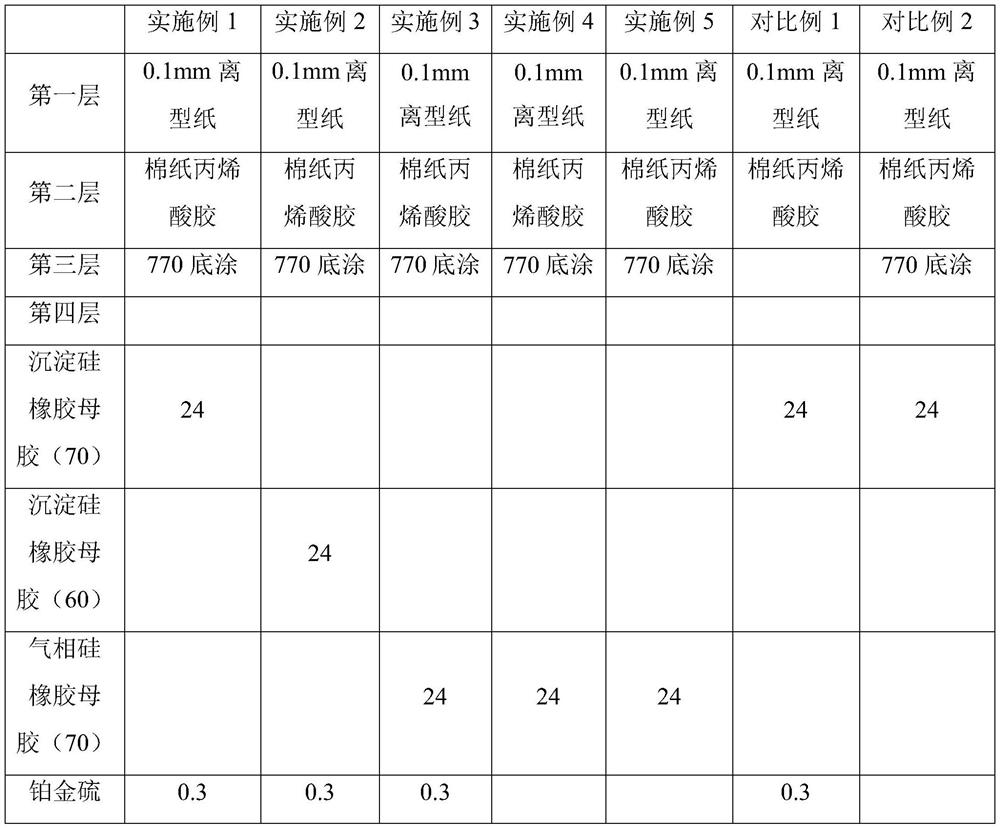

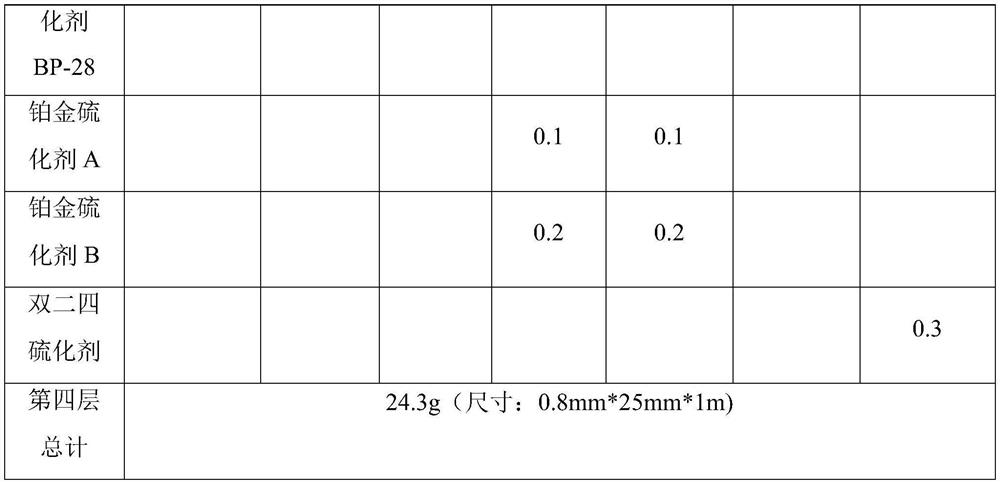

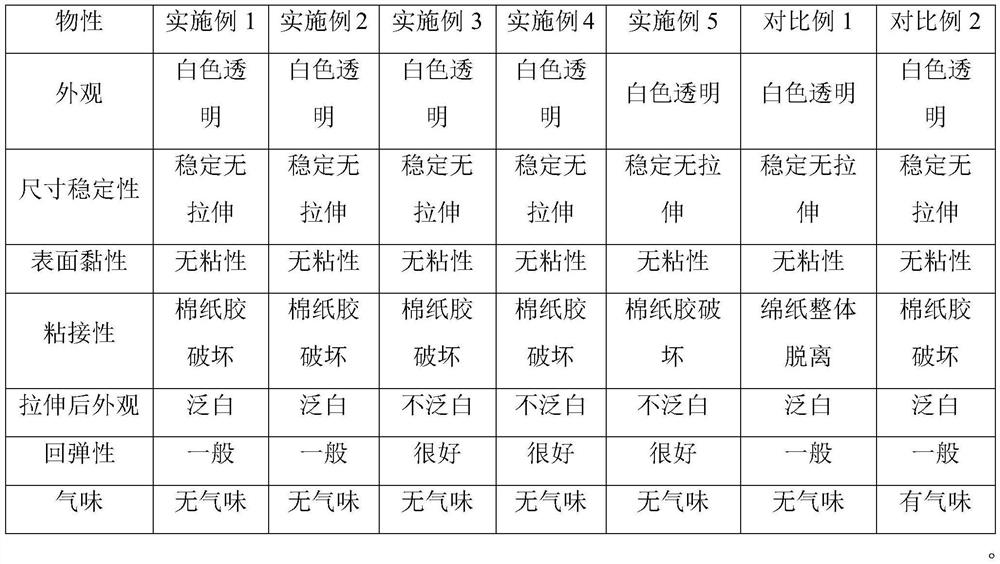

Embodiment 1

[0028] The silicone sealing strip of the present invention comprises 4 layers:

[0029] The first layer: release paper with a thickness of 0.1mm; the second layer: acrylic glue on tissue paper with a thickness of 0.3mm; the third layer: 770 primer with a glue amount of 0.1mm; the fourth layer: including 70-degree precipitated silicon Rubber masterbatch (24 parts by weight / m) and platinum vulcanizing agent BP-28 (0.3 parts by weight / m).

[0030] Use an open mill (with cooling function) to process 70-degree precipitated silicone rubber masterbatch, process 10-20kg of the masterbatch each time, first adjust the roller distance to about 10mm, feed, and add platinum vulcanizing agent BP-28 after 5 thin passes , continue to thin pass 5 times, the sheet is cooled, added to the extruder, extruded 0.8mm thin sheet and different width specifications, and vulcanized through a 20m drying tunnel (temperature 200-300°C) (specifically, the vulcanization temperature is 200°C in the first stag...

Embodiment 2

[0032] The silicone sealing strip of the present invention comprises 4 layers:

[0033] The first layer: release paper with a thickness of 0.1mm; the second layer: acrylic glue on tissue paper with a thickness of 0.3mm; the third layer: 770 primer with a glue amount of 0.1mm; the fourth layer: including 60-degree precipitated silicon Rubber masterbatch (24 parts by weight / m) and platinum vulcanizing agent BP-28 (0.3 parts by weight / m).

