Tibia prosthesis implanted and fused with tibia-talar joint

A tibial and joint technology, applied in the field of artificial prosthesis replacement, can solve the problems of not taking into account the complexity of the human bone condition, the time-consuming biological fixation, and the slow bone growth time, etc., to achieve convenient surgery, prevent relative movement, The effect of increasing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

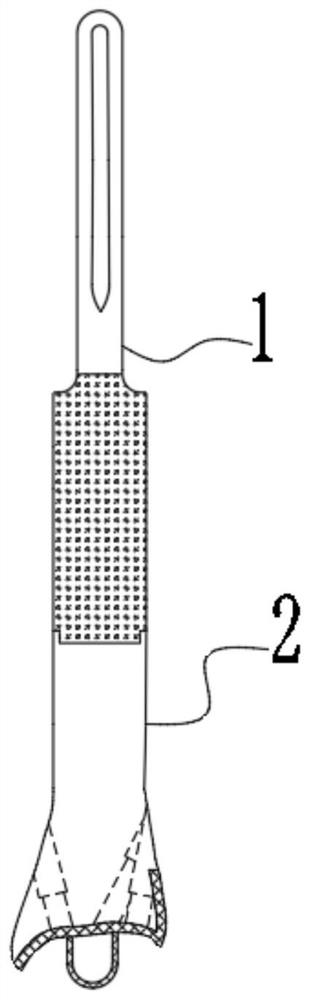

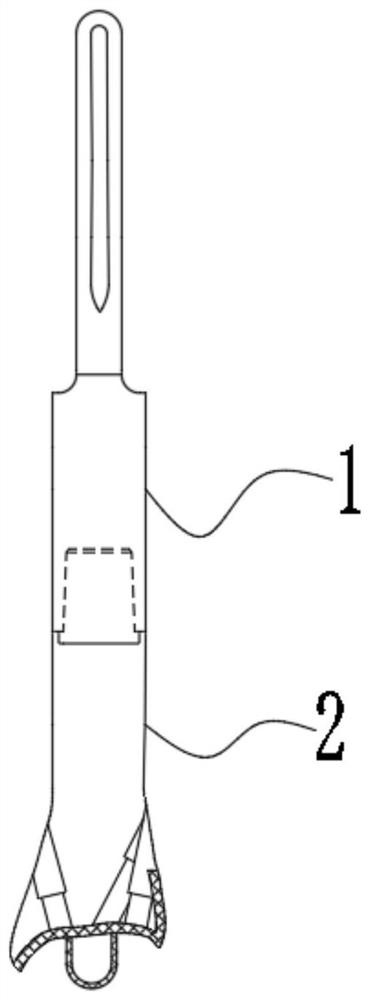

[0046] The purpose of this embodiment is to provide a tibial prosthesis implanted in the fusion tibiotalar joint, according to figure 1 , figure 2 , Figure 5 shown, including

[0047] The tibial medullary pin 1 is used to insert its insertion end into the medullary cavity of the tibial proximal end 3;

[0048] Tibial distal fixation body 2, one end of which is connected with the tibial medullary needle 1, and the other end is connected with the tibial distal end through a locking nail;

[0049] Wherein, the end surface of the distal tibial fixation body 2 near the distal tibia is provided with a protruding post 21 for inserting into the talus 4 .

[0050] In a specific implementation process, the height of the upright column 21 is 10-15 mm, so as to avoid damage to the bone by the prosthesis. The tibial marrow needle 1 is made of non-toxic forged titanium alloy material, which can reduce the toxic damage of the prosthesis to human cells;

[0051] The preparation princip...

Embodiment 2

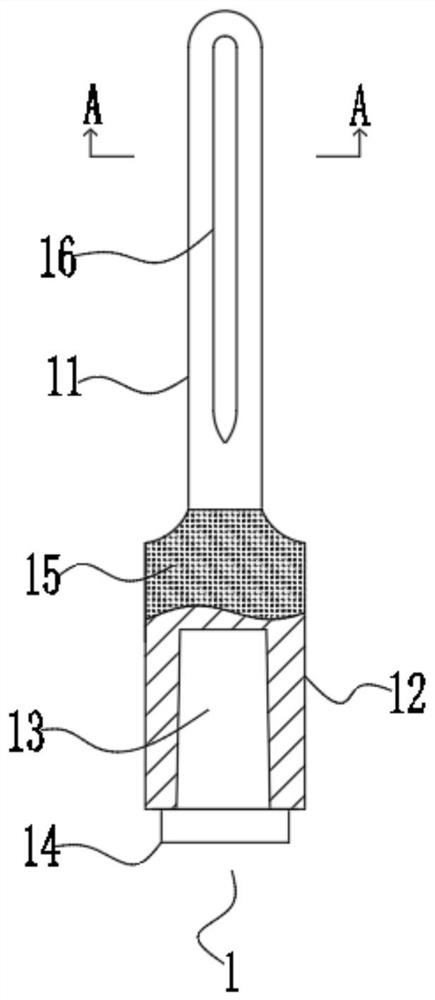

[0055] A tibial prosthesis implanted and fused into the tibiotalar joint according to Embodiment 1, according to image 3, Figure 5 As shown, the tibial needle 1 includes a needle insertion part 11 and a needle connection part 12 integrally formed therewith. The upper end of the needle connection part 12 is connected with the needle insertion part 11, and the lower end is connected with the tibia. The distal fixation body is connected with 2 cones;

[0056] Wherein, the end of the medullary needle connecting portion 12 close to the distal tibial fixation body 2 is provided with a taper hole 13, and the end of the distal tibial fixation body 2 away from the column 21 is provided with the taper hole 13. The tapered column 22 that is adapted to connect.

[0057] The medullary needle insertion part 11 is used to connect the medullary cavity of the proximal end of the tibia 3, and the reserved length of the backbone and the diameter of the medullary cavity are measured according...

Embodiment 3

[0061] According to a kind of tibial prosthesis of fusion tibiotalar joint described in embodiment two, according to image 3 , Figure 5 As shown, one end of the medullary needle connecting portion 12 close to the distal tibial fixation body 2 is provided with a protruding portion 14 with an arc-shaped cross-section along its circumference;

[0062] The end of the distal tibial fixation body 2 facing away from the column 21 is provided with a recessed part 23 adapted to the protruding part 14 for connecting the medullary nail connection part 12 with the distal tibial fixation body 2 .

[0063] The beneficial effect of above-mentioned technical scheme is:

[0064] The matching design of the protruding part 14 on the medullary needle connecting part 12 and the concave part 23 on the distal tibial fixation body 2 can make the prosthesis assembly more convenient and accurate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com