Thermal management control method and system and fuel cell vehicle

A control system and control method technology, applied in the direction of power system fuel cells, fuel cells, fuel cell additives, etc., can solve the problems of impractical thermal management control methods and systems, large workload of cooling fans, low energy utilization, etc. , to optimize the configuration of the thermal management control system, improve the level of thermal management, and ensure efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

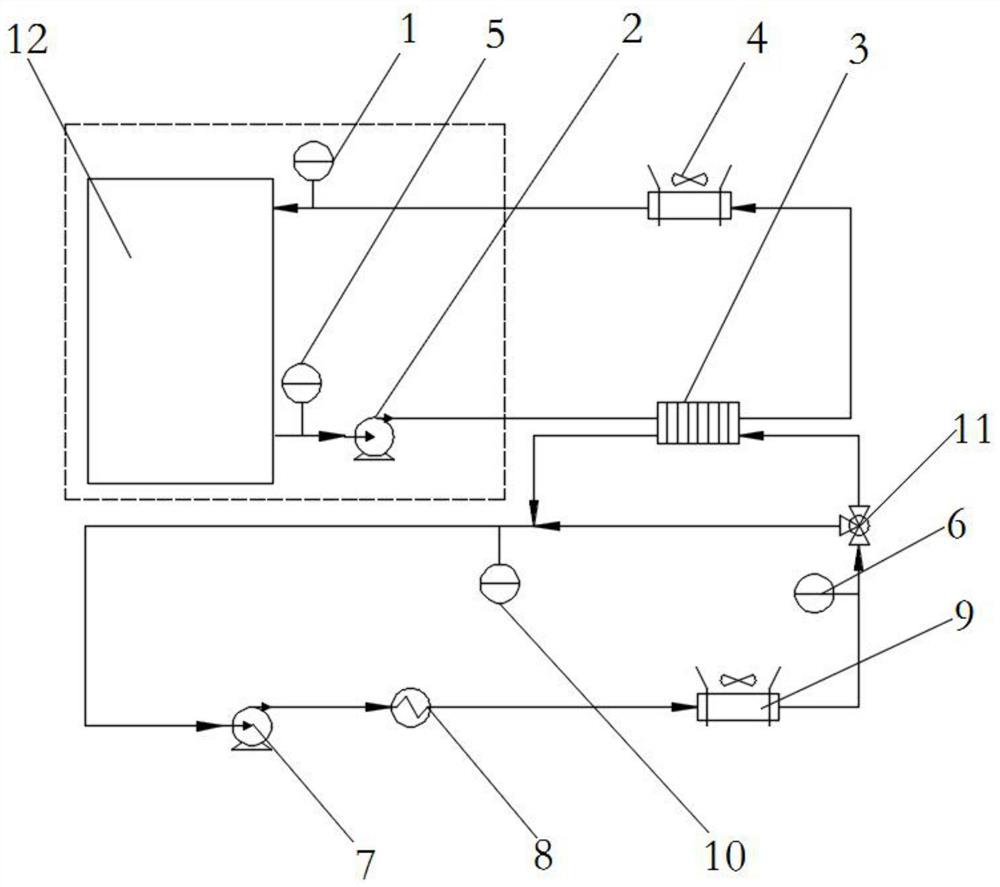

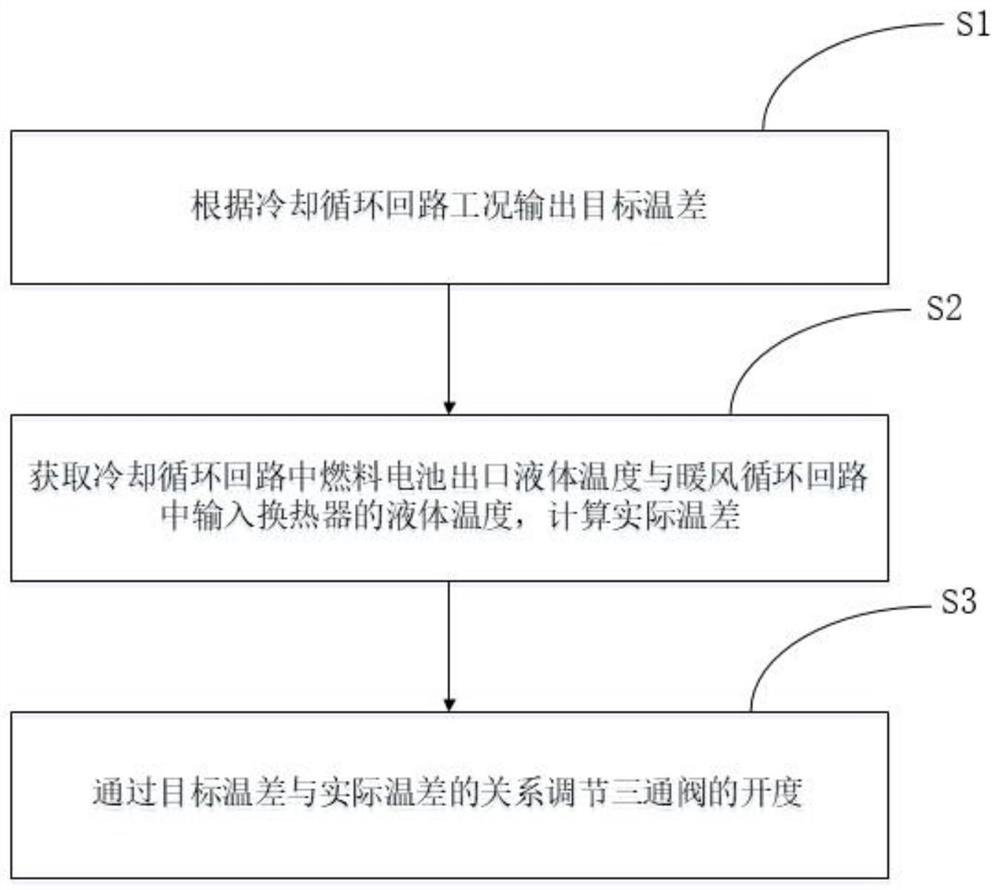

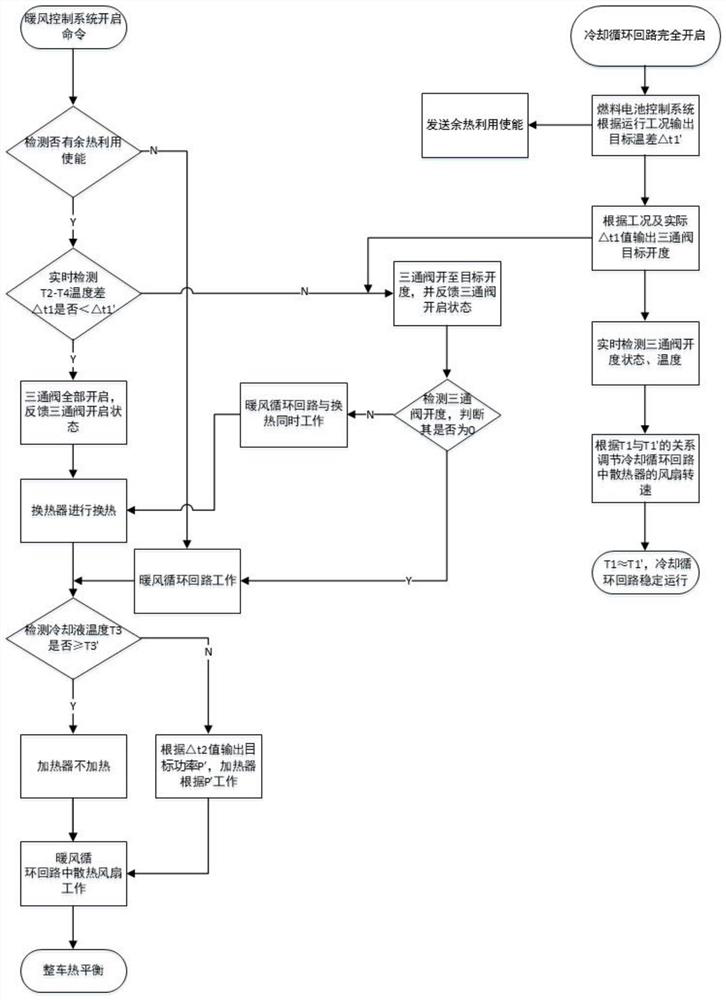

[0042] This embodiment provides a thermal management method, see attached figure 1 Attach figure 2 Attachmentimage 3 The thermal management control method includes:

[0043] The heat exchange of the cooling cycle loop and the cooling cycle loop is adjusted by the heat transfer loop. The heat exchange circuit and the cooling circulation circuit are heat exchange by the heat exchanger 3; the heat transfer circuit and the warm air circulation are controlled by the three-way valve 11. Circuit connection;

[0044] According to the temperature parameter relationship of the cooling cycle loop and the warm air circulation loop, the liquid flow in the line of the heat transfer circuit and the heating loop is adjusted.

[0045] In the present embodiment, three heat dissipation circulation circuits are included, and the cooling cycle circuit is used to cool the fuel cell stack, and the other is that the warm air circulation circuit is used to provide warm air to the whole vehicle; the third ...

Embodiment 2