[0034] Use an open mill (with cooling function) to process 60-degree precipitated silicone rubber masterbatch, process 10-20kg of the masterbatch each time, first adjust the roller distance to about 10mm, feed the material, and add platinum vulcanizing agent BP-28 after 5 thin passes , continue to thin pass 5 times, the sheet is cooled, added to the extruder, extruded 0.8mm thin sheet and different width specifications, and vulcanized through a 20m drying tunnel (temperature 200-300°C) (specifically, the vulcanization temperature is 200°C in t...

Embodiment 3

[0036] The silicone sealing strip of the present invention comprises 4 layers:

[0037] The first layer: 0.1mm release paper; the second layer: cotton paper acrylic glue; the third layer: 770 primer with a glue amount of 0.1mm; the fourth layer: including 70-degree gas-phase silicone rubber masterbatch (24 weight parts / m) and platinum vulcanizing agent BP-28 (0.3 parts by weight / m).

[0038] Use an open mill (with cooling function) to process 70-degree gas-phase silicone rubber masterbatch, process 10-20kg of the masterbatch each time, first adjust the roller distance to about 10mm, feed, and add platinum vulcanizing agent BP-28 after 5 thin passes , continue to thin pass 5 times, the sheet is cooled, added to the extruder, extruded 0.8mm thin sheet and different width specifications, and vulcanized through a 20m drying tunnel (temperature 200-300°C) (specifically, the vulcanization temperature is 200°C in the first stage; the vulcanization temperature 2 stages of 250°C; vulc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com