Novel heat pipe type liquid cooling cold plate

A liquid-cooled cold plate and heat pipe technology, applied in indirect heat exchangers, lighting and heating equipment, electrical components, etc., can solve problems such as design stranding, improve service life, improve heat uniformity, and save computing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

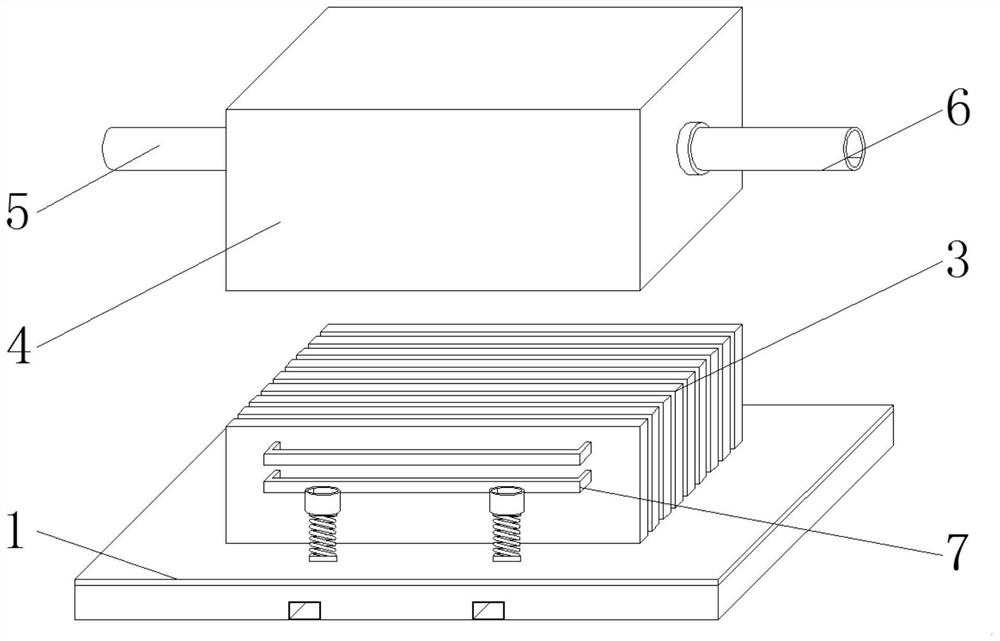

[0018] Such as figure 1 As shown, the present invention provides a technical solution: a novel heat pipe type liquid-cooled cold plate, including a base evaporation chamber 1, a plurality of fins 3 are fixedly connected to the upper surface of the base evaporation chamber 1, and the frontmost fin 3 The front surface is fixedly connected with a plurality of heat pipes 7, the rear ends of the heat pipes 7 run through a plurality of fins 3, and communicate with the base evaporation chamber 1, the base evaporation chamber 1 is provided with a cold plate cover 4, and the left side of the cold plate cover 4 The water inlet pipe 5 and the water outlet pipe 6 are respectively connected to the side and the right side. The base evaporation chamber 1 can use either copper nickel-plated heat pipes or aluminum heat pipes. The fins 3 are made of aluminum, and an aluminum cold plate cover 4 is welded on the outside. , the water inlet pipe 5 and the water outlet pipe 6 can keep the tank desig...

Embodiment 2

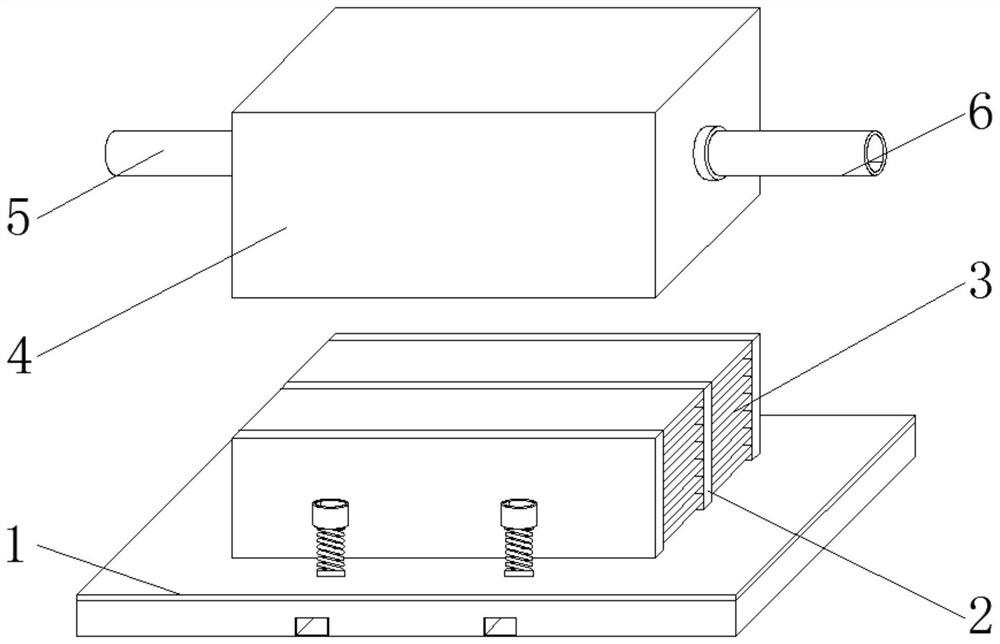

[0020] Such as figure 2 As shown, the present invention provides a technical solution: a novel heat pipe type liquid-cooled cold plate, including a base evaporation chamber 1, the upper surface of the base evaporation chamber 1 is fixedly connected with a plurality of evaporation chamber vertical pipes 2, and the evaporation chamber vertical pipes 2 The bottom of the base is connected to the inside of the base evaporation chamber 1, and a plurality of fins 3 are fixedly connected between two adjacent evaporation chamber vertical pipes 2. A cold plate cover 4 is provided above the base evaporation chamber 1, and a cold plate cover 4 The left side and the right side are respectively connected with the water inlet pipe 5 and the water outlet pipe 6. The heat source of the base evaporation chamber 1 uses the latent heat of boiling and vaporization of the working fluid to quickly transfer the heat to the vertical pipe 2 of the three-dimensional evaporation chamber, and then the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com