[0075] Based on the same inventive concept, the embodiment of the present invention also provides a thermal management control system, and since the principle of the problem solving the heat management control system is similar to the thermal management control method of the foregoing embodiment, the implementation of the present embodiment can see the aforementioned heat The implementation of the management control method is not repeated.

[0076] This embodiment provides a thermal management control system including a cooling circulation loop, a warm cycle circuit and a heat transfer circuit; the heat transfer circuit and the cooling cycle circuit achieve heat exchange by heat exchanger 3; The heat transfer circuit and the heating circulation circuit pass through the opening degree of the tube in the pipeline;

[0077] The thermal management control system controls the three-way valve opening according to the temperature parameter relationship of the cooling cycle loop and the w...

Embodiment 3

[0094] Based on the same inventive concept, the embodiment of the present invention further provides a fuel cell vehicle, since the principle of the problem solving the fuel cell vehicle is similar to the thermal management control system of the foregoing embodiment, so the implementation of the present embodiment can see the aforementioned thermal management The implementation of the control system is not repeated.

[0095] Embodiments of the present invention provide a fuel cell vehicle including a thermal management control system of a fuel cell vehicle as described in any embodiment.

[0096] In the present embodiment, the warm air circulation loop can be controlled by the vehicle hot air system, and the cooling cycle circuit is controlled by the fuel cell system, and the thermal management control of the vehicle is achieved through the interaction of the vehicle hot air system and the fuel cell system.

[0097] In the embodiment of the present invention, a tube-shell heat exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com